- Hits: 1486

004: Aspirin Production System Test (Water test)

|

Step |

Step Description |

Results |

|

Precondition |

System is OFF |

|

|

TURNING ON the system |

Turn ON the control panel

|

The system is ON |

|

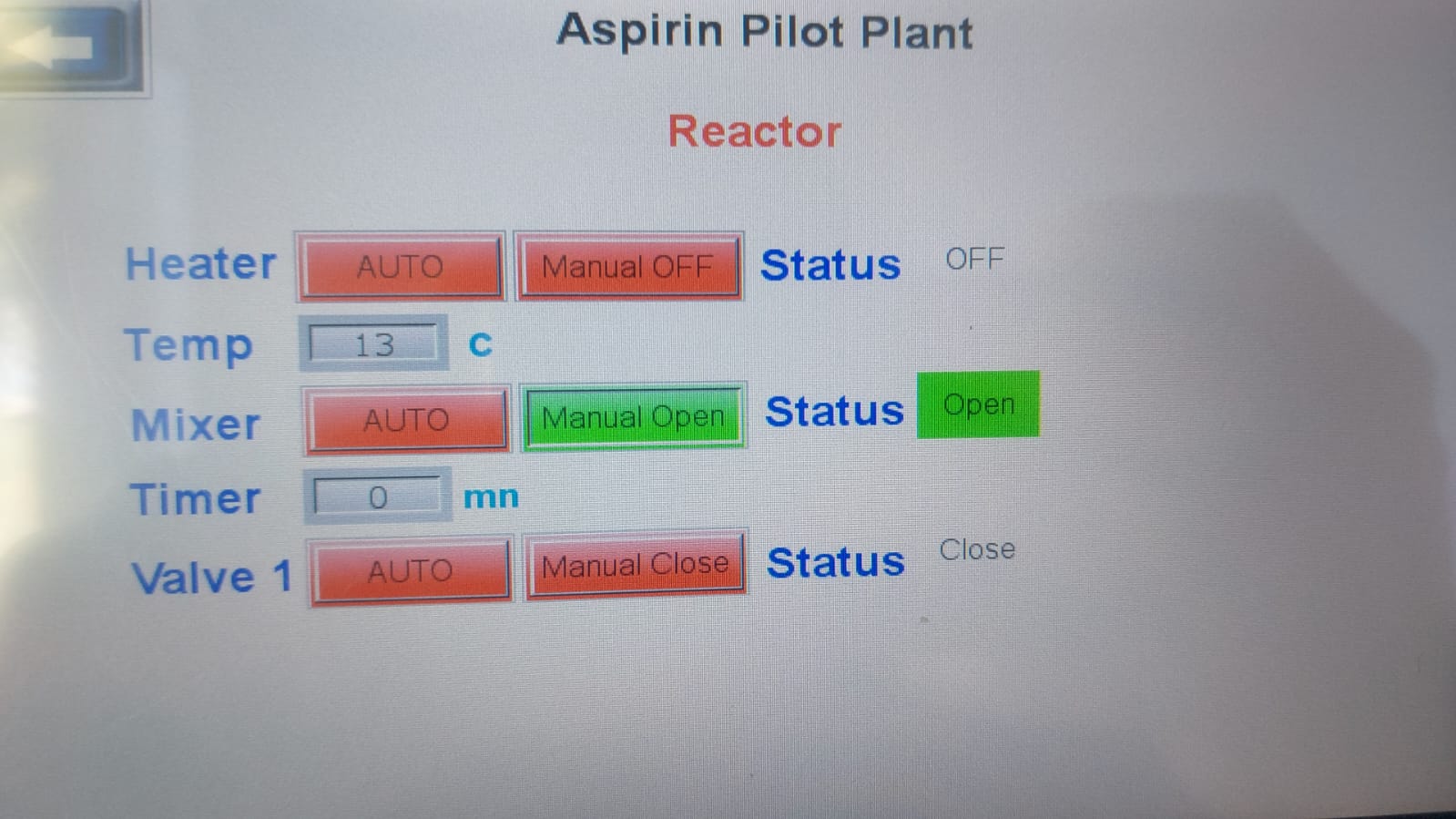

Switch on the mixer 1 (tank 1 : Reactor) |

Turn on the mixer 1 from the control panel (Reactor--->Mixer ON) |

Mixer 1 is ON and start Mixing the Water (Reactor) |

|

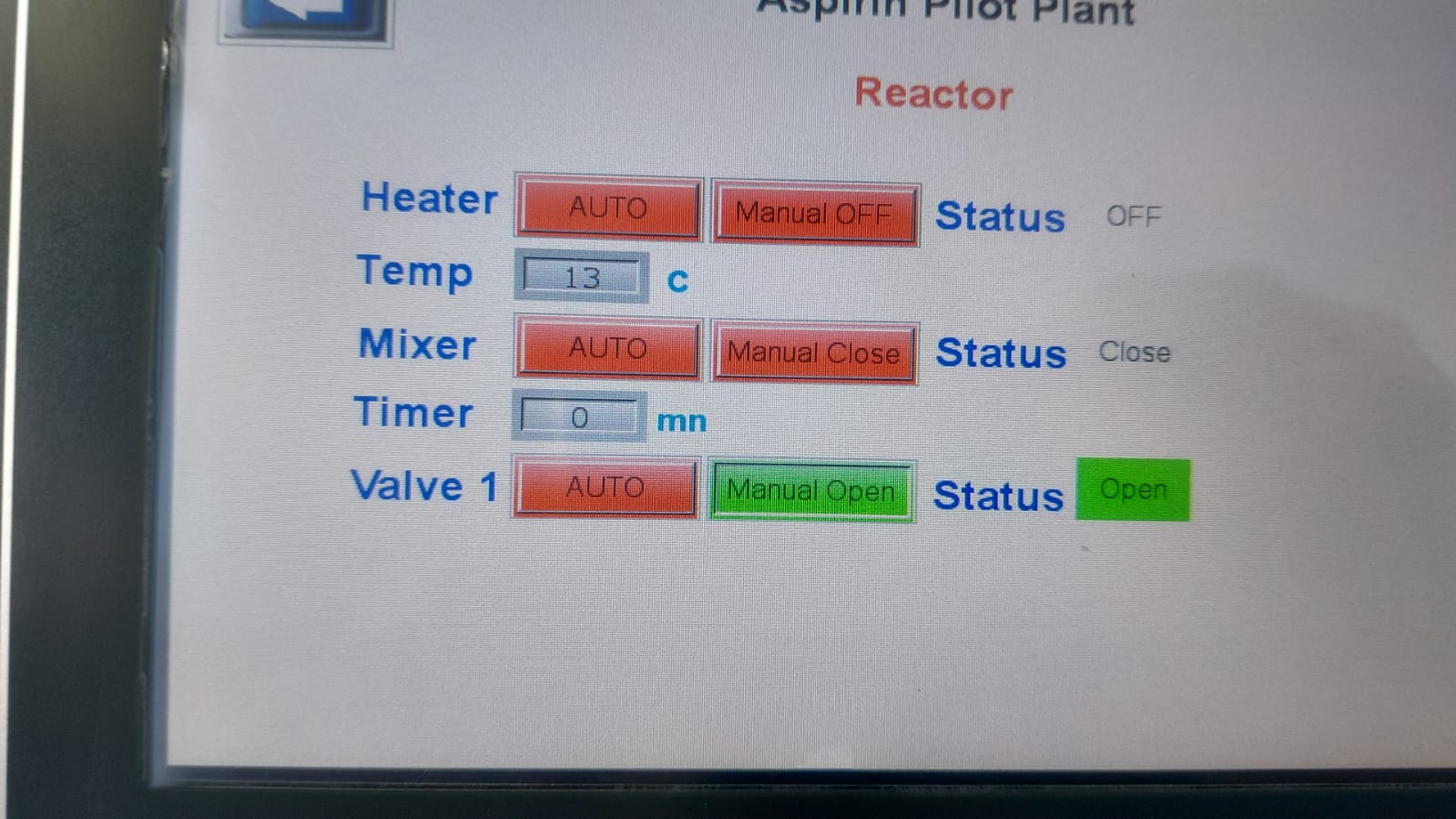

Open the valve V1 (tank1 : Reactor) |

Open the valve V1 to transfer the mixture from tank 1 (reactor) to tank 2 (cooler) (Reactor---->Reactor valve V1) |

The Water is transferred to Cooler (tank 2) |

|

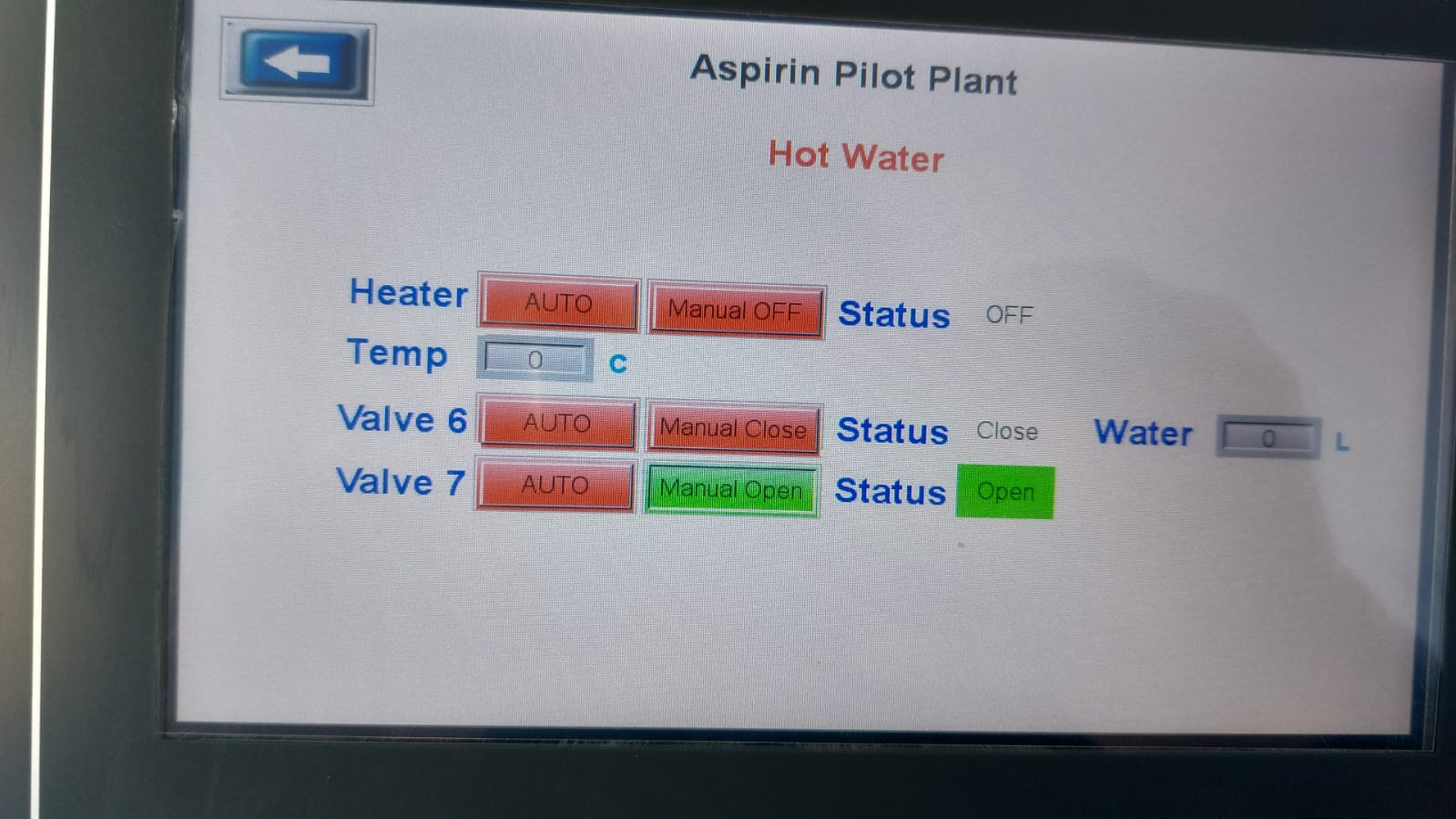

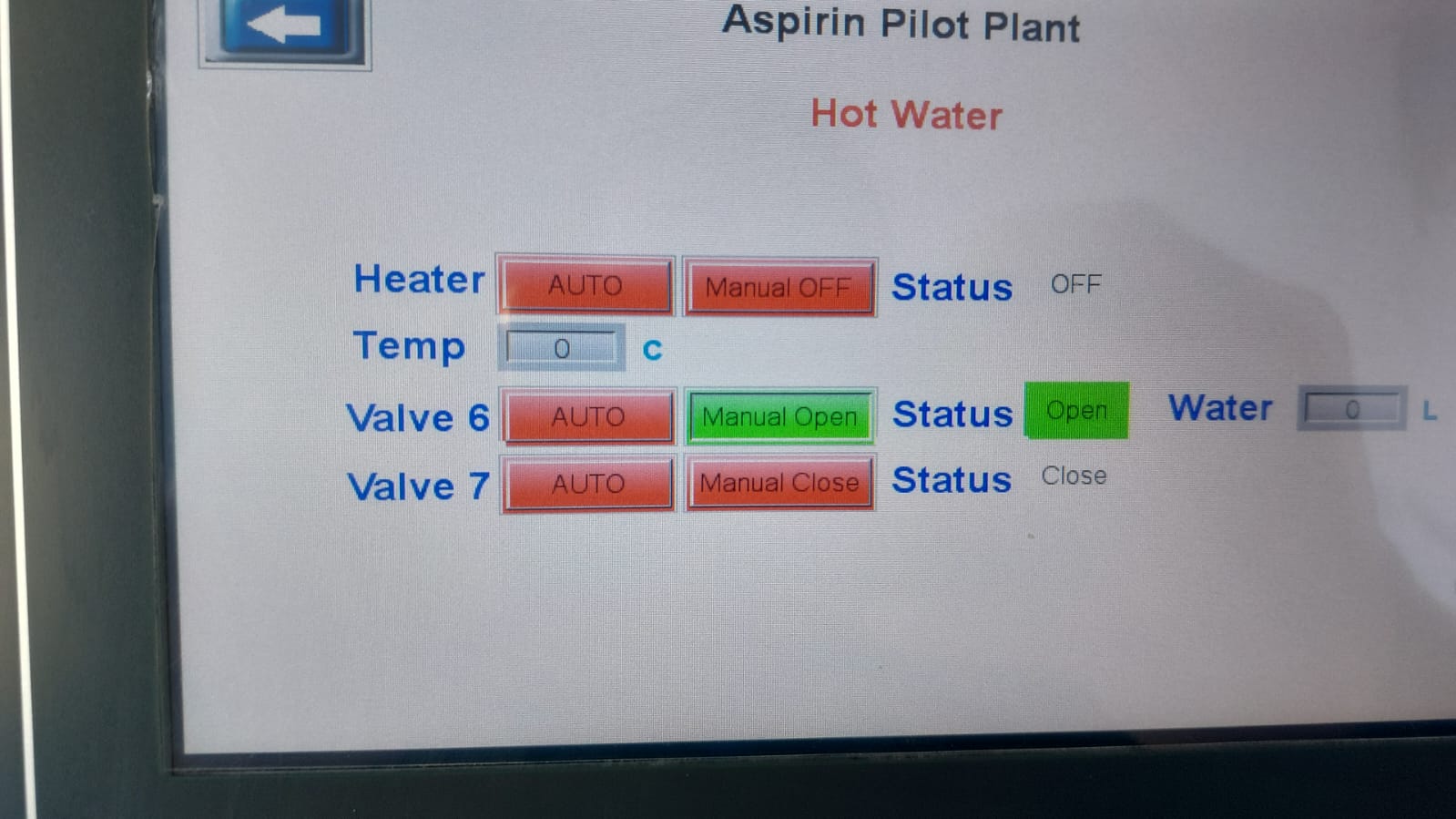

Open the valve 6 (tank 3 : HOT WATER) |

Open the valve V6 to add water from HOT WATER TANK (tank 3) to the cooler (tank 2) (HOt WATER TANK---->HOT WATER TANK valve V6) |

-The water is in the cooler (tank 2)

-the flow sensor not working |

|

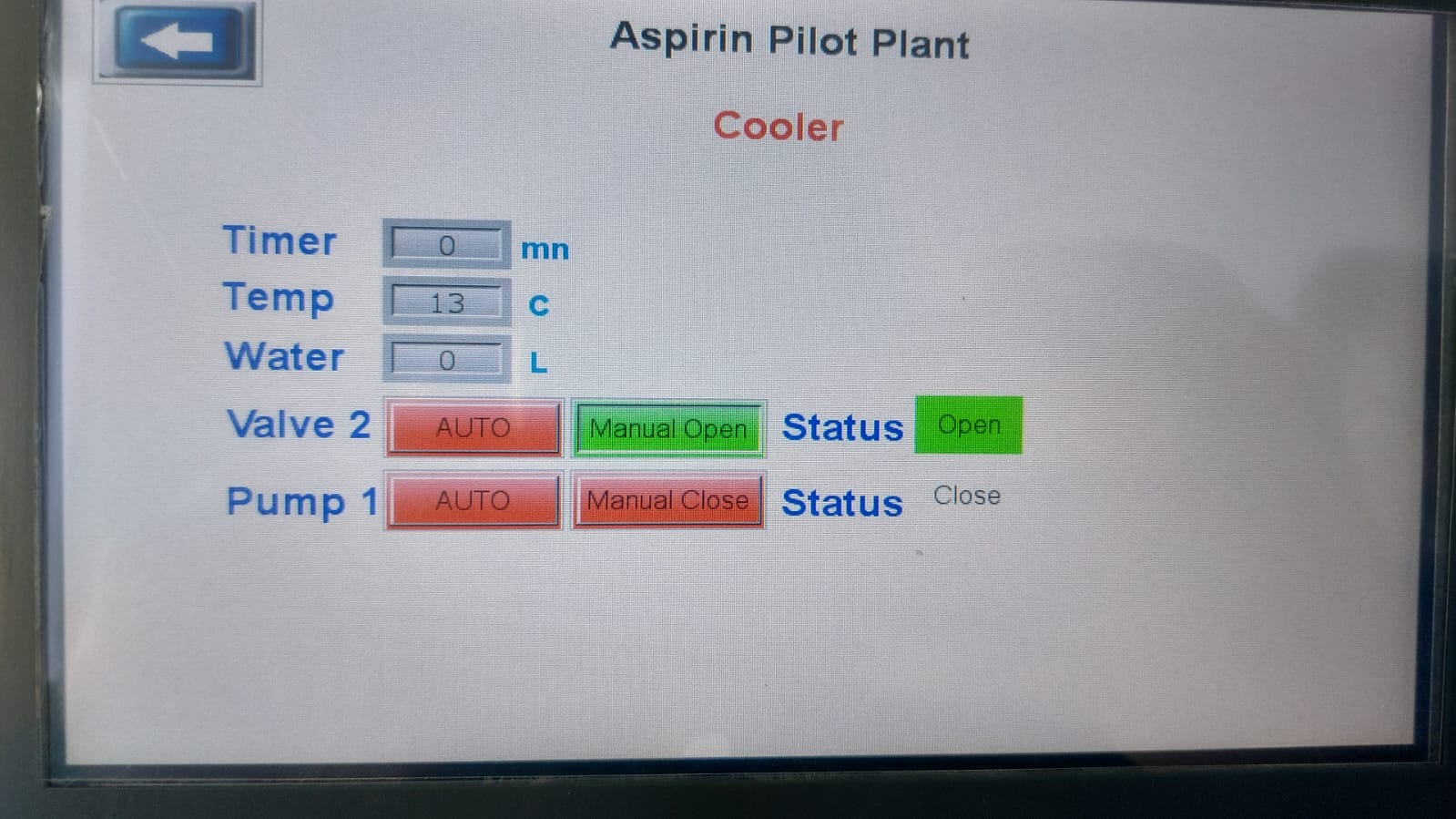

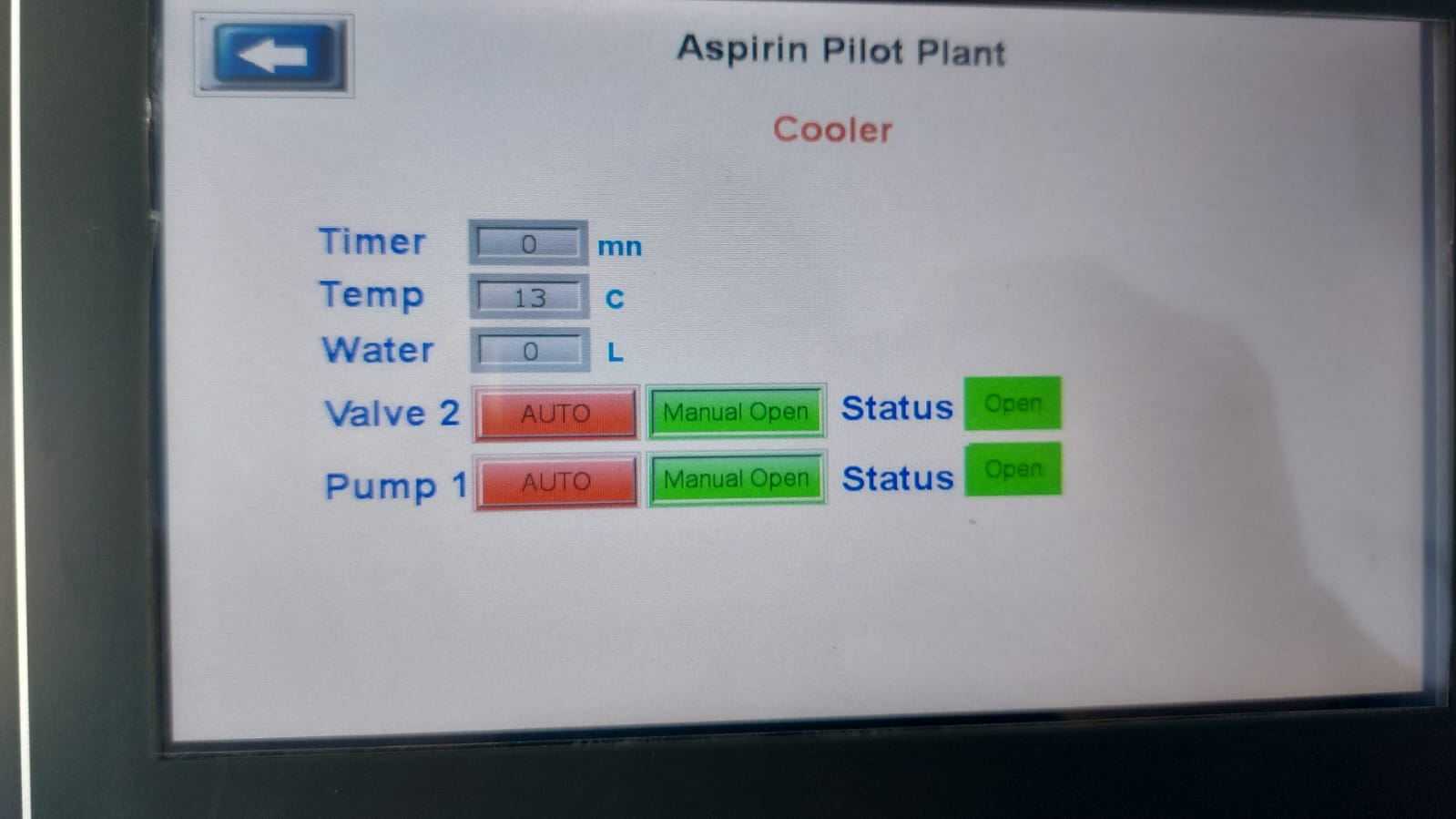

Open the valve V2 (tank 2: Cooler) |

Turn ON the pump 1 Open the valve V2 to transfer the Water from cooler (tank 2) to crystallizer (tank 4) (cooler---->cooler pump 1) (cooler---->cooler valve V2) |

The Water are transferred to the crystallizer (tank 4) PS: pump 1 stopped pumping |

|

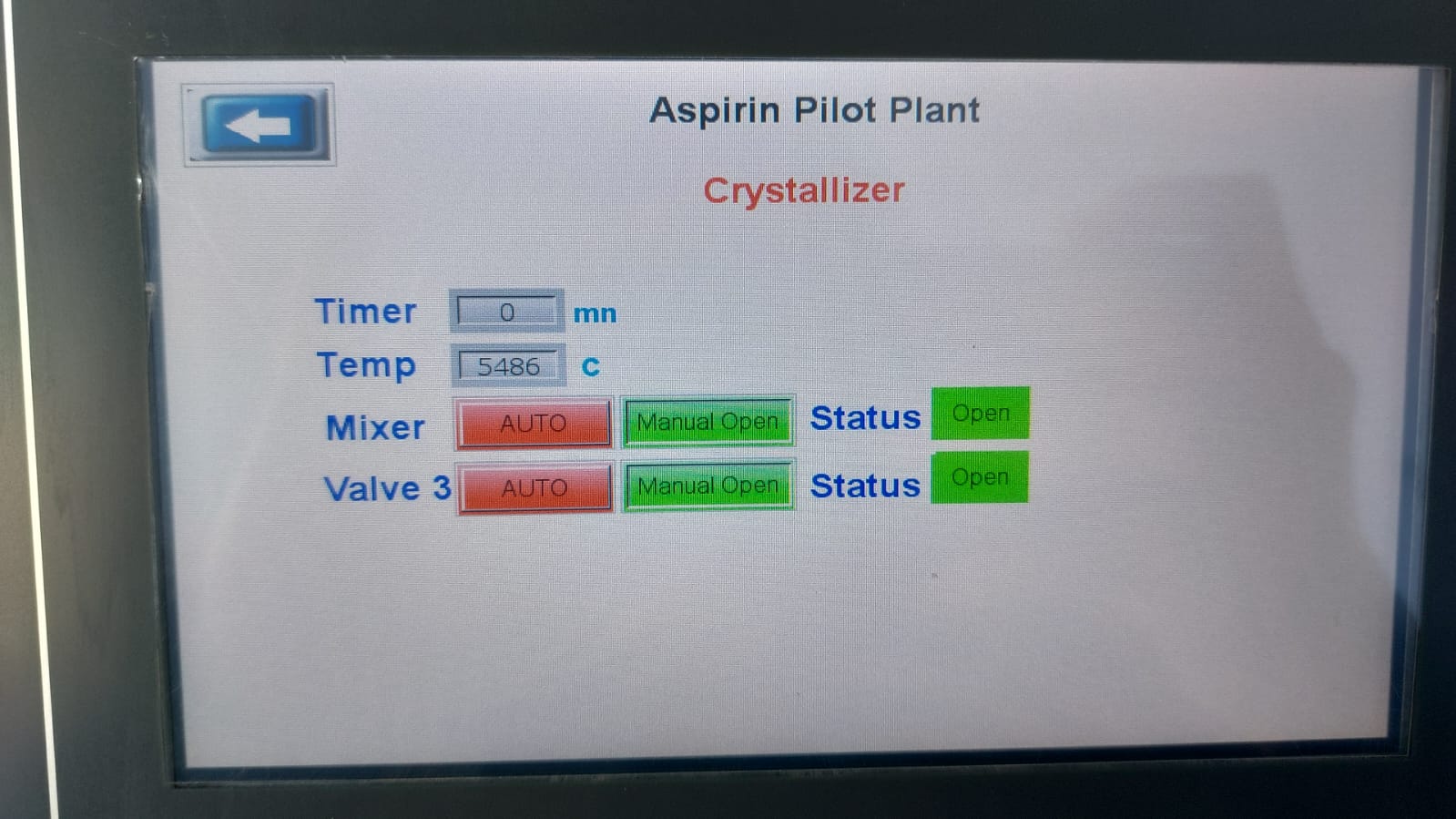

Switch on the mixer 2 (tank 4 : Crystallizer) |

Turn on the mixer from the control panel (Crystallizer--->Mixer ON) |

Mixer 2 is ON and start Mixing the Water Crystallizer (tank 4) |

|

Open the valve V3 (tank 4: Crystallizer) |

Open the valve V3 to transfer the Water from crystallizer (tank 4) to the filter (tank 5) (crystallizer---->crystallizer valve V3) |

The Water transferred to the filter (tank 5) |

|

Open the valve V7 (TANK 3: HOT WATER) |

Open the valve V7 to add water from HOT WATER TANK (tank 3) to filter tank(tank 5) (HOT WATER TANK---->HOT WATER Valve V7) |

The Water transferred to filter tank (tank 5) |

|

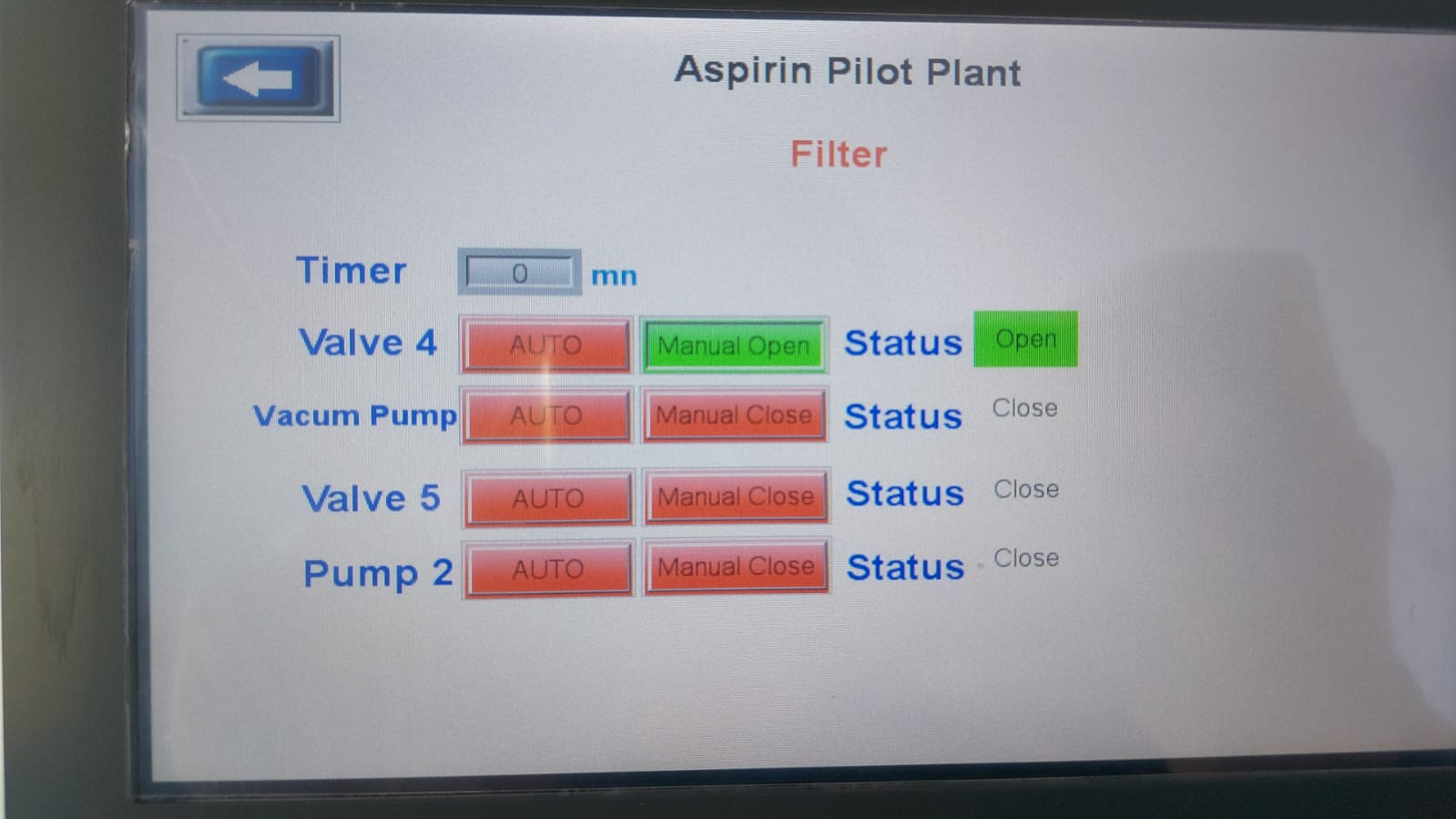

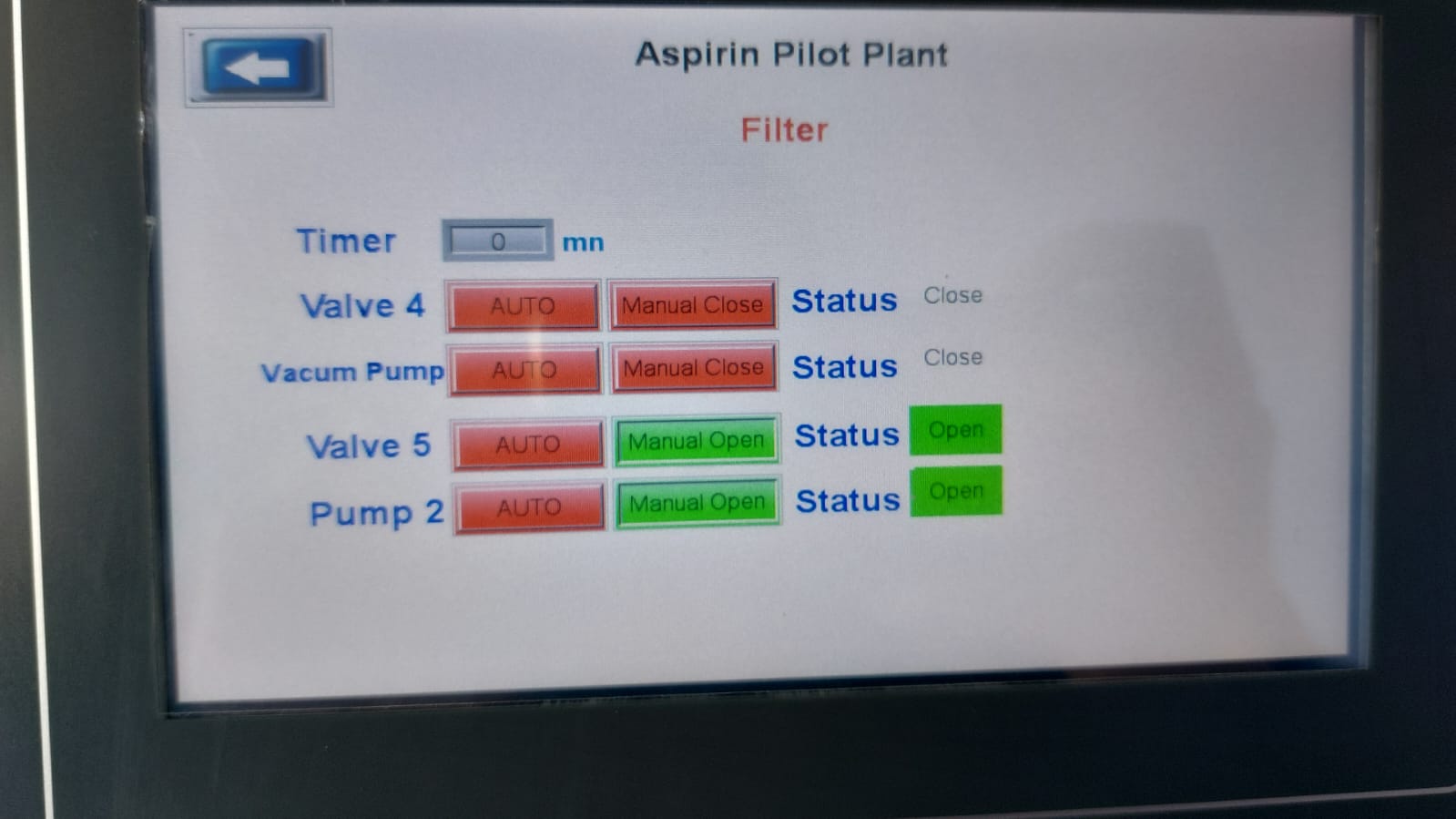

Open the valve V5 (tank 5: Filter) |

Turn ON the pump 2 Open the valve V5 The Water is pumped from tank 5 to tank 4 for the second crystallization (filter---->filter Valve V5) |

Water transferred to the crystallizer (tank 4) PS: pump 2 stopped pumping |

|

switching OFF the system |

switch OFF the system |

the system is OFF |

|

Postcondition |

system is OFF |

Overall Review: In this test we've noticed leak in HOT WATER TANK, pumps stopping from pumping (fixed confirmed), Temperature sensor breaked need to release the pressure from the sensor and we need to make a vent for air pressure in tank 3 (Cooler).

in the next test we will fix all those problems and try another test with water only.

Video004: Testing Valves, mixers and pumps (water test 3) 1/12/2023

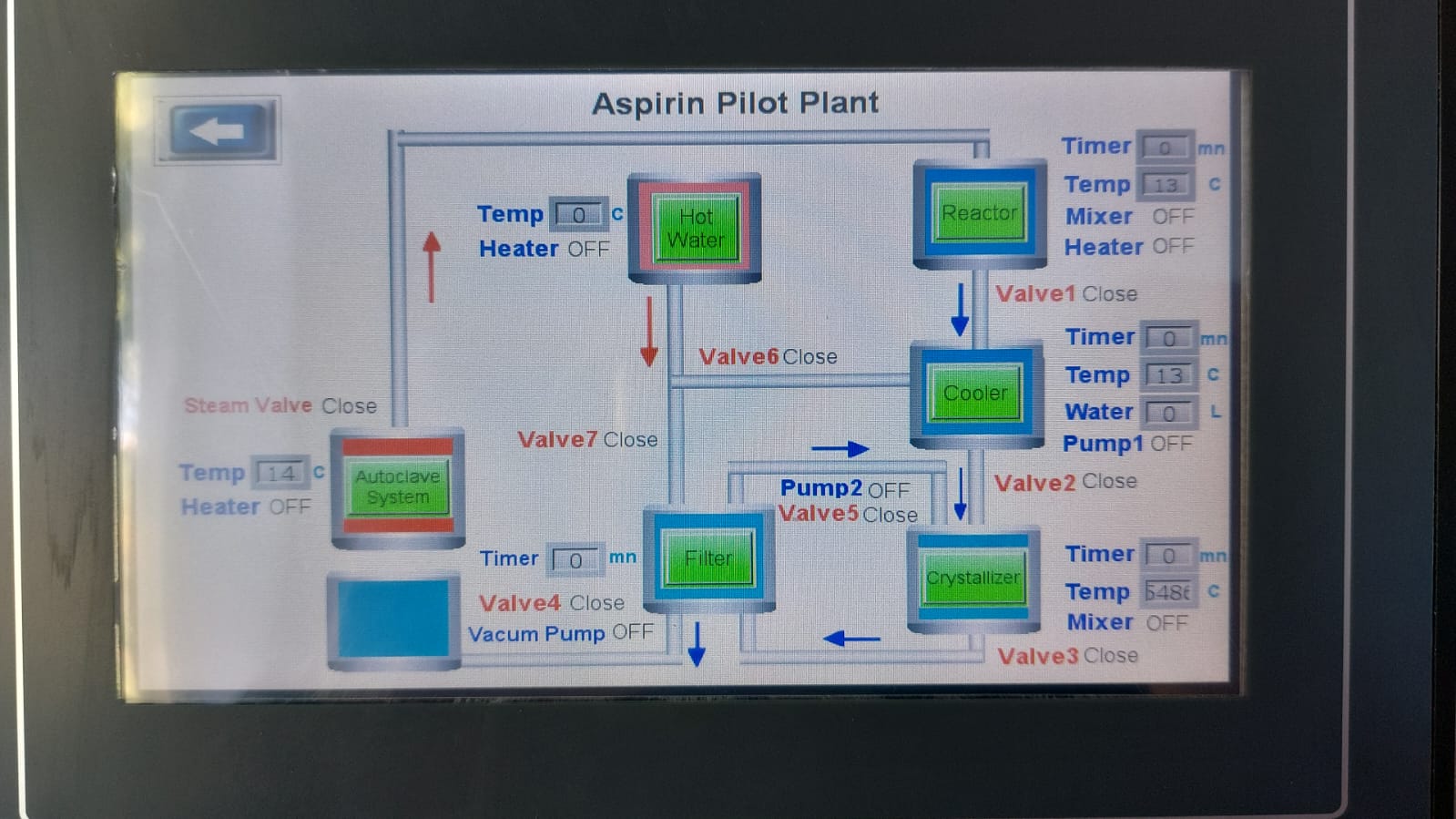

1. Overview of control panel system for Aspirin pilot plant

2. Turn ON the mixer by switching manually to mix the solution (PS: in this test we used water only)

3. Turn ON manually valve 1 to transfer the solution to the Cooler (tank 3)

4. Turn ON manually valve 7 to transfer distilled water from Hot water tank (tank 2) to filter (tank 5)

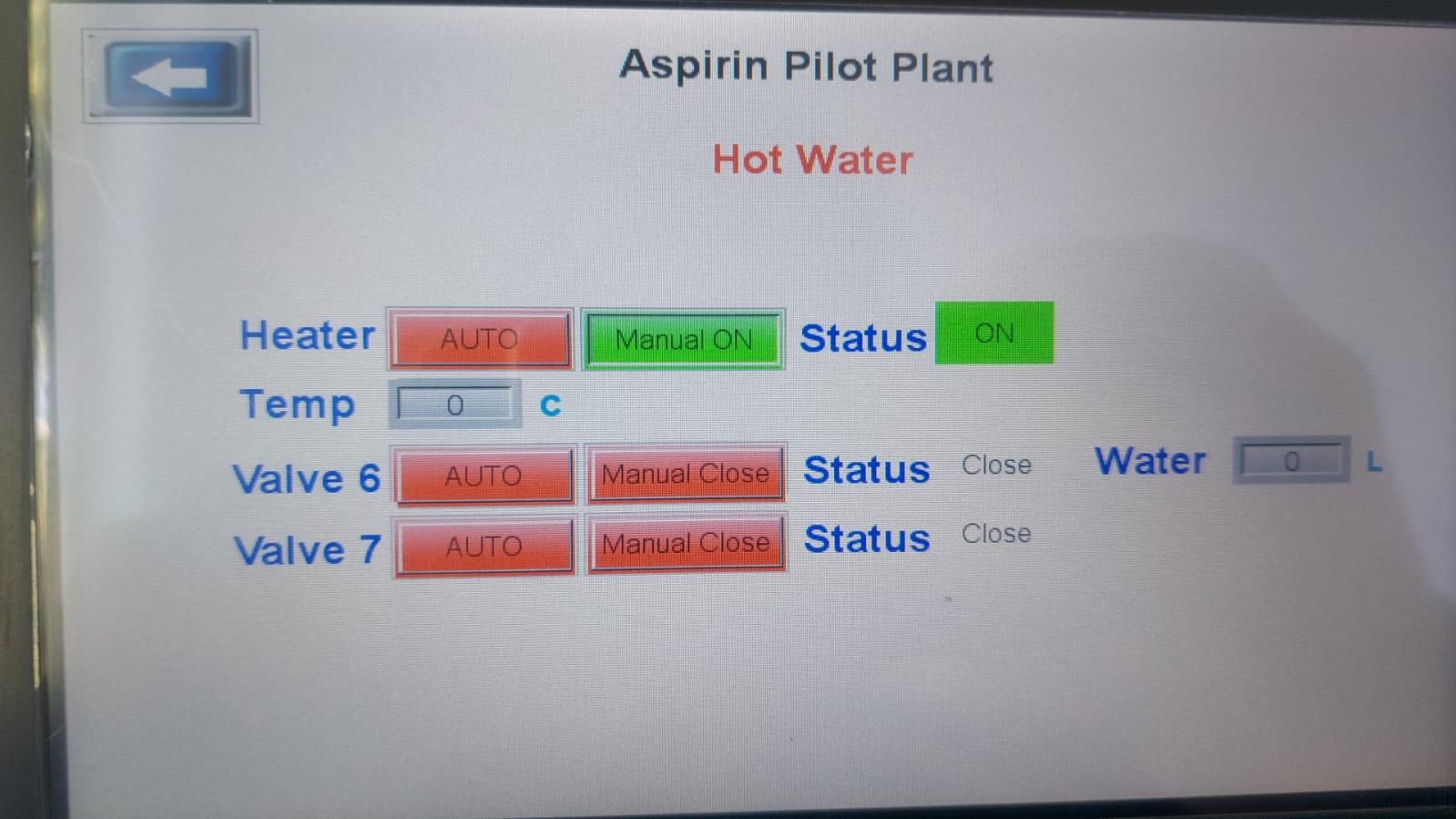

5. Turn ON manually valve 6 to transfer distilled water from Hot water tank (tank 2) to Cooler (tank 3) (PS: there's a flow sensor to determine the quantity needed of distilled water)

6. Turn ON manually the heater to warm up distilled water needed (PS: there's a temperature sensor to determine the temperature of DW required)

7. Turn ON manually valve 2 to transfer the mixture (Water) from the cooler (tank 3) to crystallizer (tank 4)

8. Turn ON manually pump 1 to transfer the mixture (Water) from the cooler (tank 3) to crystallizer (tank 4)

9. Turn ON munally the "Mixer" and valve 3 to mixing and transfer the mixture from the Crystallizer (tank 4) to the Filter ( tank 5)

10. Turn ON the valve 4 to transfer the mixture (water) from the Filter (tank 5) to Waste tank ( tank 6)

11. Turn ON valve 5 and pump 2 to transfer the mixture (water) from Filter (tank 5) to crystallizer (tank 4) to recrystallization (PURIFICATION STEP)