- Hits: 2989

ICPT-FuelCell

TODO 2025: H2 Compressor Integration:

The hydrogen gas will be stored in a gas tank under pressure of 10 bars

compressor with normal gas filter

gas tank capable of holding 10 bar of hydrogen

Active carbon filter tubes for removing oil impurites in the hydrogen gas caused by the compressor

This is essential to protect the fuel cell components insuring longer life span

| Documentation of Master Thesis Razan Kaddour 2024 |

|

|

|

| Poster of Fuel Cell - Electrolysis System (master project Razan Kaddour) (pptx) |

|

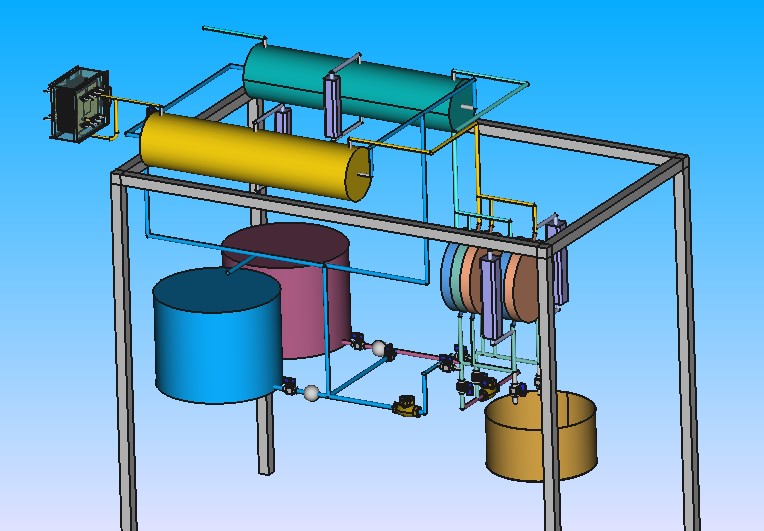

| Fuel Cell - Electrolysis System (FreeCAD file) |

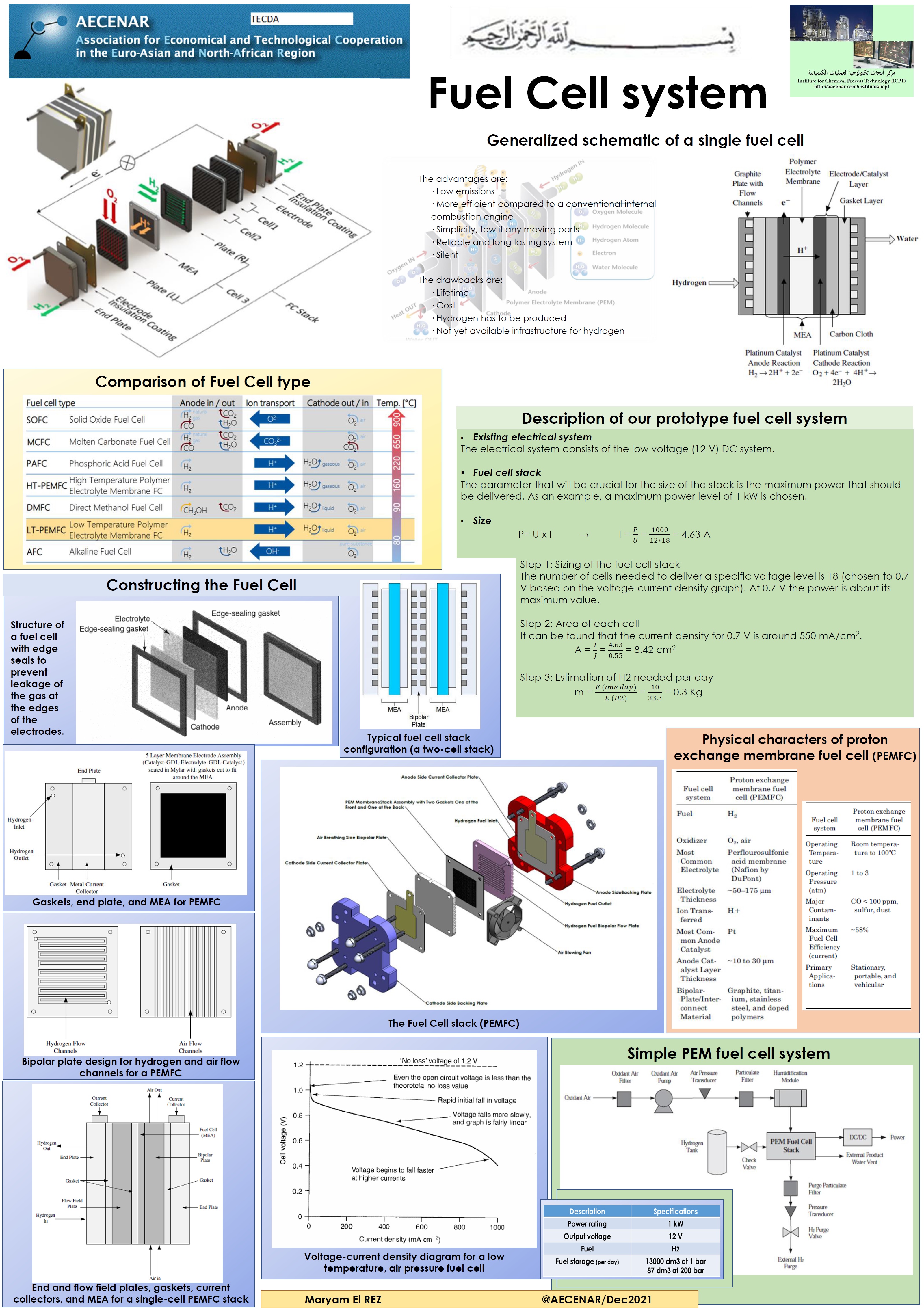

The concept of Fuel Cell

05012022_ICPT_fuel cell (docx)

05012022_poster fuel cell (pptx)

Some estimates from MetaAI:

[3:20 PM, May 17, 2025] Samir Mourad: The construction costs for a 25 kW alkaline electrolyzer fuel cell system can vary, but I can give you some general information.

Cost Factors

The costs of an alkaline electrolyzer fuel cell system depend on various factors, such as:

- Power: Costs increase with increasing power.

- Efficiency: Higher efficiency can lead to higher costs.

- Materials: Using higher-quality materials can increase costs.

- Manufacturing capacity: Costs can be reduced through economies of scale.

Cost Estimates

Some cost estimates for alkaline electrolyzer fuel cell systems are:

- Small systems (1-5 kW): €30,000-70,000

- Medium systems (5-25 kW): €70,000-200,000

- Large systems (25-100 kW): €200,000-500,000

For a 25 kW system, the cost could range from €150,000 to €300,000.

Other Costs

It is important to note that construction costs are only a portion of the total cost. Additional costs may be incurred for:

- Operation and Maintenance: Costs for operating and maintaining the system.

- Hydrogen Production: Costs for producing hydrogen.

- Infrastructure: Costs for installing and integrating the system.

Conclusion

Construction costs for a 25 kW alkaline electrolyzer fuel cell system can vary, but estimates range from €150,000 to €300,000. It's important to consider the overall cost and economic viability of the system.

[3:23 PM, May 17, 2025] Samir Mourad: Component List

[3:23 PM, May 17, 2025] Samir Mourad: A component list for a 25 kW alkaline electrolyzer fuel cell system could look like this:

Electrolyzer

- Alkaline electrolyzer: 1 unit

- Electrodes: 2 units (anode and cathode)

- Electrolyte: Alkaline solution (e.g., KOH)

- Cell design: Bipolar or monopolar cells

Fuel Cell

- Alkaline fuel cell: 1 unit

- Electrodes: 2 units (anode and cathode)

- Electrolyte: Alkaline solution (e.g., KOH)

- Cell design: Bipolar or monopolar cells

Peripherals

- Hydrogen storage: 1 unit

- Oxygen storage: 1 unit

- Hydrogen purification system: 1 unit

- Oxygen purification system: 1 unit

- Cooling system: 1 piece

- Control system: 1 piece

Safety systems

- Hydrogen sensors: 2-3 pieces

- Oxygen sensors: 2-3 pieces

- Pressure relief valves: 2-3 pieces

- Emergency shutdown: 1 piece

Other components

- Electrical connections: 1 set

- Piping: 1 set

- Valves: 1 set

- Pumps: 1-2 pieces

It is important to note that the specific components and their quantity may vary depending on the system design and requirements. It is advisable to have a professional prepare a detailed system design and component list.

[15:23, May 17, 2025] Samir Mourad: Component design

[15:23, May 17, 2025] Samir Mourad: The component design for a 25 kW alkaline electrolyzer fuel cell system depends on various factors, such as the desired power, efficiency, and operating conditions. Here are some general considerations for component design:

Electrolyzer

- Cell design: Bipolar or monopolar cells, depending on requirements and efficiency

- Electrode material: Nickel or other suitable materials

- Electrolyte: Alkaline solution (e.g., KOH) with a concentration of 25-30%

- Operating temperature: 60-80°C

- Pressure: Atmospheric pressure or higher, depending on requirements

Fuel Cell

- Cell design: Bipolar or monopolar cells, depending on requirements and efficiency

- Electrode material: Nickel or other suitable materials

- Electrolyte: Alkaline solution (e.g., KOH) with a concentration of 25-30%

- Operating temperature: 60-80°C

- Pressure: Atmospheric pressure or higher, depending on requirements

Hydrogen storage

- Storage volume: Depends on the desired storage capacity and operating pressure

- Pressure: Up to 30 bar or higher, depending on requirements

Oxygen storage

- Storage volume: Depends on the desired storage capacity and operating pressure Operating Pressure

- Pressure: Up to 30 bar or higher, depending on requirements

Cooling System

- Cooling Medium: Water or other suitable cooling media

- Cooling Capacity: Depends on the heat generation in the system

Control System

- Control System: Depends on the requirements and complexity of the system

- Sensors: Temperature, pressure, and flow sensors

Safety Systems

- Hydrogen Sensors: 2-3, depending on requirements and safety standards

- Oxygen Sensors: 2-3, depending on requirements and safety standards

- Pressure Relief Valves: 2-3, depending on requirements and safety standards

It is important that the design of the components is carried out by a specialist who takes the specific requirements and safety standards into account.

[15:25, May 17, 2025] Samir Mourad: Sizing the Components

[15:25, May 17, 2025] Samir Mourad: Sizing the Components for a 25 kW Alkaline