- Hits: 1586

003: Aspirin Production System Test (Water test)

|

Step |

Step Description |

Results |

|

Precondition |

System is OFF |

|

|

TURNING ON the system |

Turn ON the control panel

|

The system is ON |

|

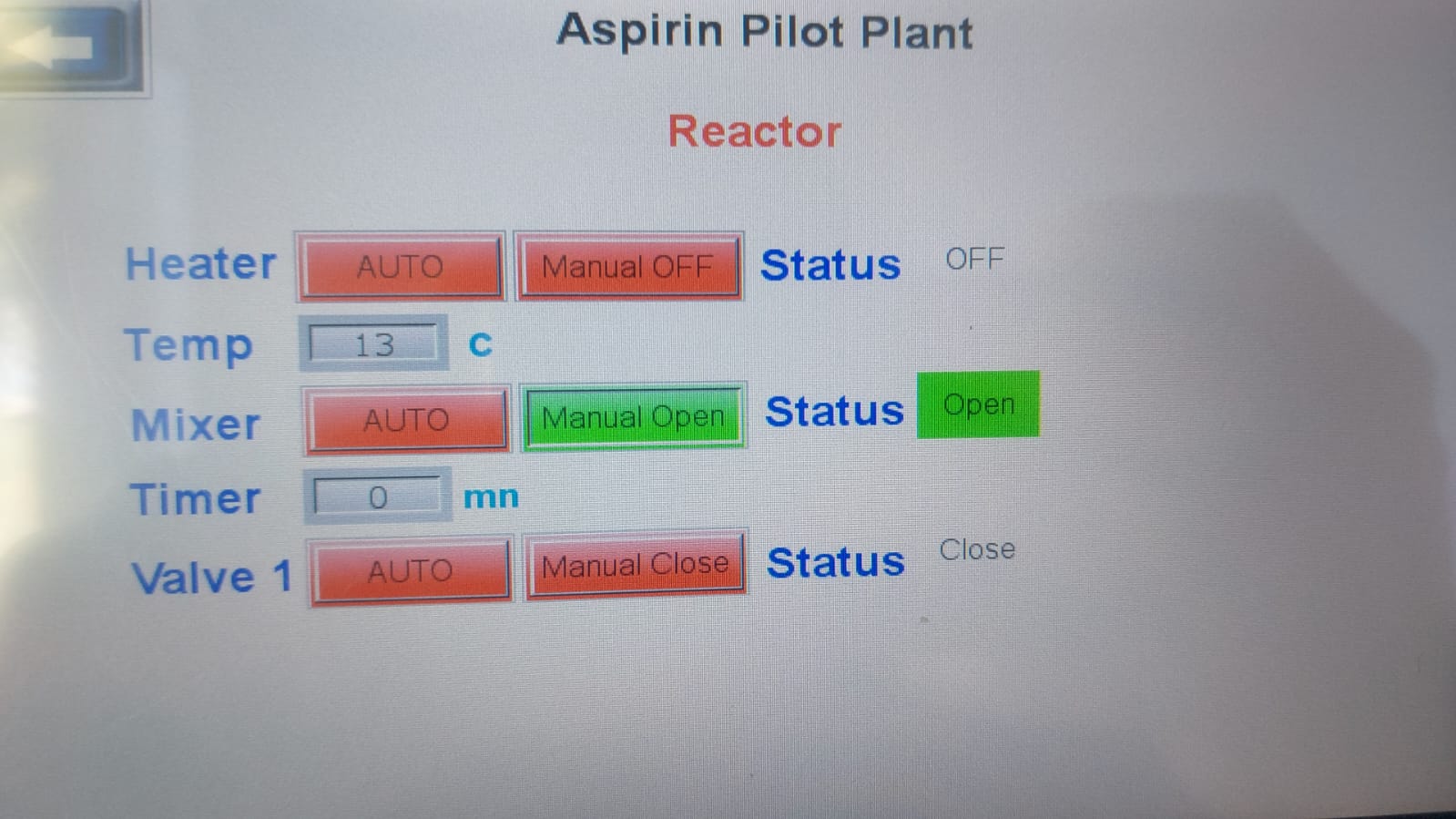

Switch on the mixer 1 (tank 1 : Reactor) |

Turn on the mixer 1 from the control panel (Reactor--->Mixer ON) |

Mixer 1 is ON and start Mixing the Water (Reactor) |

|

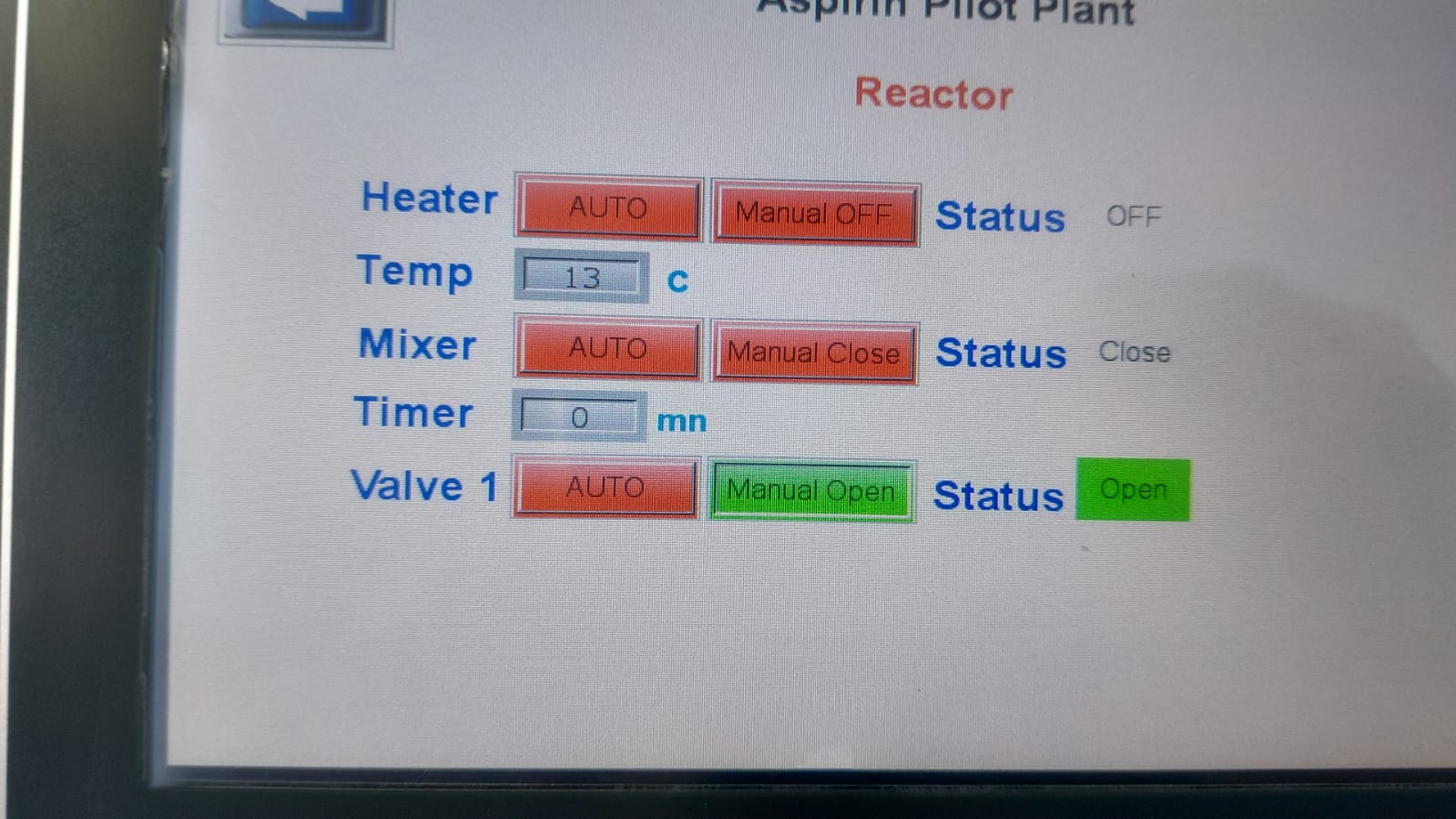

Open the valve V1 (tank1 : Reactor) |

Open the valve V1 to transfer the mixture from tank 1 (reactor) to tank 2 (cooler) (Reactor---->Reactor valve V1) |

The Water is transferred to Cooler (tank 2) |

|

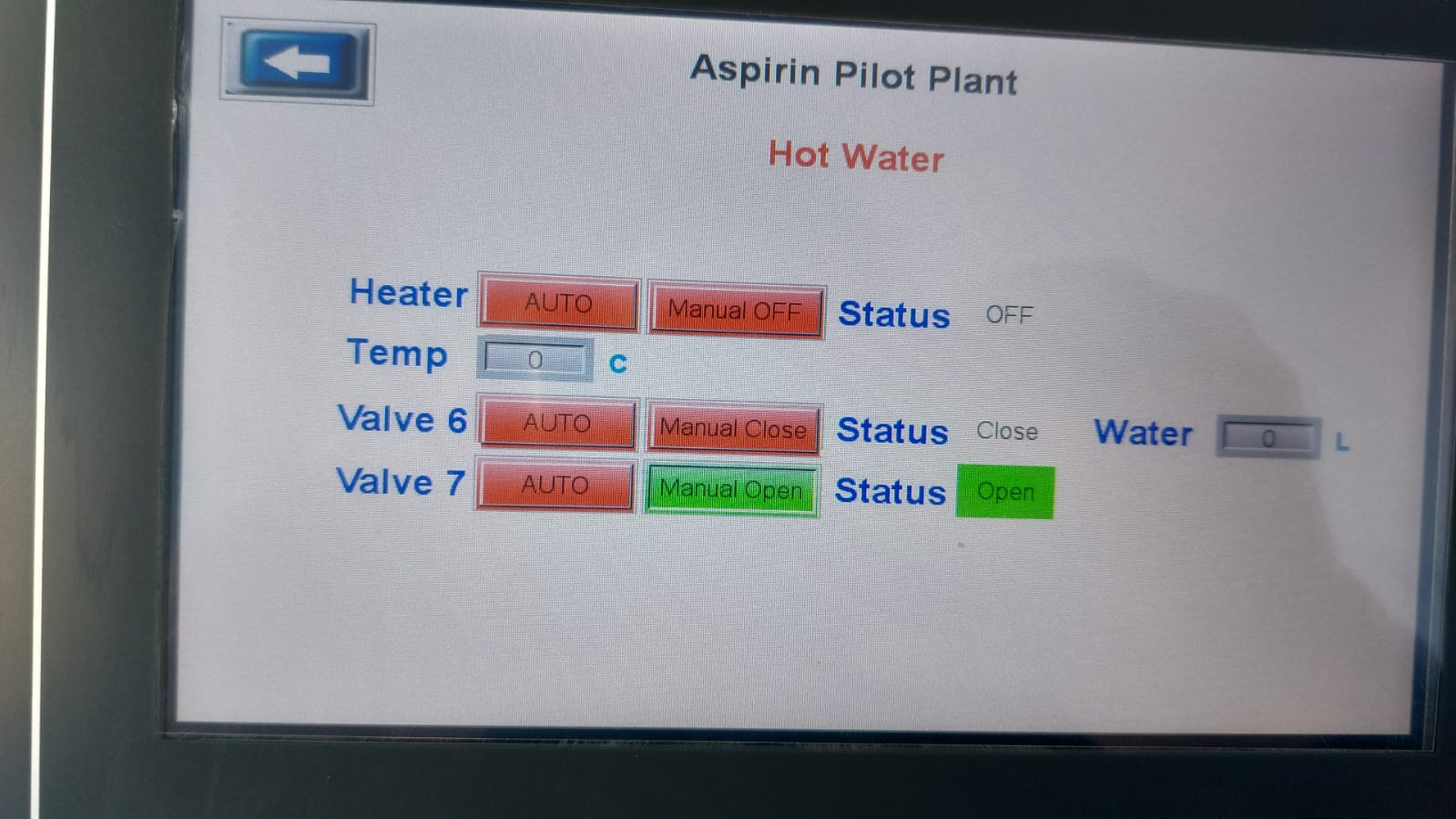

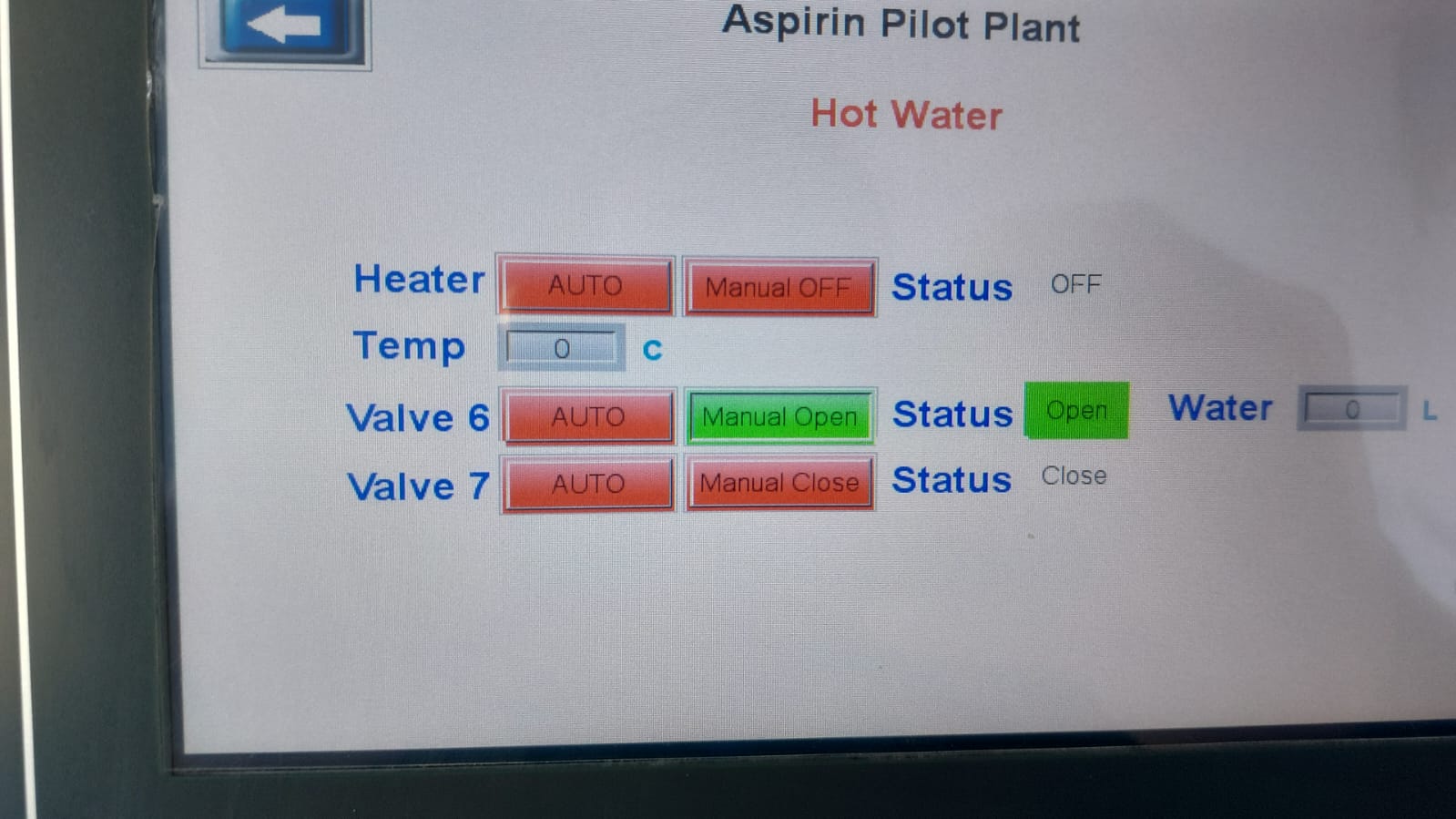

Open the valve 6 (tank 3 : HOT WATER) |

Open the valve V6 to add water from HOT WATER TANK (tank 3) to the cooler (tank 2) (HOt WATER TANK---->HOT WATER TANK valve V6) |

The water is in the cooler (tank 2) PS: -leak in pipes from tank 3 (Hot water) to tank 2 (Cooler) -the flow sensor not working |

|

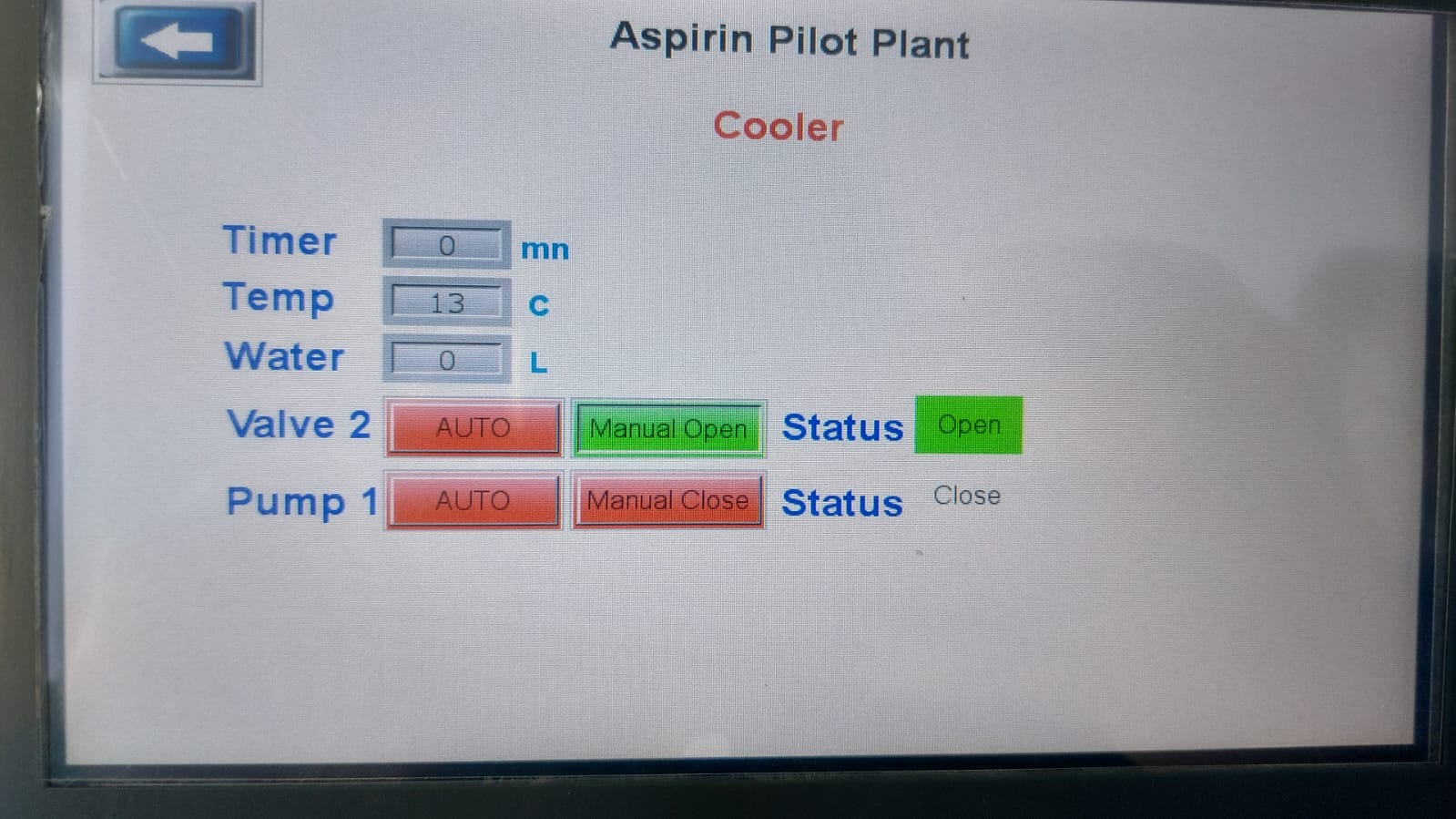

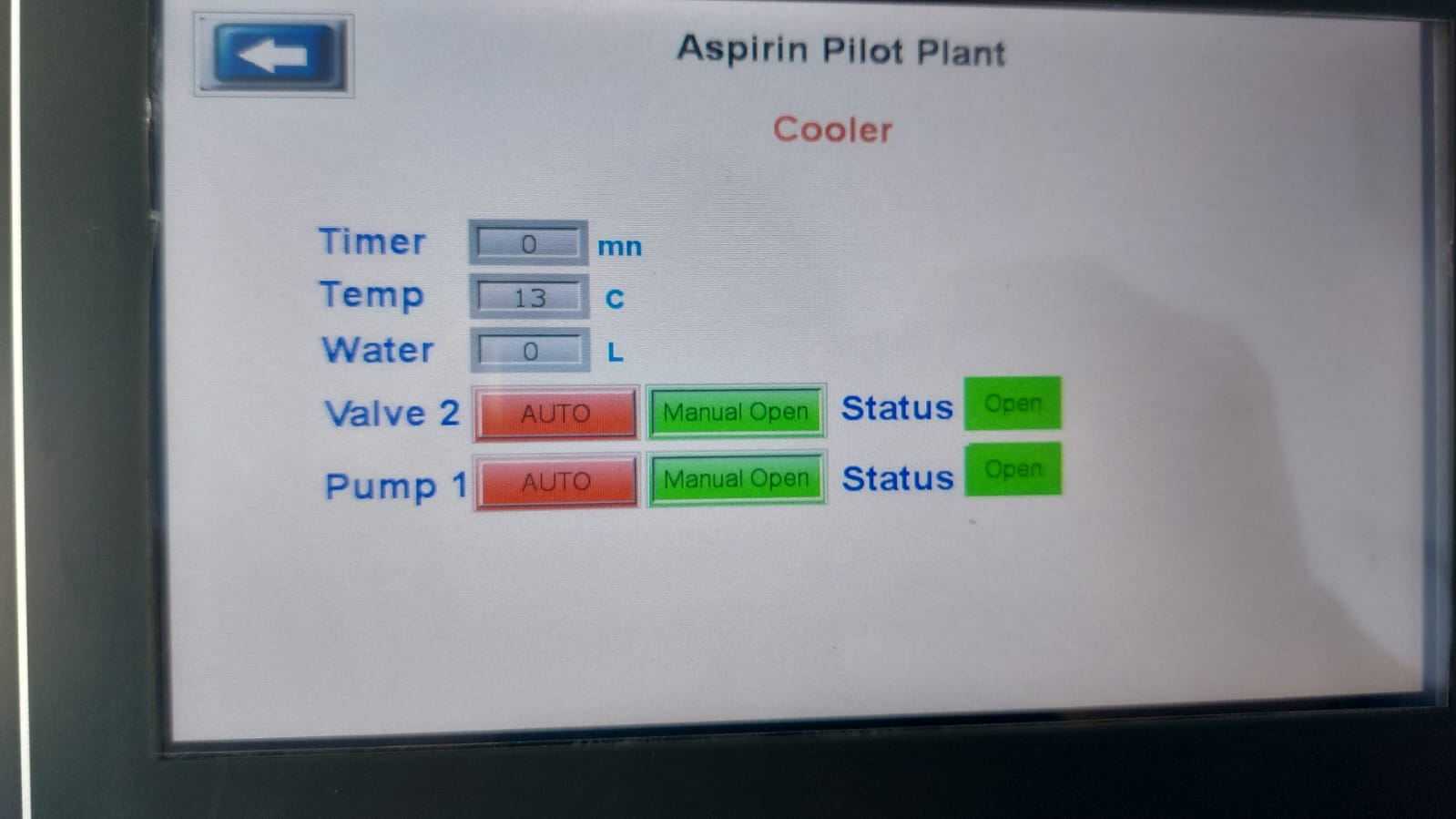

Open the valve V2 (tank 2: Cooler) |

Turn ON the pump 1 Open the valve V2 to transfer the Water from cooler (tank 2) to crystallizer (tank 4) (cooler---->cooler pump 1) (cooler---->cooler valve V2) |

The Water are transferred to the crystallizer (tank 4) PS: pump 1 stopped pumping |

|

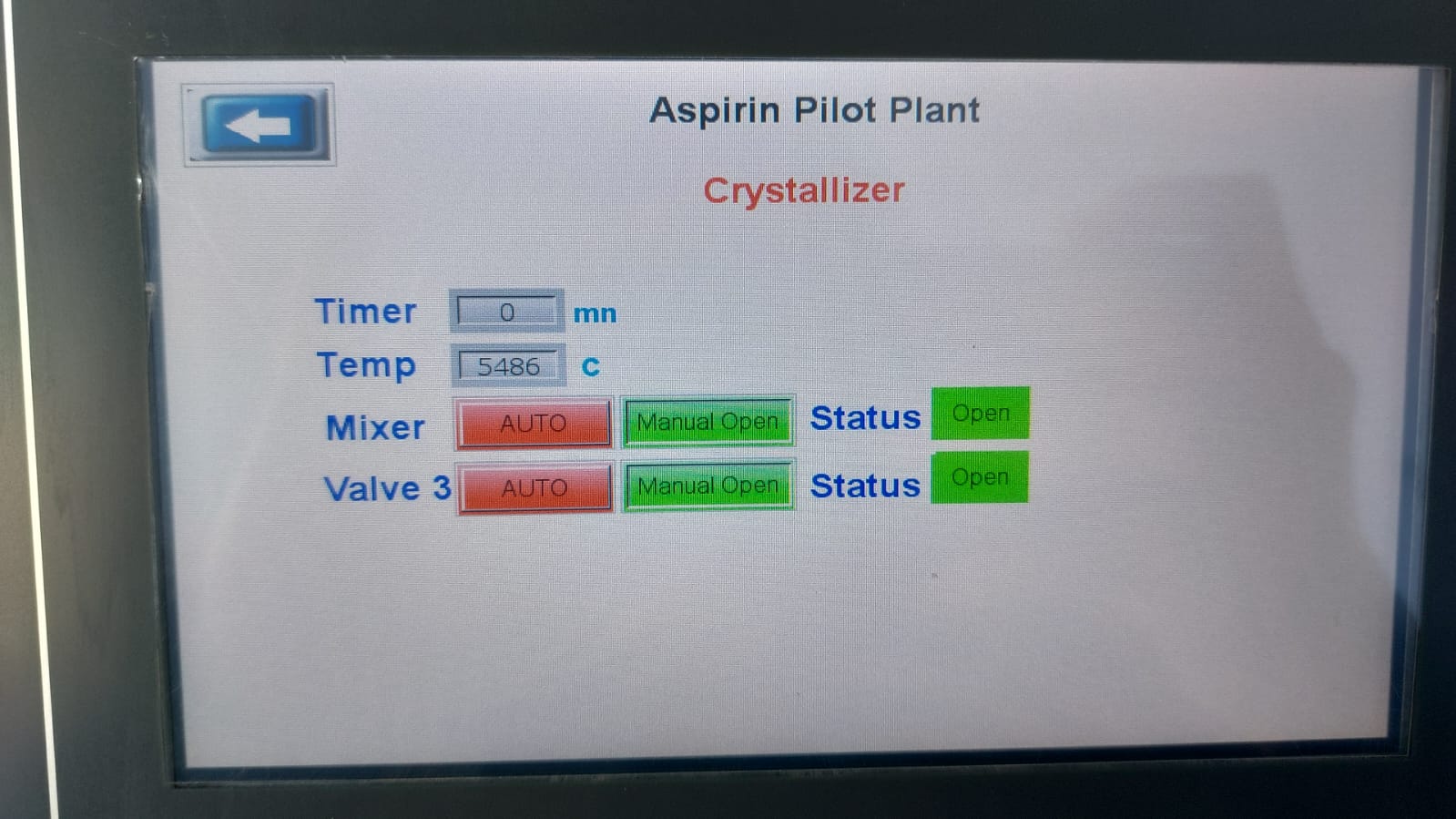

Switch on the mixer 2 (tank 4 : Crystallizer) |

Turn on the mixer from the control panel (Crystallizer--->Mixer ON) |

Mixer 2 is ON and start Mixing the Water Crystallizer (tank 4) |

|

Open the valve V3 (tank 4: Crystallizer) |

Open the valve V3 to transfer the Water from crystallizer (tank 4) to the filter (tank 5) (crystallizer---->crystallizer valve V3) |

The Water transferred to the filter (tank 5) |

|

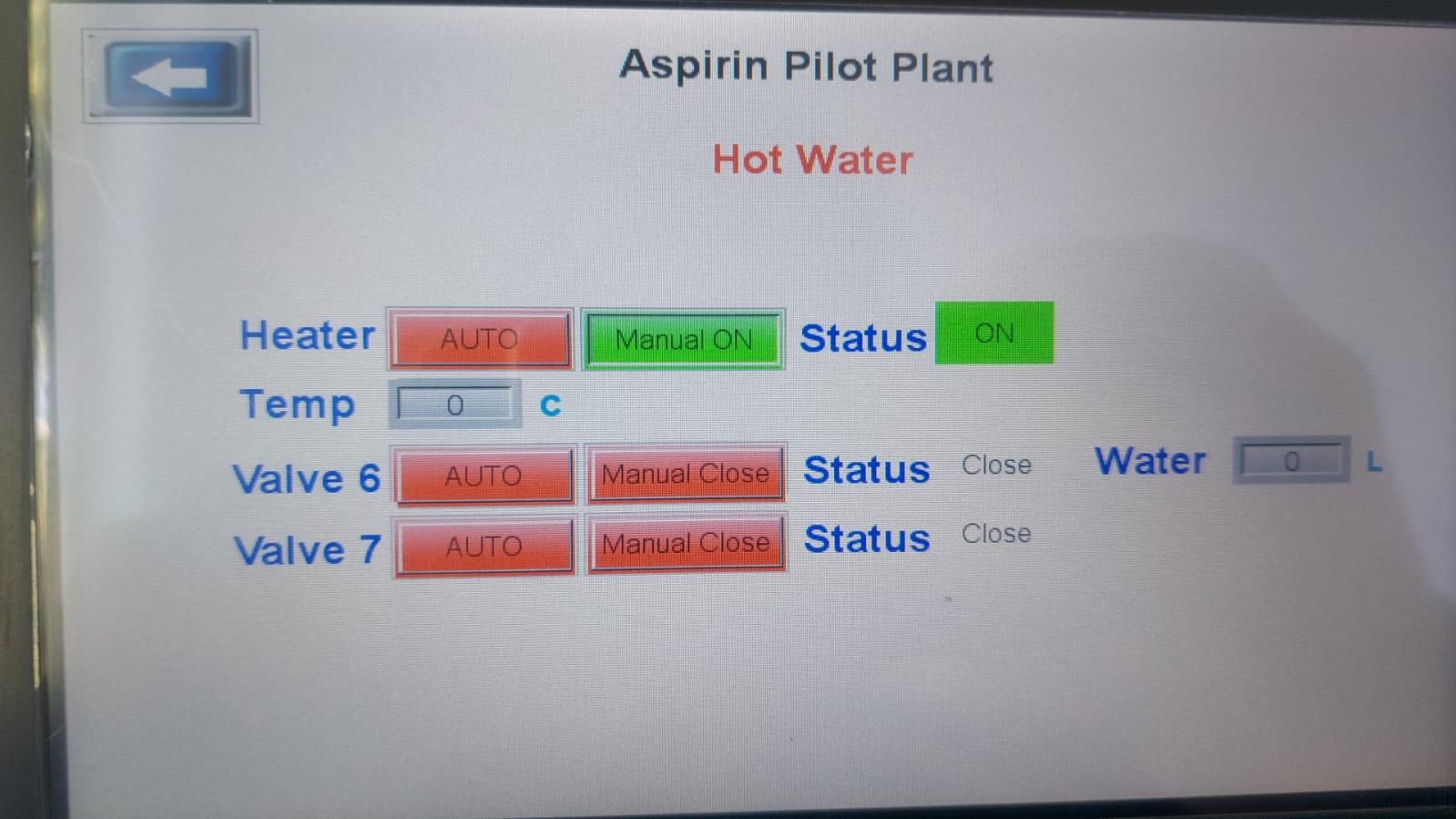

Open the valve V7 (TANK 3: HOT WATER) |

Open the valve V7 to add water from HOT WATER TANK (tank 3) to filter tank(tank 5) (HOT WATER TANK---->HOT WATER Valve V7) |

The Water transferred to filter tank (tank 5) |

|

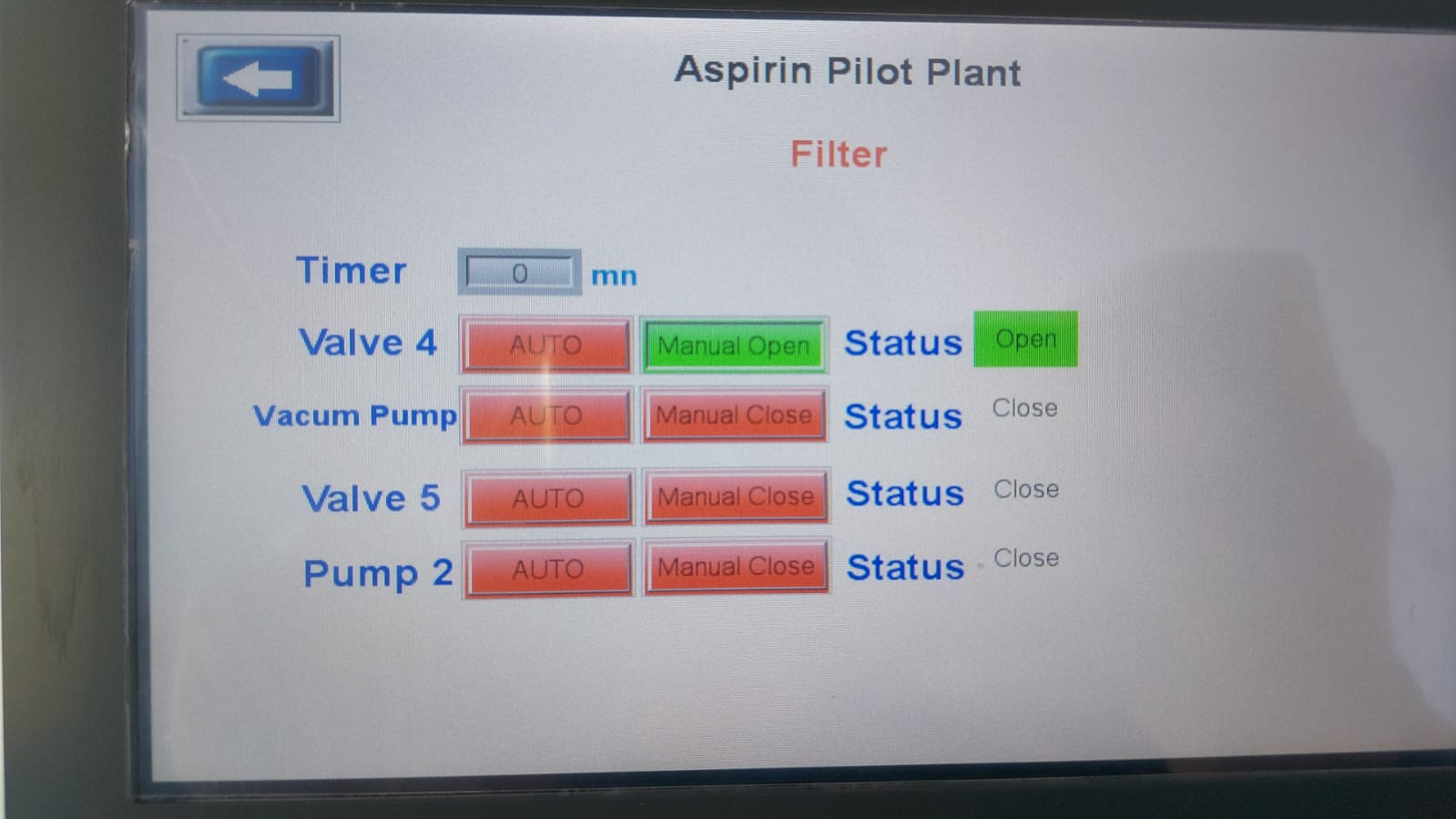

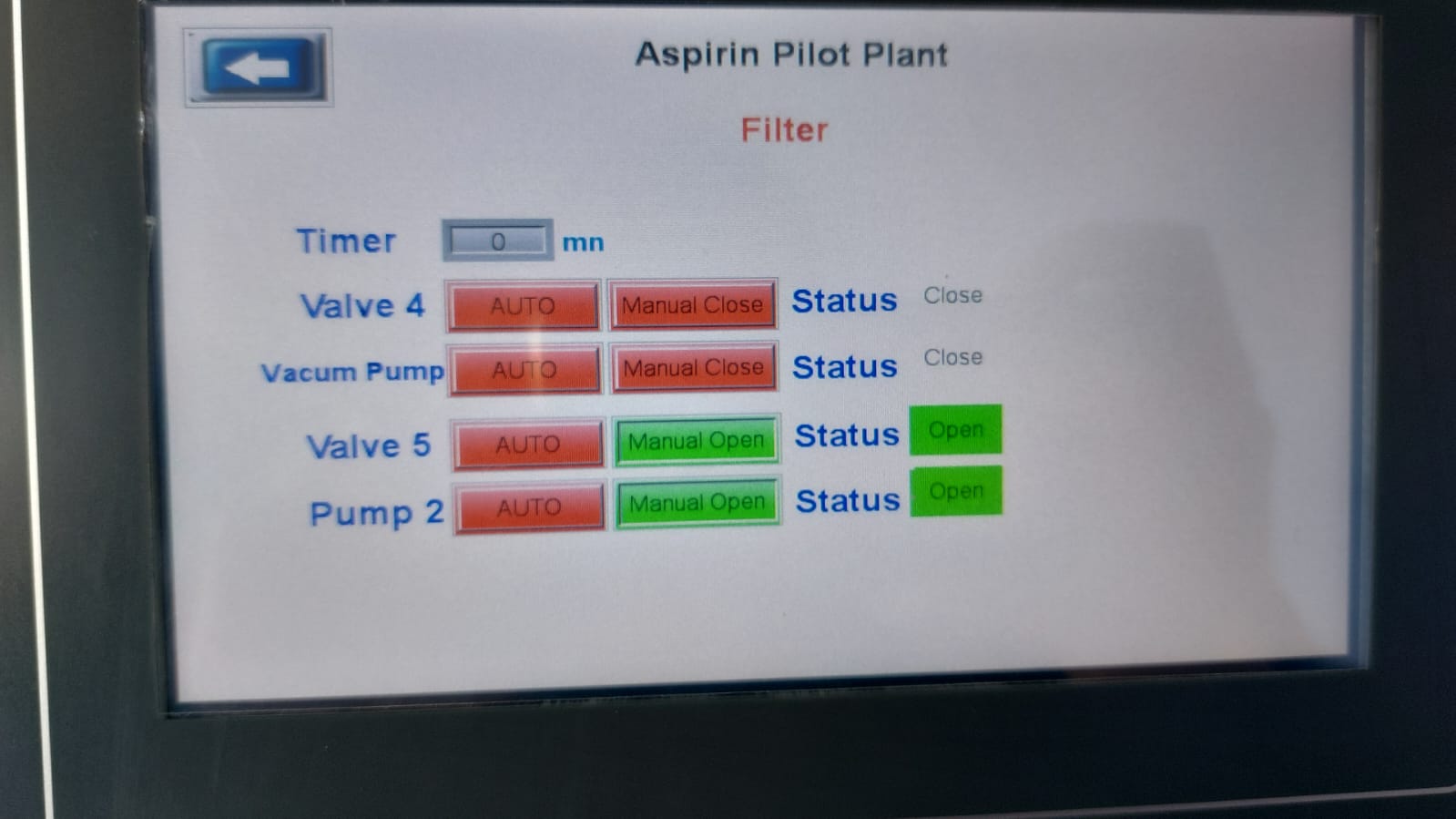

Open the valve V5 (tank 5: Filter) |

Turn ON the pump 2 Open the valve V5 The Water is pumped from tank 5 to tank 4 for the second crystallization (filter---->filter Valve V5) |

Water transferred to the crystallizer (tank 4) PS: pump 2 stopped pumping |

|

switching OFF the system |

switch OFF the system |

the system is OFF |

|

Postcondition |

system is OFF |

Overall Review: In this test we've noticed some leaks in some pipes, pumps stopping from pumping and 1 Temperature sensor need to reprogrammed

in the next test we will fix all those problems and try another test with water only.

Video003 (1): Testing Valves and mixers (water test 1) 28/11/2023

Video003 (2): Testing Valves and mixers and sensors (water test 2) 28/11/2023

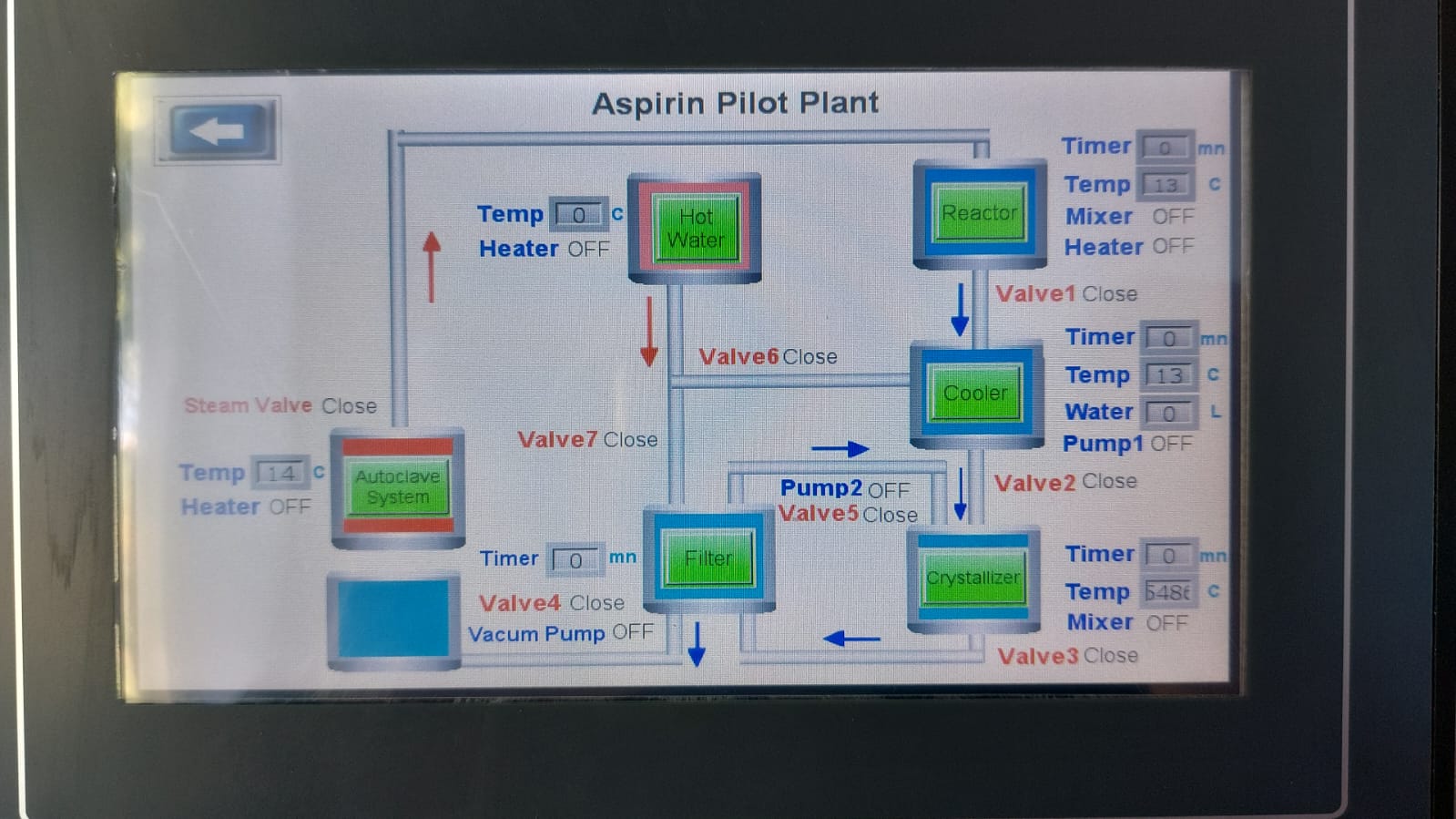

1. Overview of control panel system for Aspirin pilot plant

2. Turn ON the mixer by switching manually to mix the solution (PS: in this test we used water only)

3. Turn ON manually valve 1 to transfer the solution to the Cooler (tank 3)

4. Turn ON manually valve 7 to transfer distilled water from Hot water tank (tank 2) to filter (tank 5)

5. Turn ON manually valve 6 to transfer distilled water from Hot water tank (tank 2) to Cooler (tank 3) (PS: there's a flow sensor to determine the quantity needed of distilled water)

6. Turn ON manually the heater to warm up distilled water needed (PS: there's a temperature sensor to determine the temperature of DW required)

7. Turn ON manually valve 2 to transfer the mixture (Water) from the cooler (tank 3) to crystallizer (tank 4)

8. Turn ON manually pump 1 to transfer the mixture (Water) from the cooler (tank 3) to crystallizer (tank 4)

9. Turn ON munally the "Mixer" and valve 3 to mixing and transfer the mixture from the Crystallizer (tank 4) to the Filter ( tank 5)

10. Turn ON the valve 4 to transfer the mixture (water) from the Filter (tank 5) to Waste tank ( tank 6)

11. Turn ON valve 5 and pump 2 to transfer the mixture (water) from Filter (tank 5) to crystallizer (tank 4) to recrystallization (PURIFICATION STEP)