- Hits: 2694

Penicillin Production and Quantification May2023

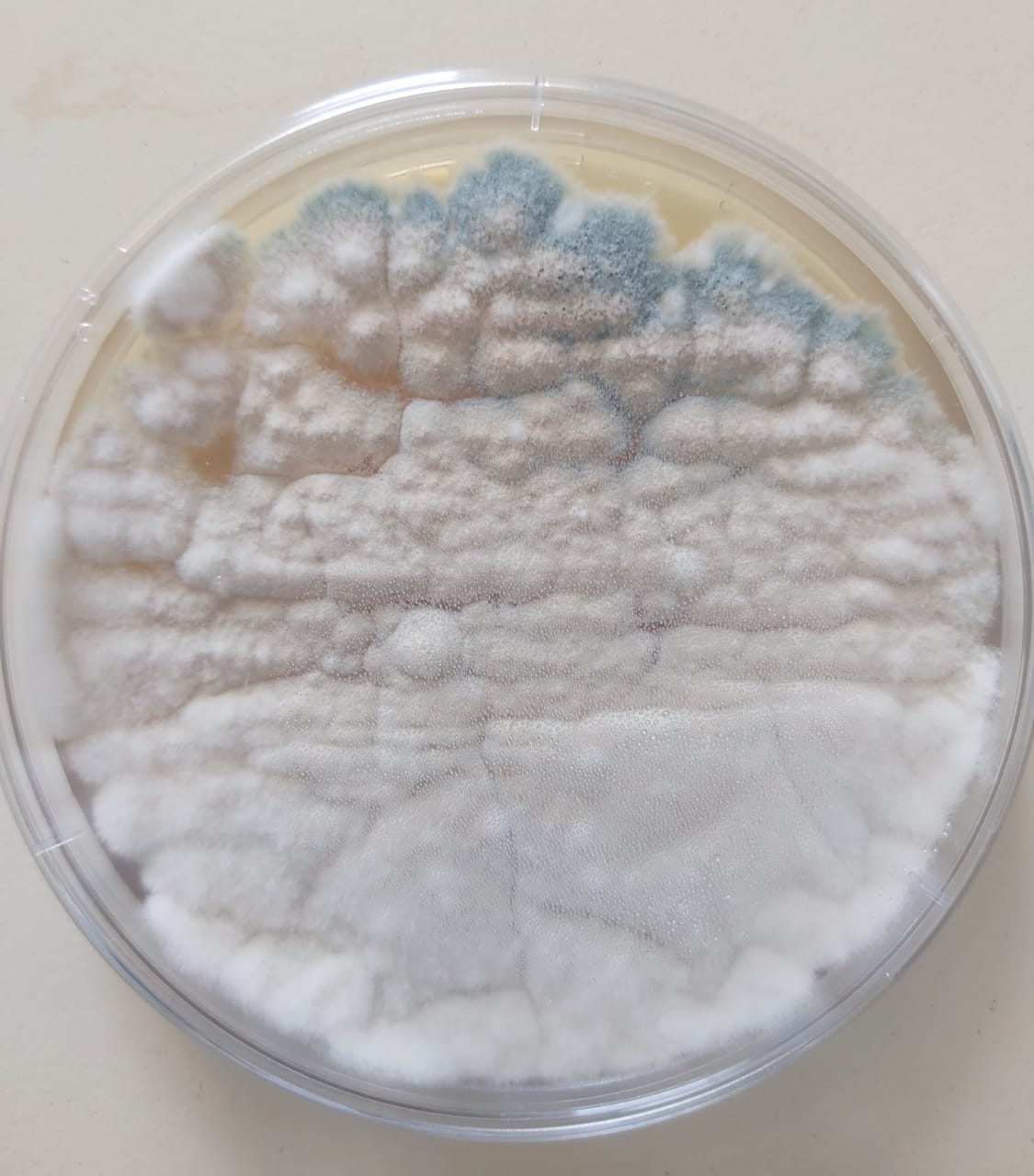

Strain collection

A strain of Penicillium chrysogenum has been preserved at the Doctoral School at the Lebanese University in Tripoli.

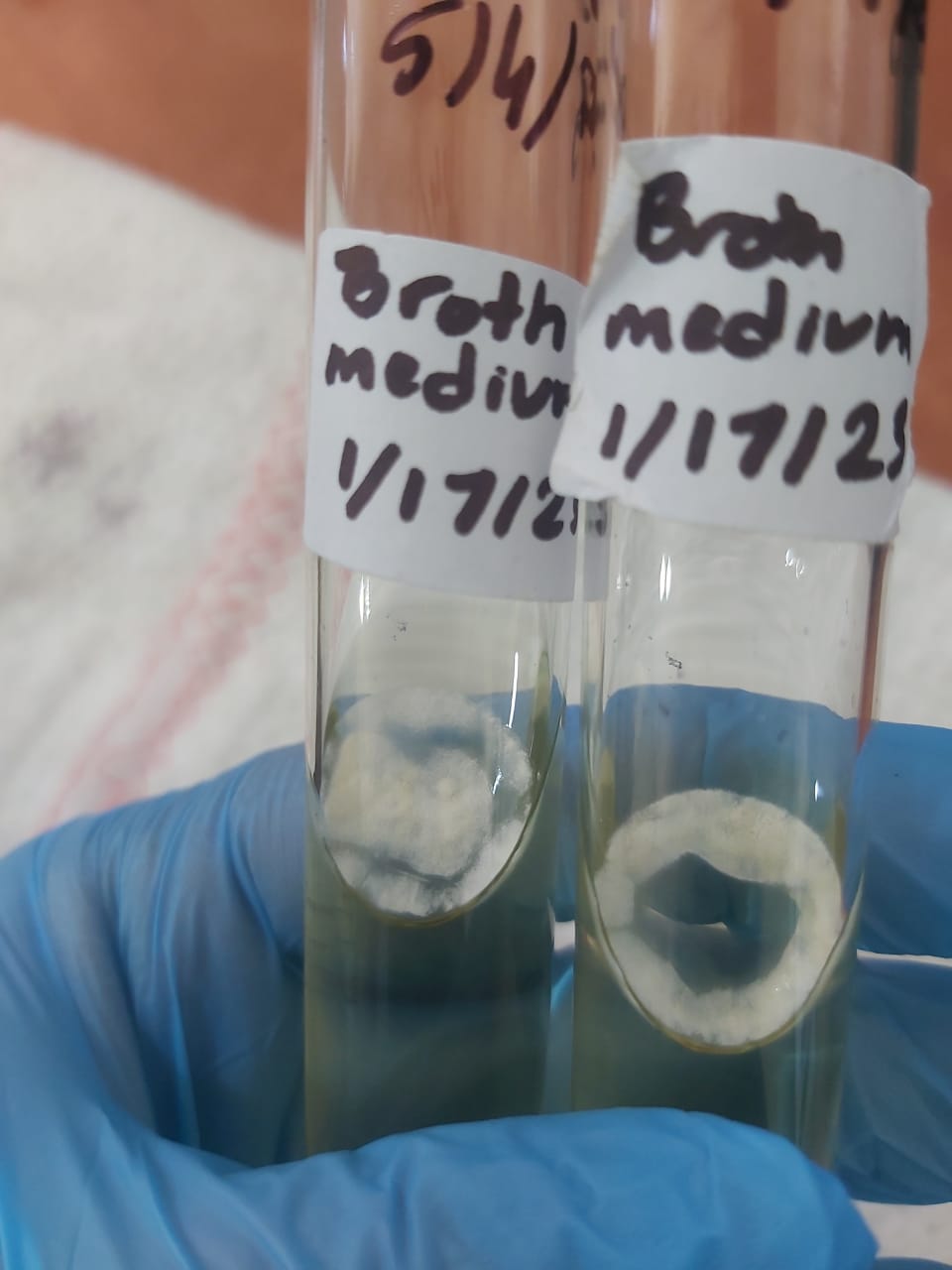

Preparation of the liquid medium (Broth):

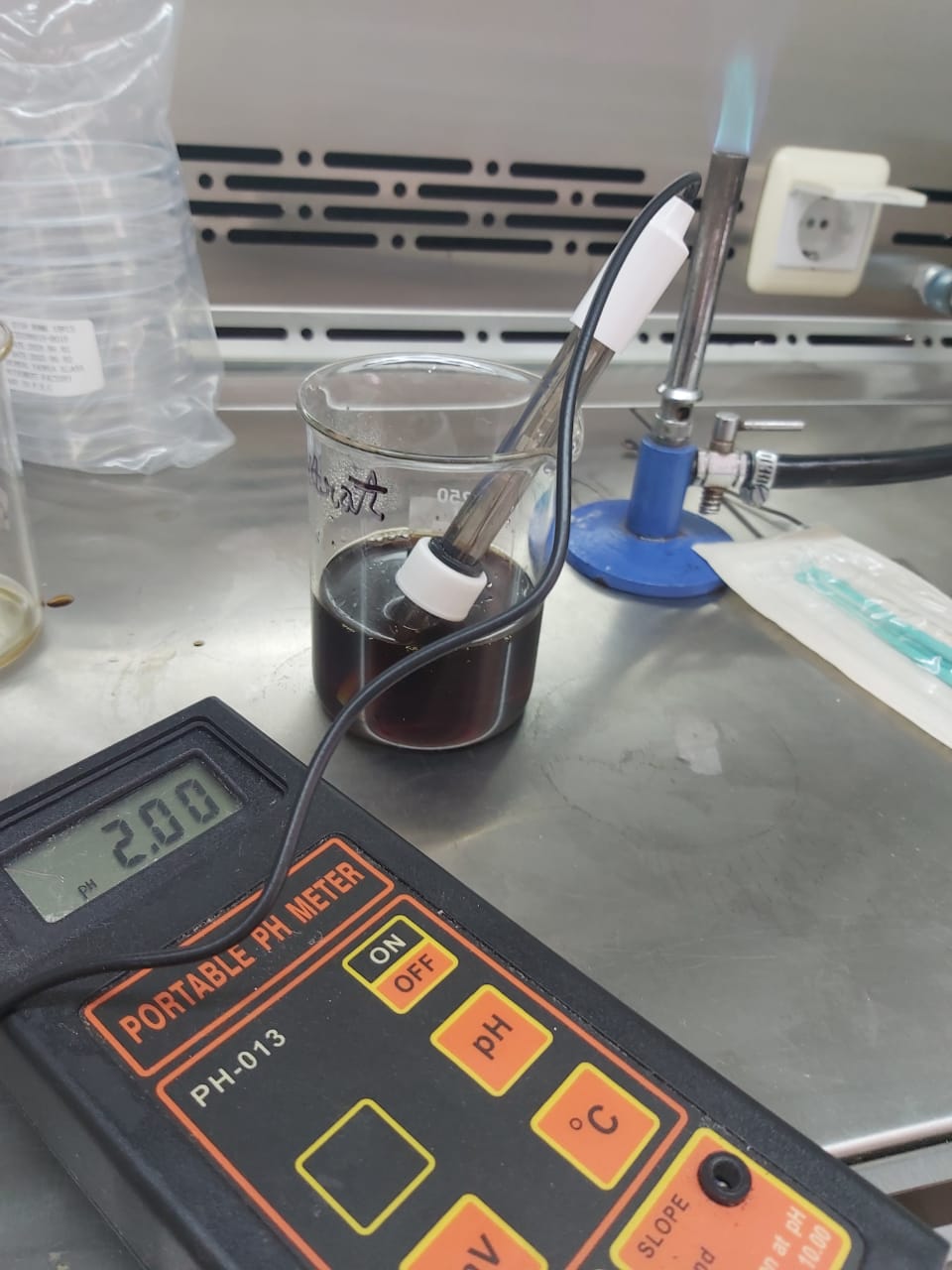

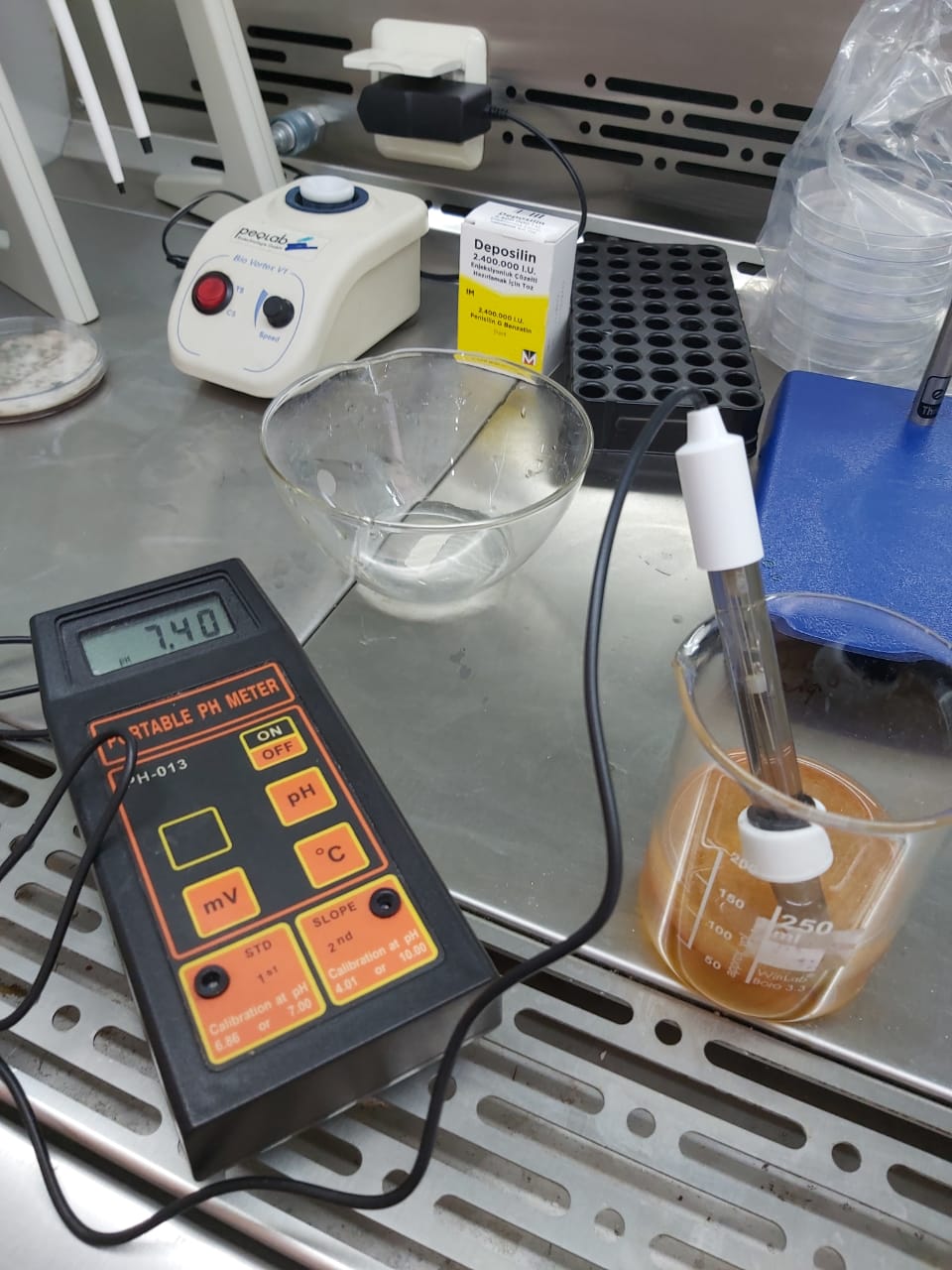

0.5g peptone, 0.1g tryptone, 0.1g glucose, 0.1g yeast extract, 0.25g NaCl, 50ml distilled water were mixed and heated in a beaker. The pH was measured and adjusted to 7 by adding a few ml of H2SO4.

The medium was then placed in tubes, autoclaved for 1h and then cooled.

An inoculum is taken from the strain Penicillium chrysogenum using a sterile loop and then transferred and mixed in the liquid medium. The tube is incubated at room temperature for 4 days.

Constitutes of penicillin G fermentation broth:

|

Media |

Percentage% |

|

Peptone |

4% |

|

Lactose |

3-4% |

|

Glucose |

10% |

|

PAA(Crude Phenylacetic acid) |

0.5% |

|

Yeast extract |

4% |

|

CaCO3 |

1% |

|

Antifoam(corn oil) |

0.25-0.5% |

|

KH2PO4 |

0.4% |

- Prepare the nutrient media in 100ml distilled water.

- Measure the PH and then adjust it to 7 by adding a few ml of H2SO4

- Heat and mix for about 15min

- Autoclave the medium for 1h then cool it down for 30min

- Add the inoculum to the medium

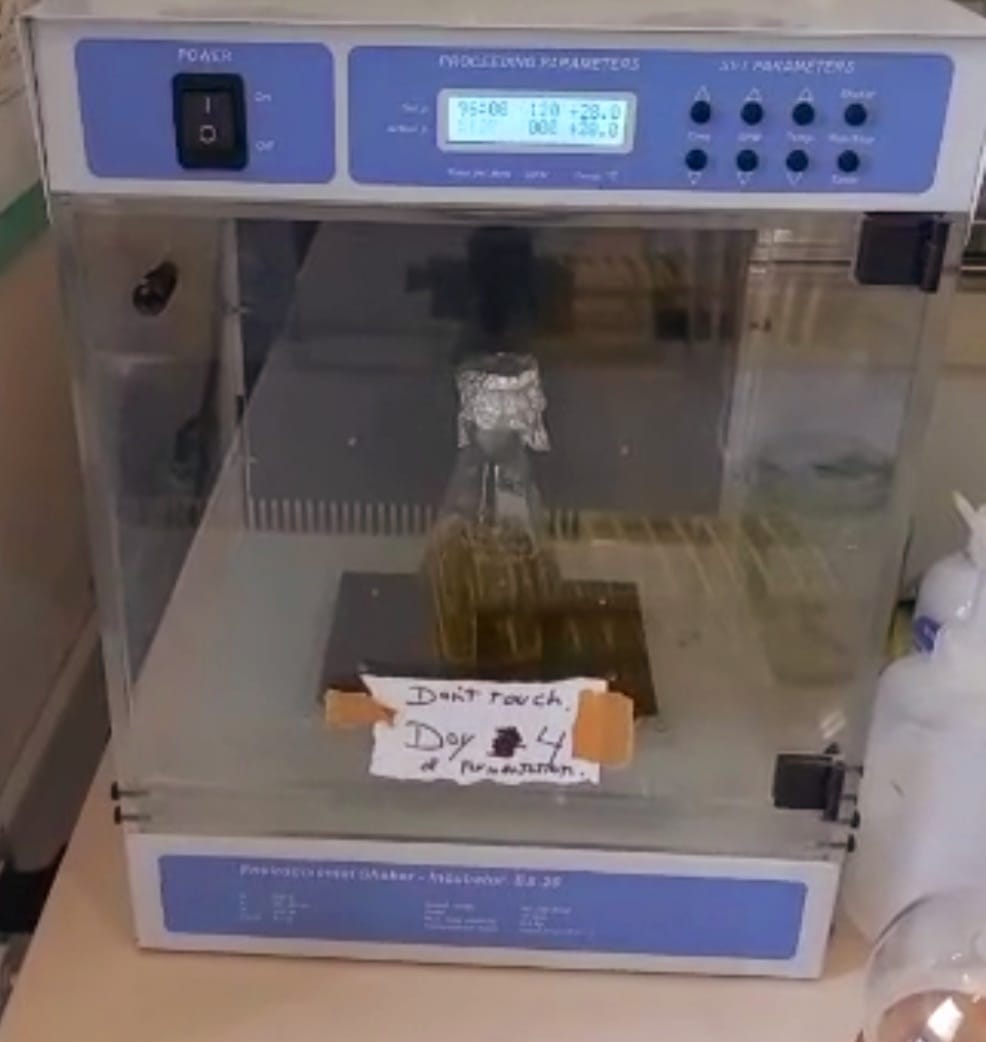

- Incubate the mix at 28˚C for 10 days with shaking (120 RPM)

Filtration and purification:

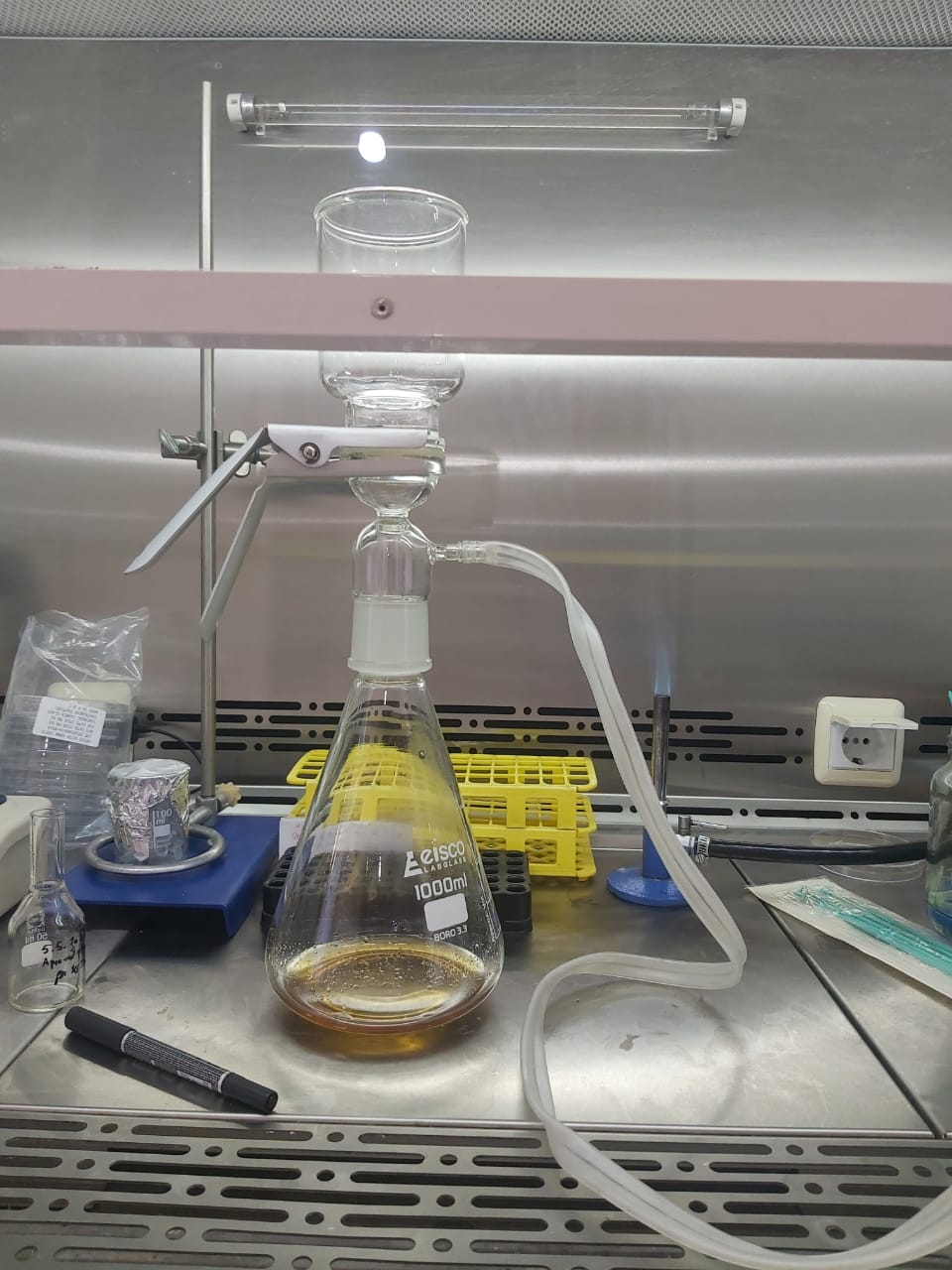

- After 10 days of medium incubation with shaking we proceed to Filtration using a filter whose pores have a diameter of 0.2 µm. The microorganisms are too large and are therefore retained by the filter.

- After filtration, the pH of the filtrate is adjusted to 1.5-2.2 by adding H2SO4 (penicillin ionized in the solution) in order to stop any reaction that could degrade penicillin.

- The filtrate was then kept cold (5-10˚C).

- Add the butyl acetate (1V solvent/2V filtrate) which serves as solvent for separating the organic phase and the aqueous phase(F1) using a separating funnel.

- Add 2% (W/V) phosphate buffer(PB) to the organic phase(F2).

- Adjust the PH to 7.5 by adding NaOH.

- Add 2% (W/V) NaHCO3 in order to carry out the crystallization.

- Cool the solution (F3) at 4˚C about 7 days .

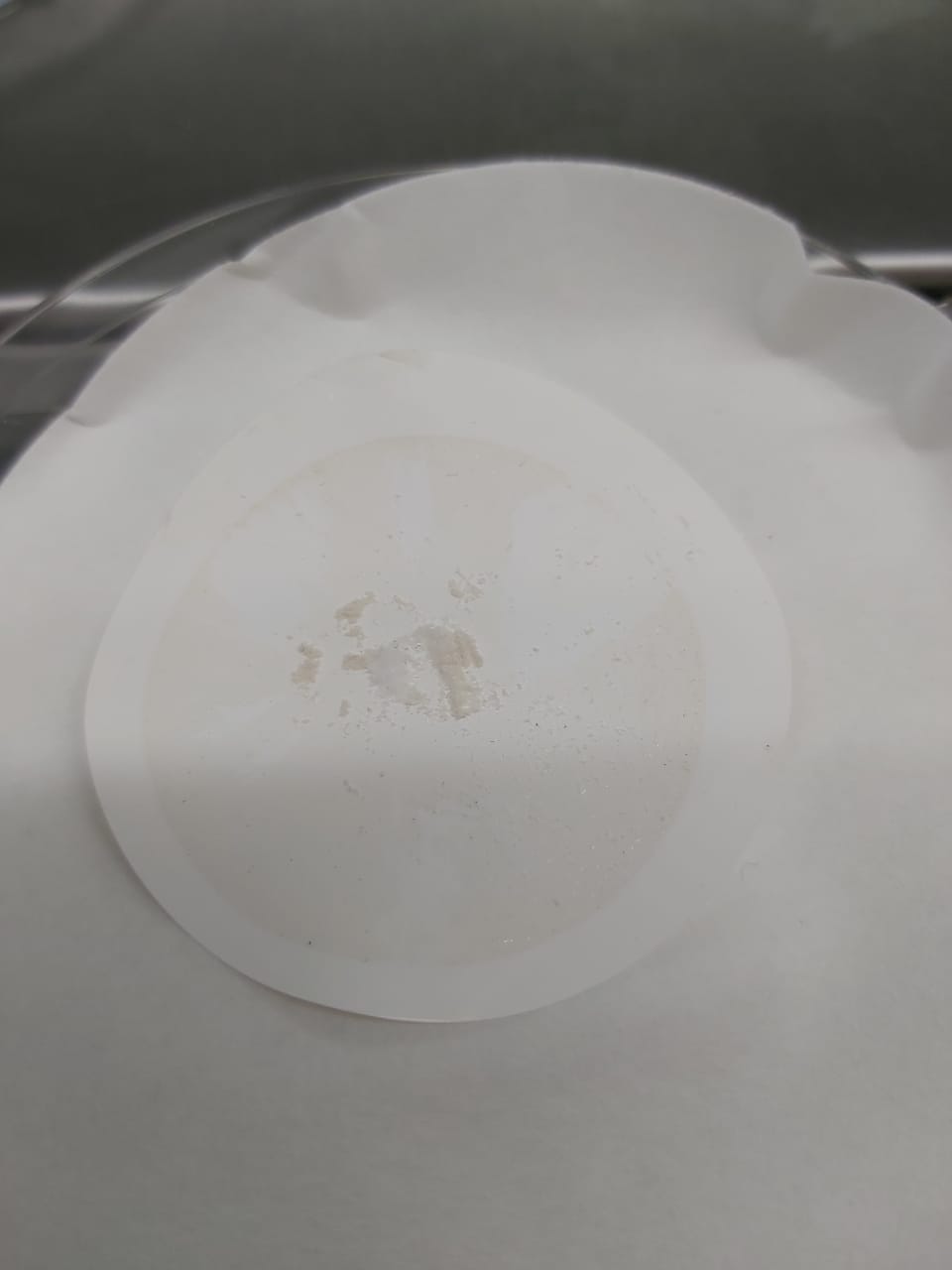

- Filtrate and harvest penicillinG sodium salt.

Results:

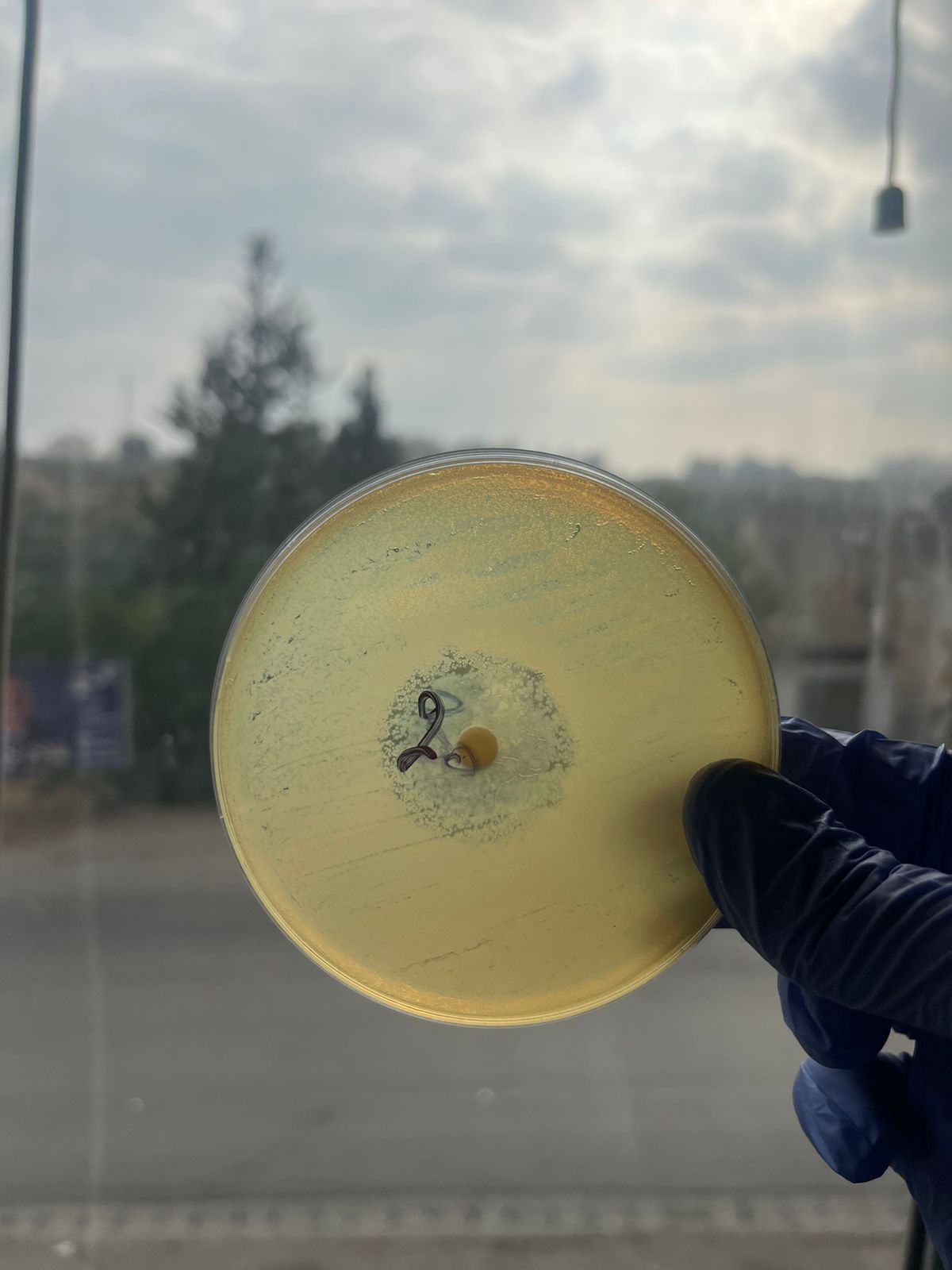

Trial 1:

We obtain clear white powder of crude PenG that will be used later for quantification so the crystallization has succeeded .

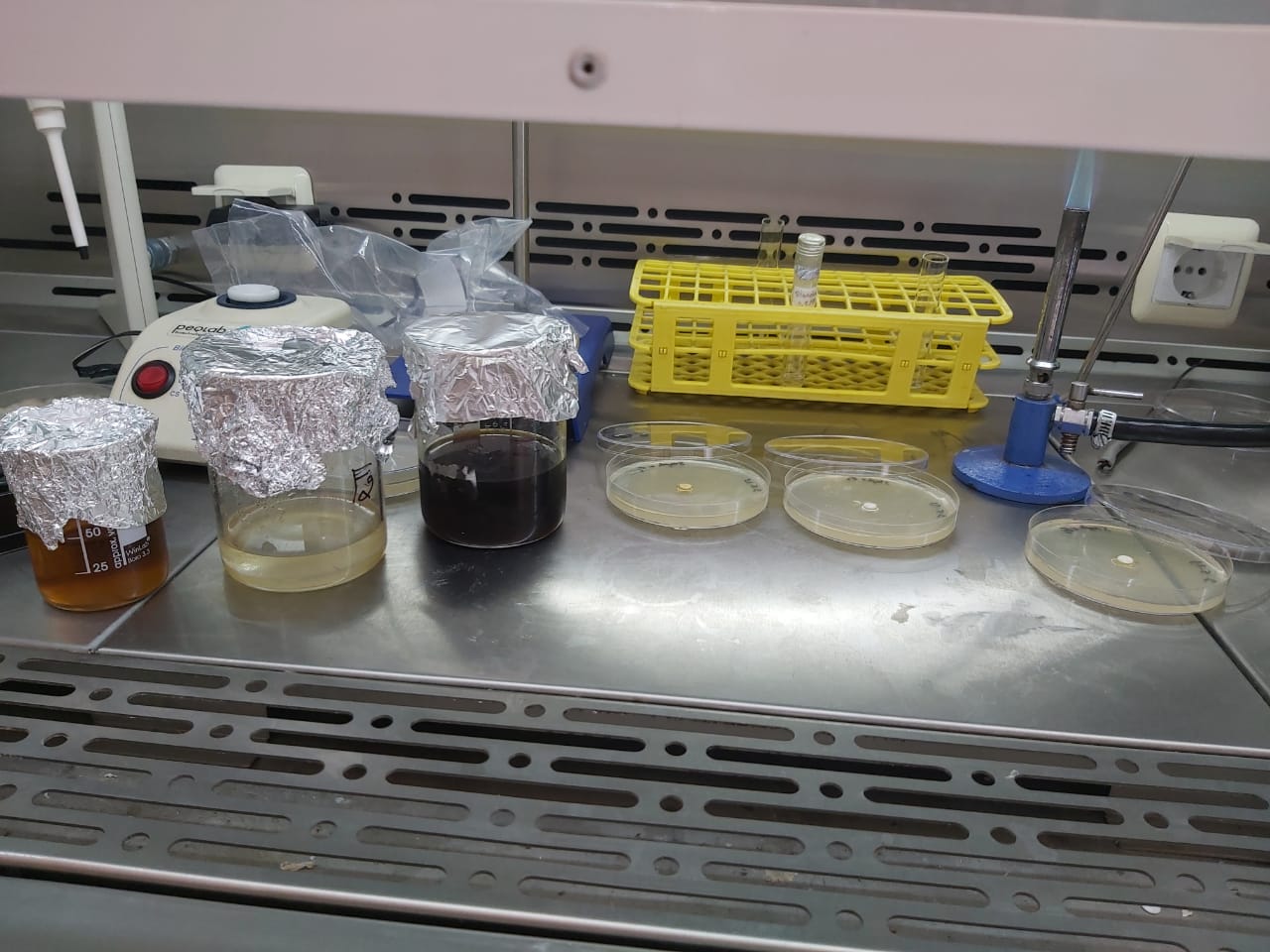

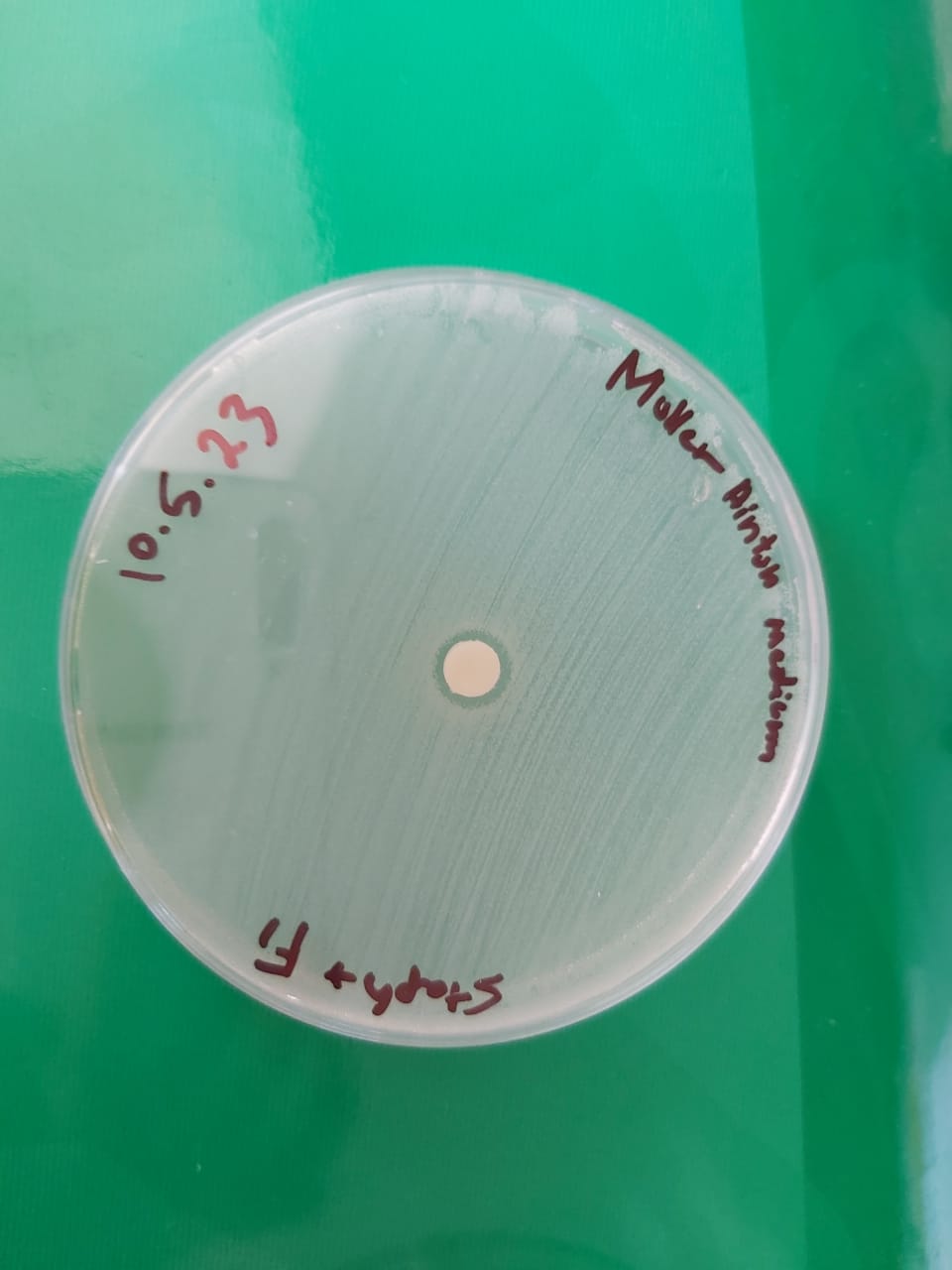

Note that we realize a sensitivity test for:

_F1(Aqueous phase after the organic solvent extraction)

_F2(Organic phase After PB extraction)

_F3(the final solution obtained after organic solvent extraction)

The results show :

A clear zone of inhibition in F1 which means that :

- There is PenG In F1 so we can say that the experiment has succeeded and the PAA produced in the lab is effective.

- Not all the PenG was extracted into the used organic solvent(there is a percentage of PenG loss).

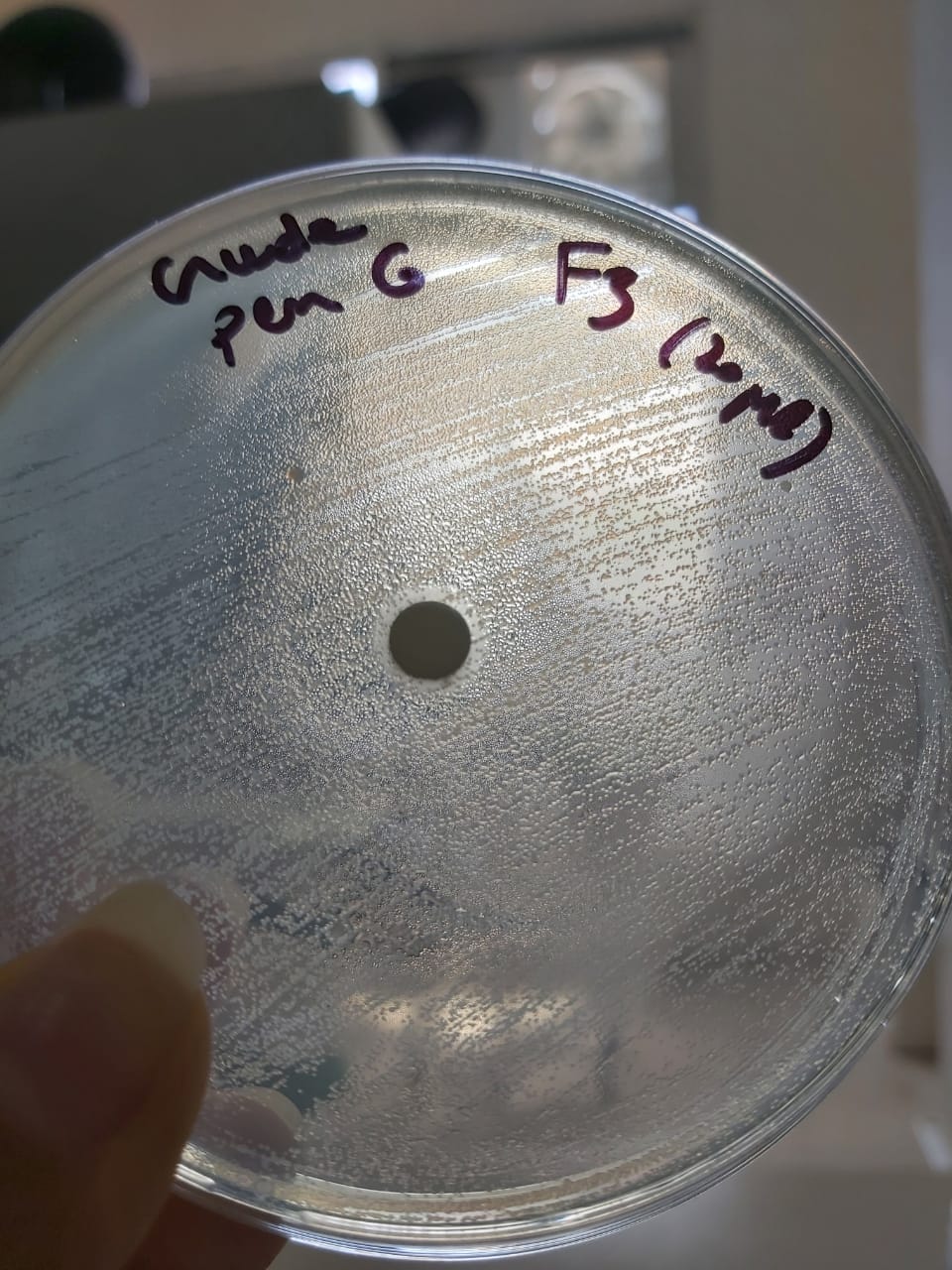

A clear zone of inhibition in F3 which means that :

- There is crude PenG in the final solution so the solvent used is effective.

- The purification has succeeded with a percentage of PenG loss in aqueous phaseF1.

No zone of inhibition in F2 which means that there is no loss of produced PenG in F2.

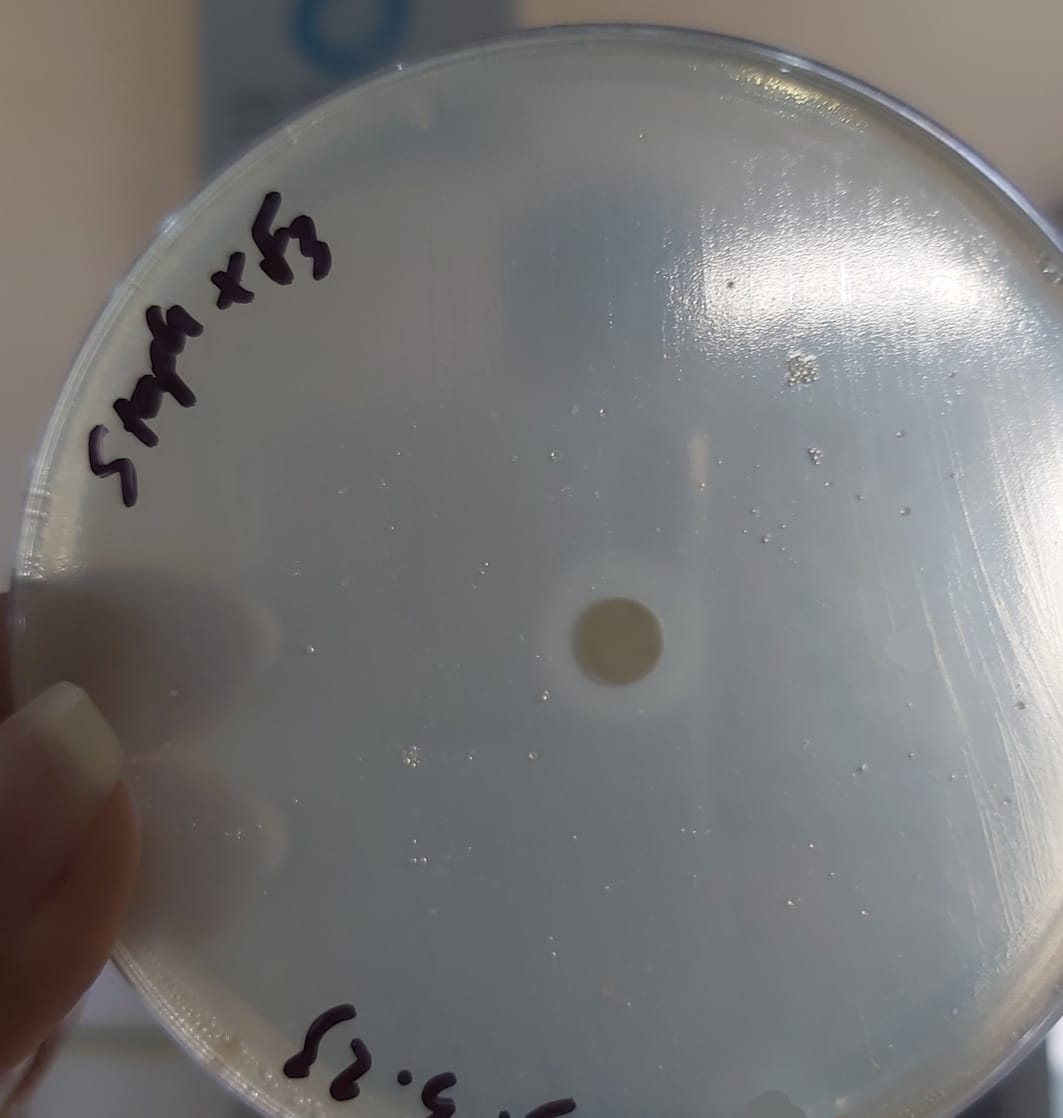

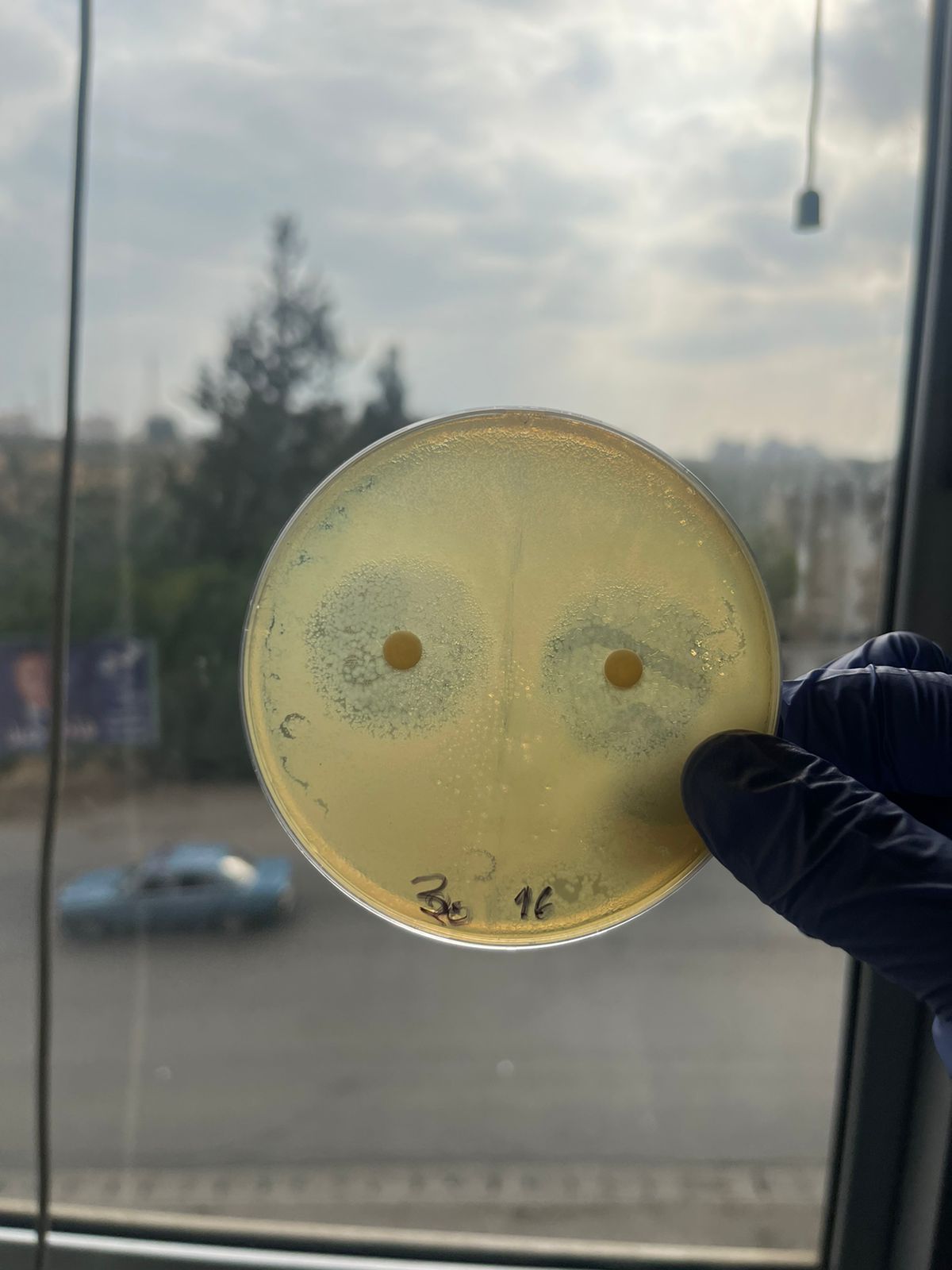

Trial 2:

according to the sensitivity test :

_F1(Aqueous phase after the organic solvent extraction)

_F2(Organic phase After PB extraction)

_F3(the final solution obtained after organic solvent extraction)

Penicillin Quantification (May 2023)

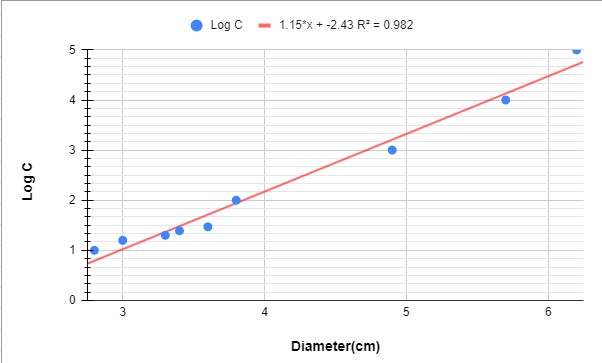

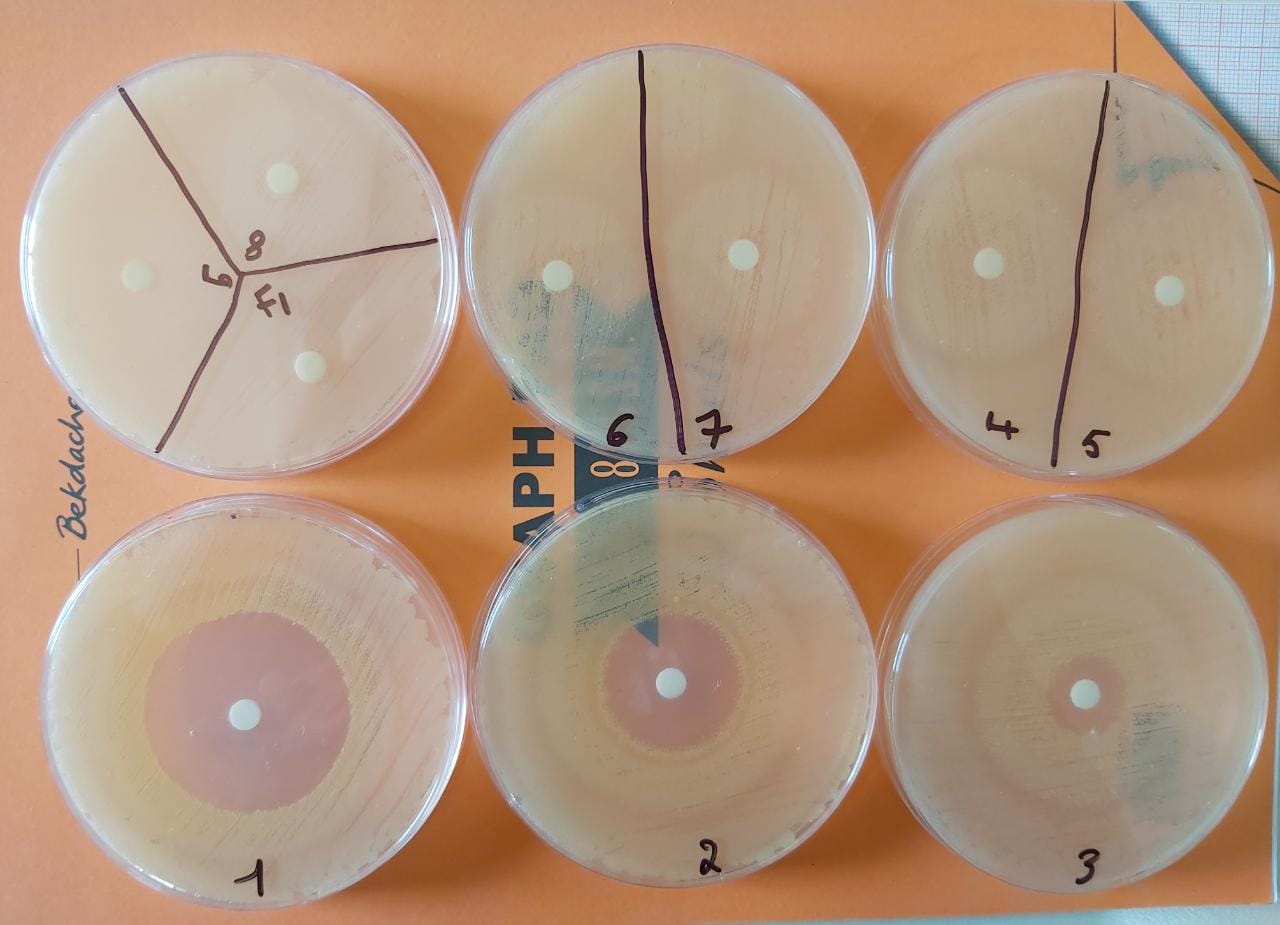

The procedure for quantification is the same as that mentioned before using disc diffusion method leading to a calibration curve helping to calculate the concentration of our crude PenG obtained from F1 and F3 solution:

Quantification of Crude PenG obtained from F1 crystallization:

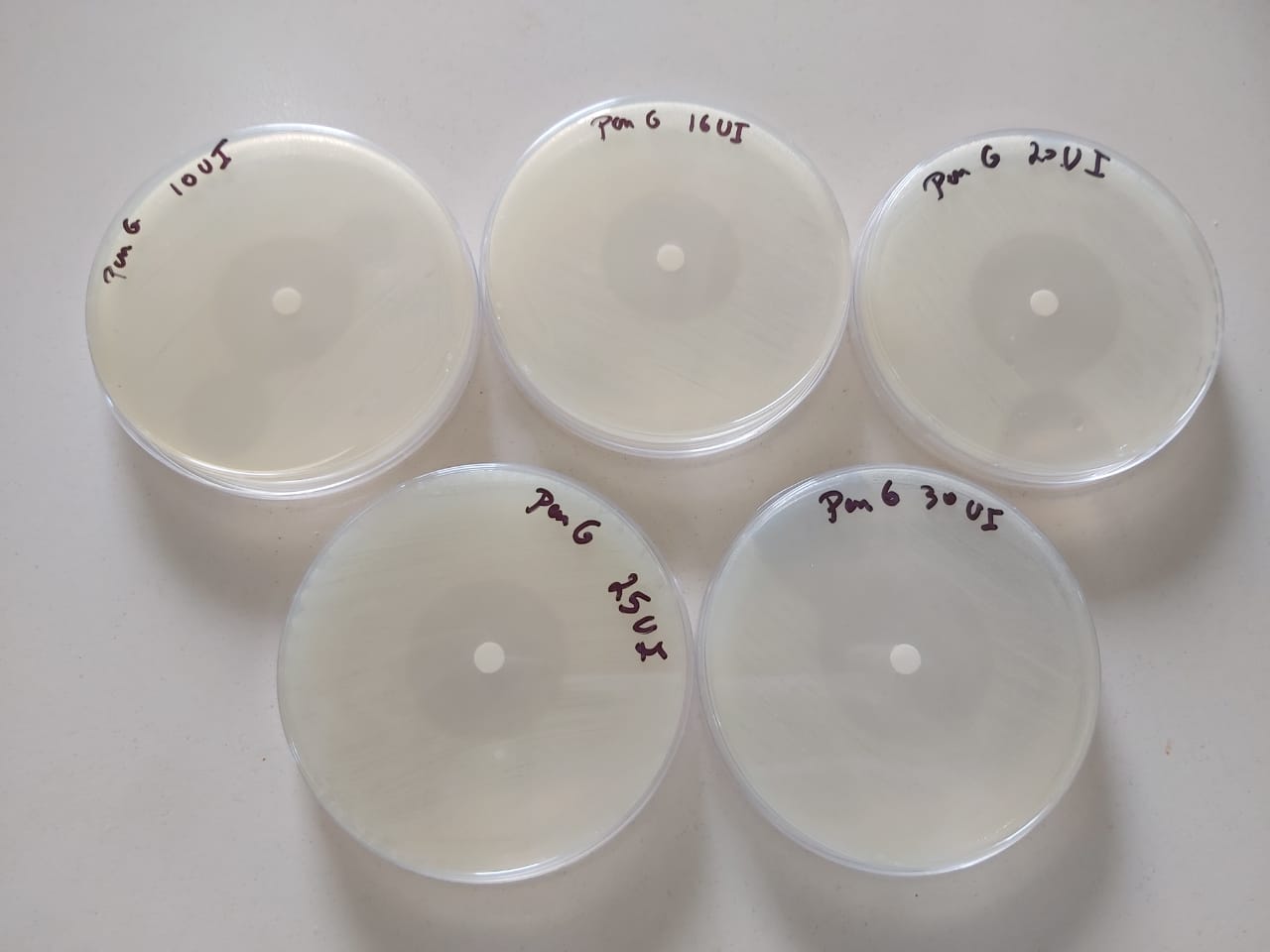

Table1 : Measurements of diameters of bacterial growth inhibition zones for different concentrations of standard dilute commercial penicillinG and F1.

|

Diameter(cm) |

2.8 |

3 |

3.3 |

3.4 |

3.6 |

3.8 |

4.9 |

5.7 |

6.2 |

0.9 |

|

LogC |

1 |

1.2 |

1.3 |

1.39 |

1.47 |

2 |

3 |

4 |

5 |

? |

|

Concentration(mg/ml) |

10 |

16 |

20 |

25 |

30 |

102 |

103 |

104 |

105 |

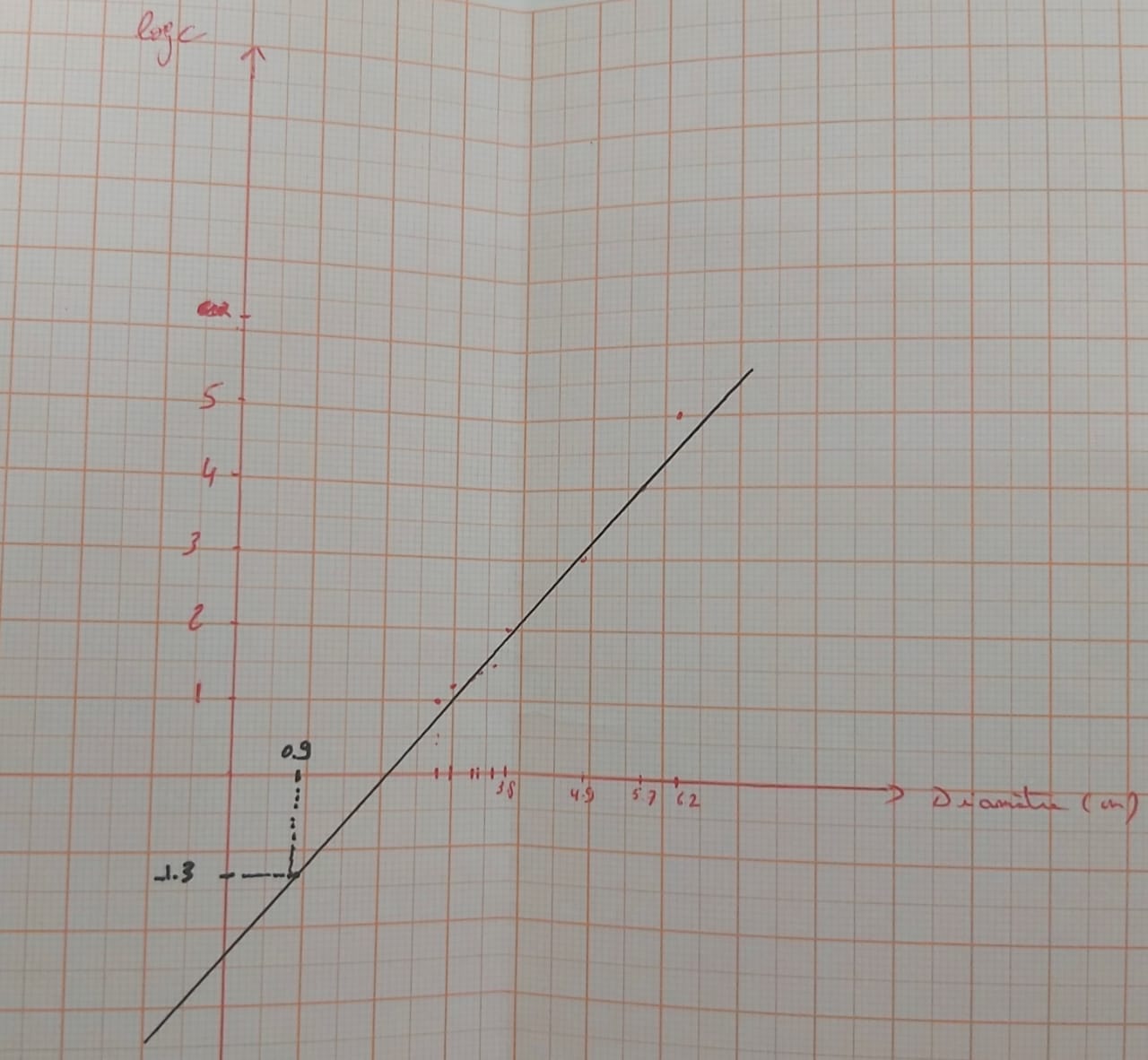

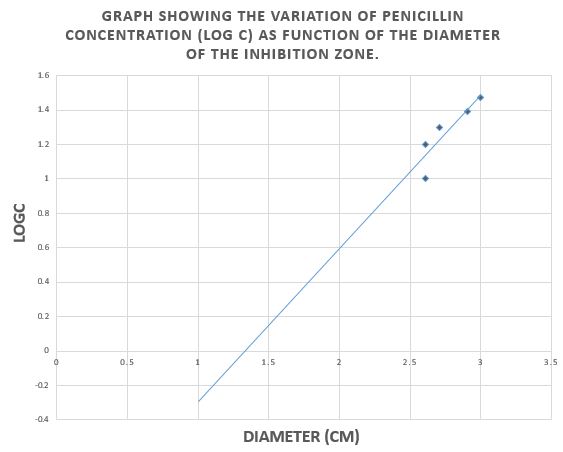

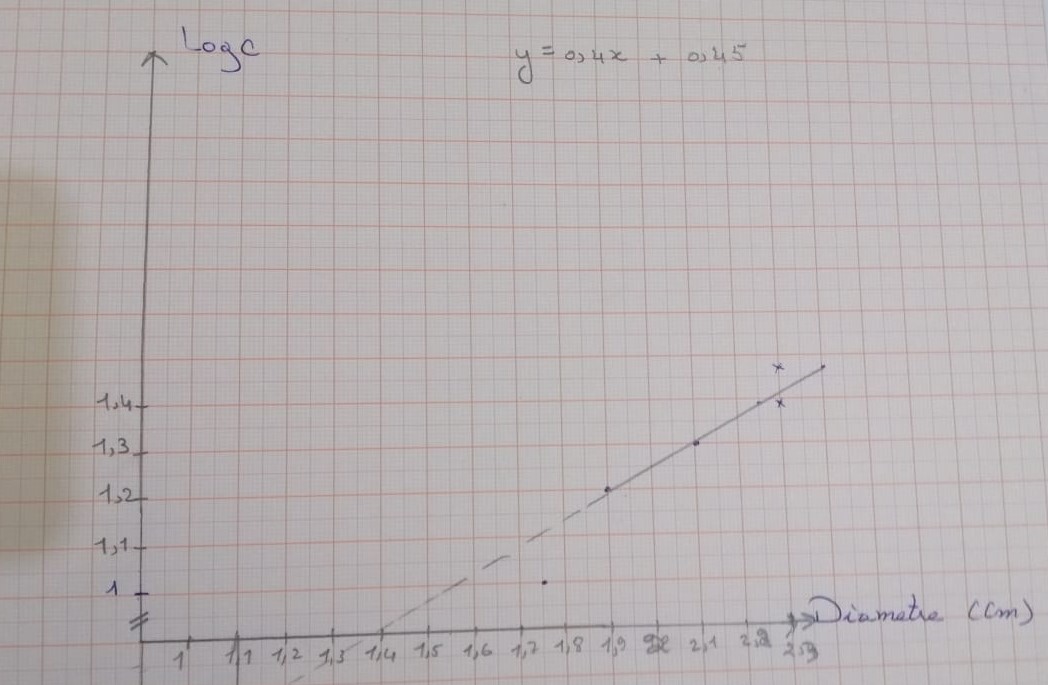

Graph 1: Graph showing the variation of penicillin concentration (LogC) as function of the diameter of the inhibition zone

According to the calibration curve y=1.15x+(-2.43)

So the concentration of PenG in F1 is 0.04mg/ml

Quantification for Crude PenG obtained from F3 crystallization

Table 2 : Measurements of diameters of bacterial growth inhibition zones for different concentrations of standard dilute commercial penicillinG and F3 solution.

|

Diameter(cm) |

3.8 |

3.5 |

3.4 |

3.2 |

3.1 |

0.7 |

|

LogC |

1.47 |

1.39 |

1.30 |

1.20 |

1 |

? |

|

Concentration(mg/ml) |

30 |

25 |

20 |

16 |

10 |

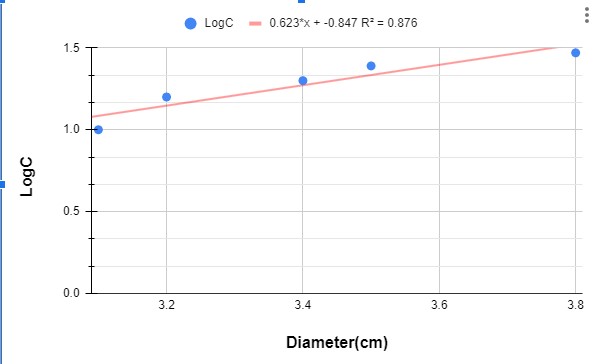

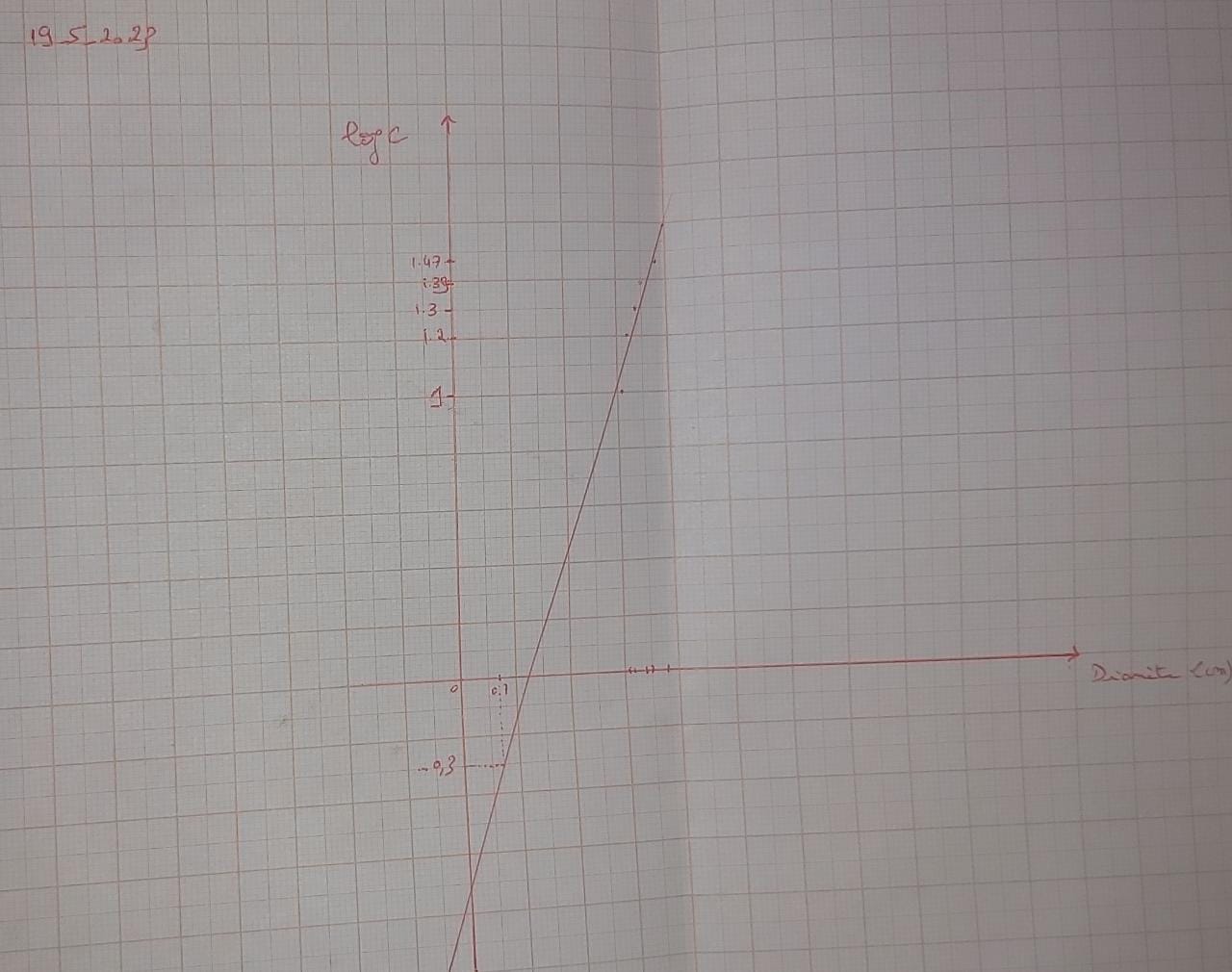

Graph 2 : Graph showing the variation of penicillin concentration (LogC) as function of the diameter of the inhibition zone.

According to the calibration curve y=0.623x+(-0.847)

So the concentration of PenG in F3 is 0.388mg/ml ~ 0.4 mg/ml.

Table showing every step with its duration and working date

|

Steps of preparation |

Working Date |

Duration(Days) |

|

Penicillium culture |

April 19 |

4 days |

|

Fermentation |

April24 to May3 |

10 days |

|

Purification: filtration |

May4 to May5 |

2 days |

|

Crystallization |

May5 to May12 |

7 days |

|

Sensitivity test |

May15 to May16 |

2 days |

|

Quantification/results F1 |

May15 to May16 |

2 days |

|

Sensitivity test Quantification/result F3 |

May18 to May 19 |

2 days |

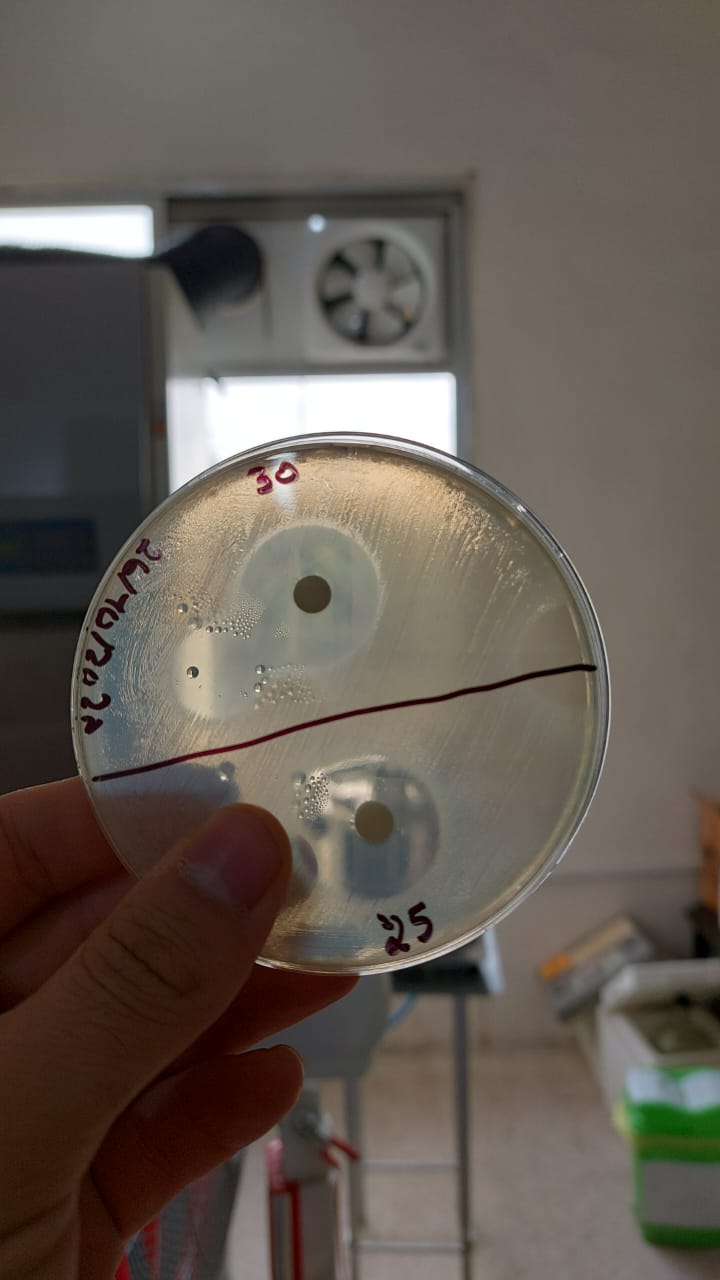

Trial 3:

Same protocol reused in this trial (except: adding PAA : Phenylacetic acid every 24h at 30˚C for the first 48h then decrease the temprature to 25˚C for the rest of the fermentation).

PS : due to disfunction of the incubator we couldn't maintain the temprature ( between 25-30˚C) and solubility of the PAA

RESULTS:

]

| Diameter (cm) | 2.6 | 2.6 | 2.7 | 2.9 | 3 | 1 |

| Log C | 1 | 1.2 | 1.3 | 1.39 | 1.47 | -0.3 |

| Concentration (mg/ml) | 10 | 16 | 20 | 25 | 30 | 0.5 |

Word-docx-Stage-report-ghinwayounes-2023

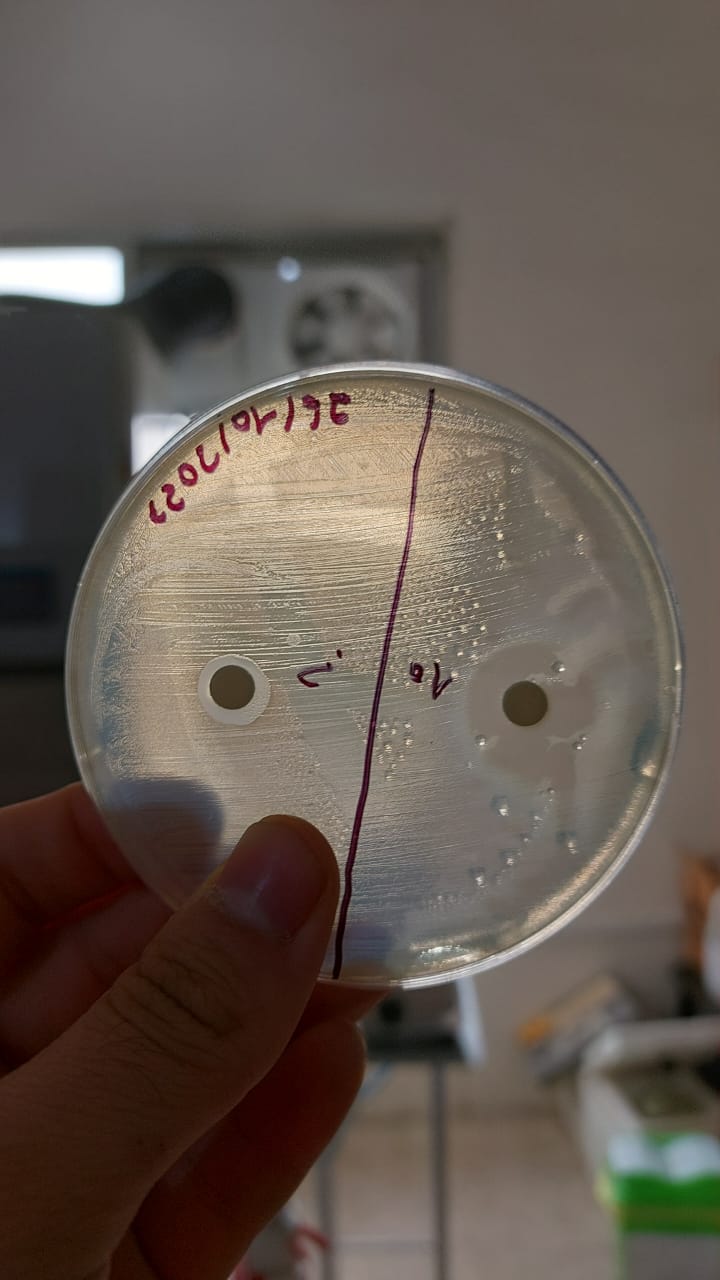

trial 4

Same protocol reused in this trial (except:aeorbie respiration and medium: without glucose , lactose 3g ).

results

|

Diameter (cm) |

2.4 |

2.2 |

2.1 |

1.9 |

1.75 |

1.1 |

|

Log c |

1.47 |

1.39 |

1.30 |

1.20 |

1 |

0.89 |

|

Concentration(mg/ml) |

30 |

25 |

20 |

16 |

10 |

7.76 |

Graph showing the variation of penicillin concentration (LogC) as function of the diameter of the inhibition zone.