- Hits: 2358

Biogas production from municipal waste

From Biogas Plant Development Handbook | BiogasWorld:

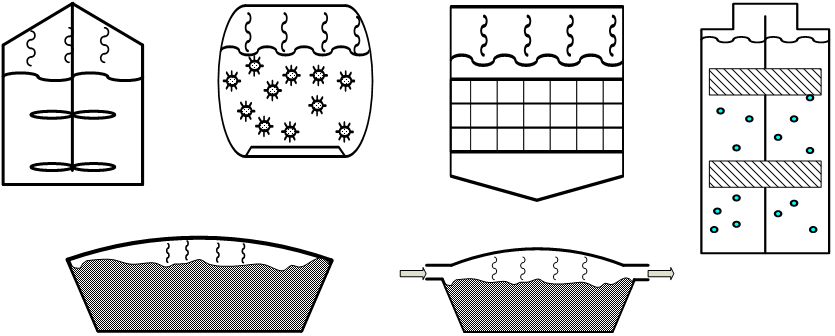

WET DIGESTION

The process is considered wet digestion when the content of the digester is pumpable. That means that the material inside the digester has a consistency of approximately 10% dry matter or less (90% water).

There exist many configurations of wet digesters:

- Complete mix or Completely stirred tank reactor (CSTR)

- Plug-flow

- Upflow Anaerobic Sludge Blanket (UASB)

- Fixed film reactor

- Floating films reactors

- Sludge bed reactors

- And more.

These configurations have been designed to optimize the process for various feedstock conditions and market applications.

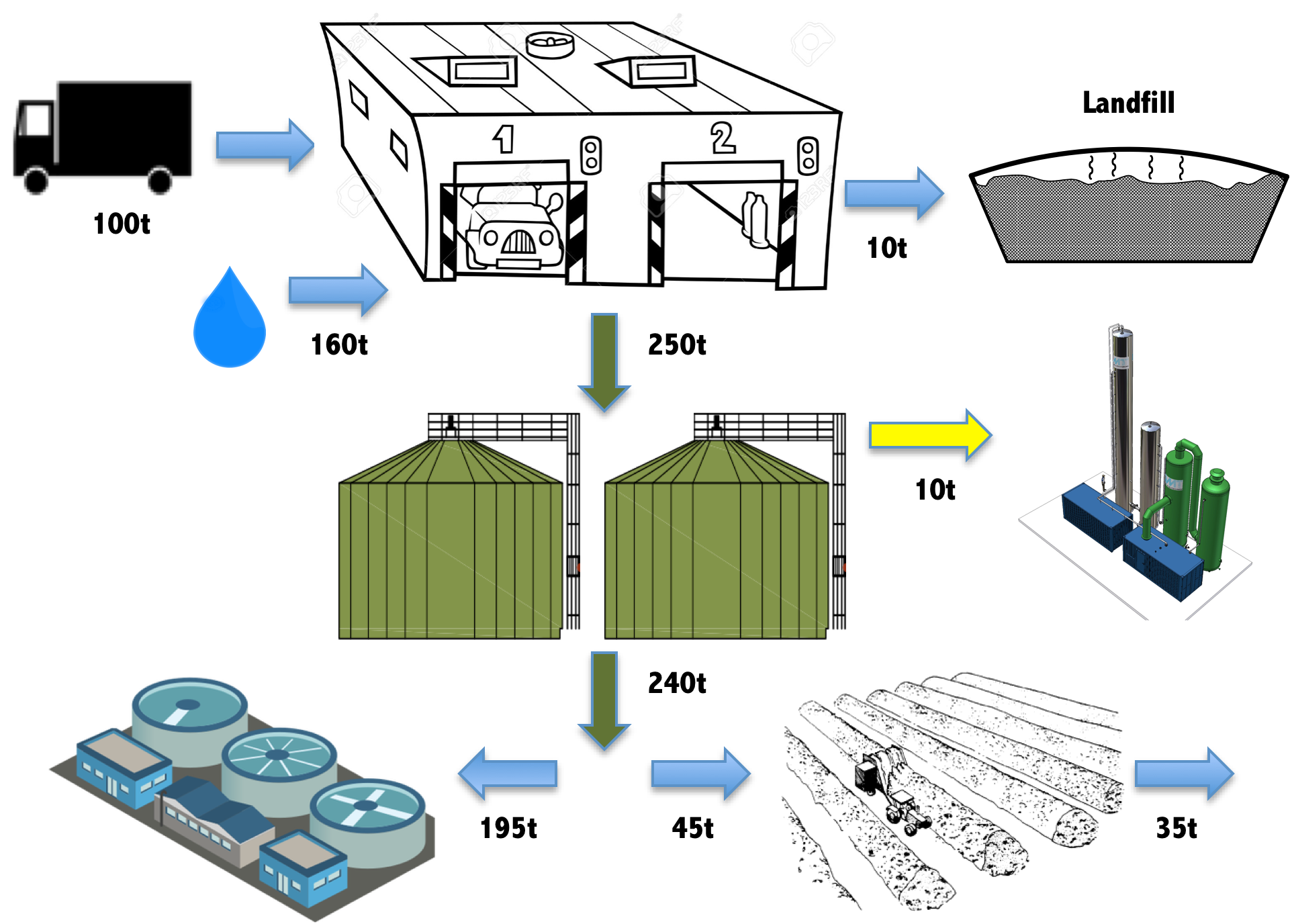

The mass balance of a typical wet digestion process looks like this:

For example, 100 tonnes of solid municipal residential source separated organics (SSO) arrives at the biogas plant using wet digestion (complete mix). This feedstock needs to be pretreated to remove potential contaminants (plastics, metal, sands, etc.). Approximately 10 tonnes will be removed as contaminants and will probably be landfilled.

In order to be pumpable (10% TS), the feedstock will be diluted with water that may come from a fresh source or from a mixed of fresh and recycled water from the wastewater portion of the biogas plant. The liquid feedstock going to the digester will be approximately 250 tonnes.

In the digesters, the bacteria will consume the majority of the volatile solids in the feedstock and will convert them into biogas. Approximately 10 tonnes of gas will come out of the digesters. The more liquid digestate will represent approximately 240 tonnes.

At this point, the digestate may be applied to land directly. Please note that 100 tonnes of solid material turned into 240 tonnes of liquid and land applying the digestate in this form will present significant transportation costs.

The digestate may also be separated into a solid fraction (45 tonnes) to be land applied (or composted down to 35 tonnes) and a liquid fraction (195 tonnes) to be returned the sanitary sewage or directly back to nature.

One may be tempted to use the treated wastewater as dilution water for the input feedstock and limit the amount of water consumed and rejected by the process. It is possible only if the wastewater plant removes almost all nutrients (salts and ammonia/ammonium) in the water. Without this removal, there will be a rapid build up of nutrients in the water and this will inhibit and/or kill the anaerobic digestion process.

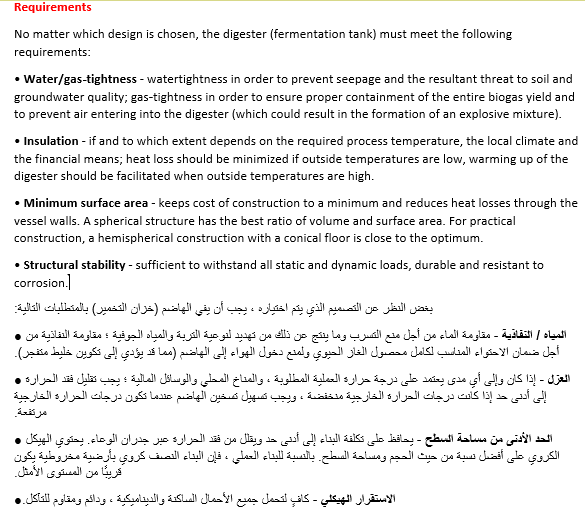

يجب أن يفي الهاضم بالمتطلبات التالية:

يجب مراعاة الجوانب التالية فيما يتعلق بالتصميم والتشغيل:

Bismillah