VaEf Airship

project "alternative Lotte": Project Report (August 2000 July 2006)

Development

of a Flight Control System for a airship for measuring wind data

Based on student research works of

Samir Mourad, Sven Forstmann, Jamal E., Muhammad

Subhan, Rabih al-Farkh, Nasih Abdelhaqq, Yaser Mikou, Abdelfattah Ammar

Project Manager: Samir Mourad,

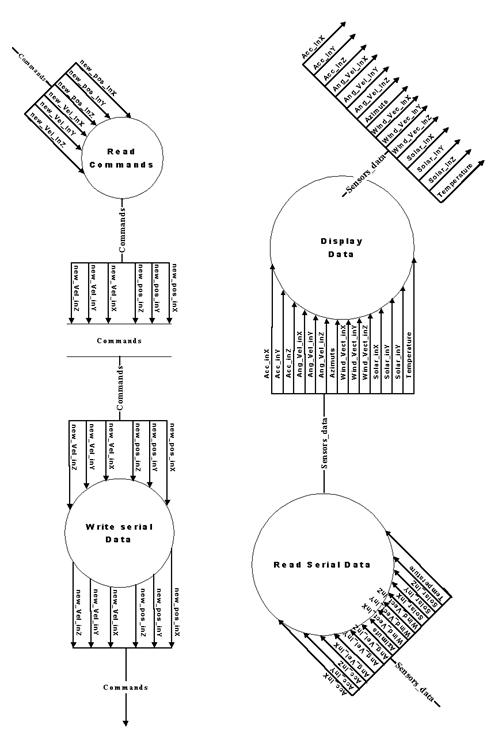

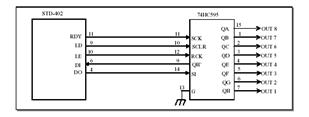

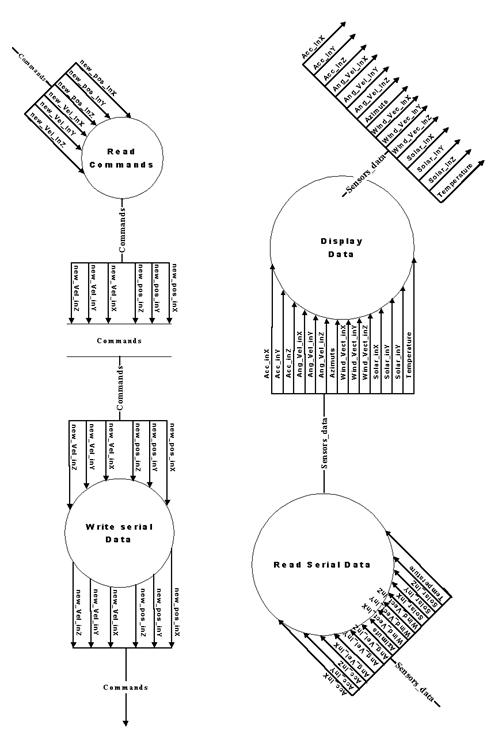

Dipl.-Ing. Dipl.-Inform. (MS Sc.

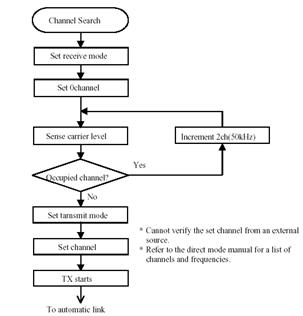

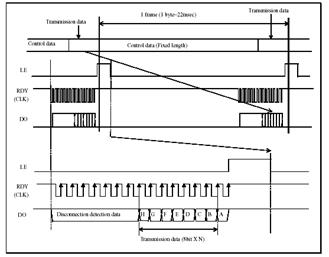

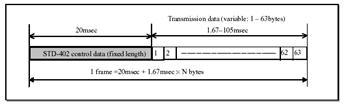

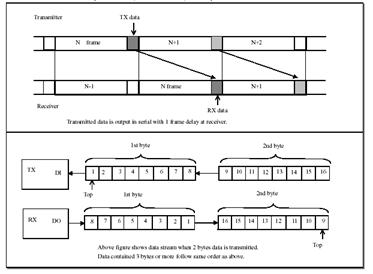

Computer Science, MS Sc. Electrical

Engineering)

Mourad et. al.:

Karlsruhe, July 2006

Veröffentlicht von:

Verein für alternative

Energieforschung e.V.

Content in

short

Abstract 2

1....... Introduction. 4

2....... Project

Management 5

3....... Flight Control

System of an airship. 6

4....... Optimization

of the Flight Control System architecture. 38

5....... Development of

the Ereignisdienstes for the middleware OSA+. 55

6....... Inertial

Measurement Unit 104

Table of Contents. 105

List of figures: 108

List

of Tables. 112

List

of Tables. 112

Literature. 39

7....... Actuator Board. 41

Table

of Contents. ii

List of figures: vi

Literature. 59

Appendix

A.. 61

ANNEX B.. 67

8....... Communication

and User Interface. 76

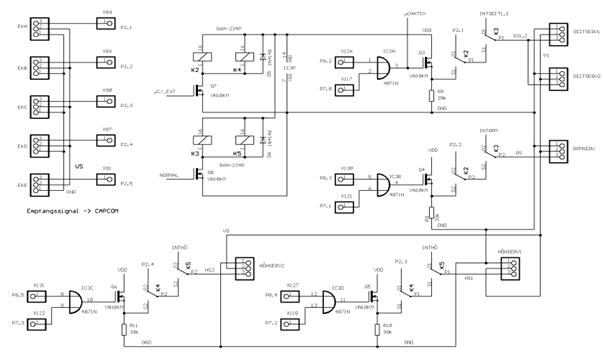

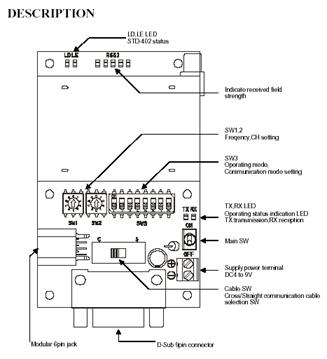

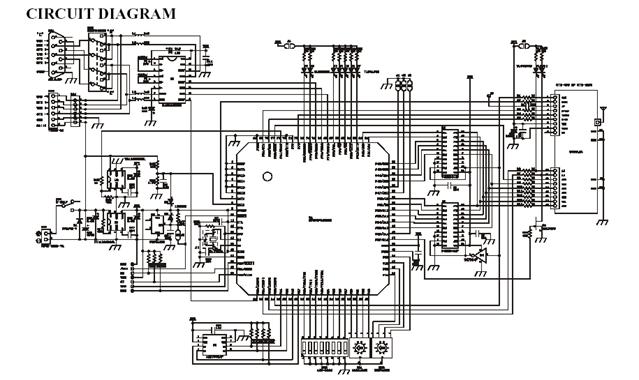

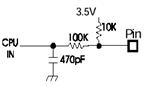

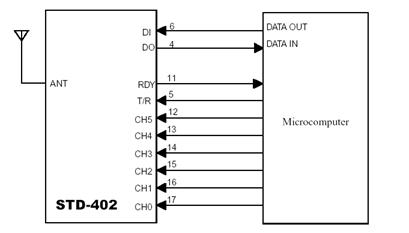

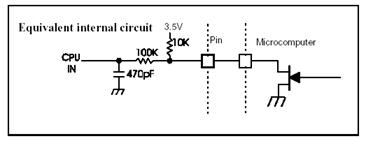

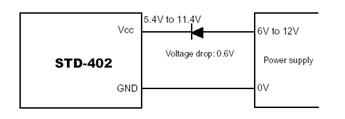

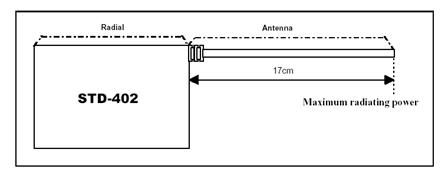

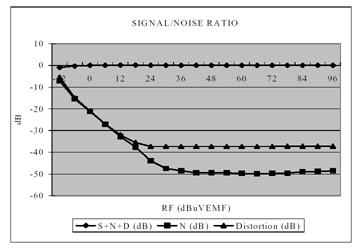

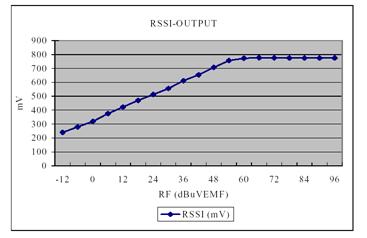

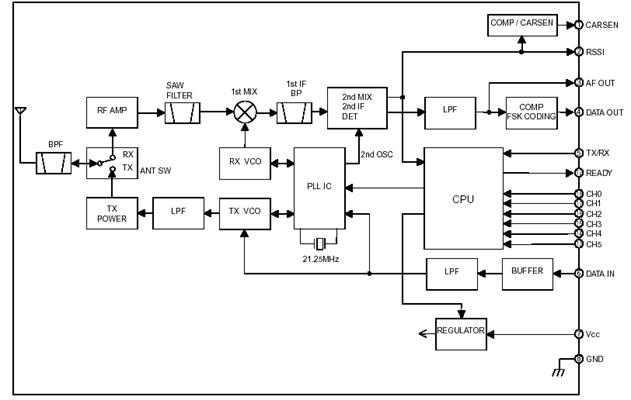

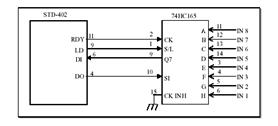

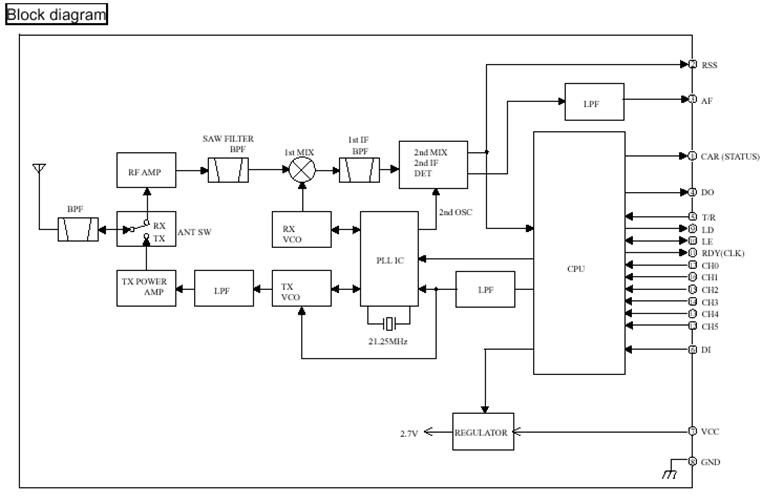

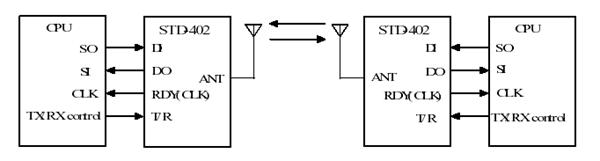

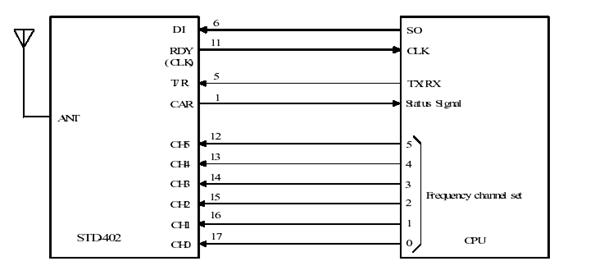

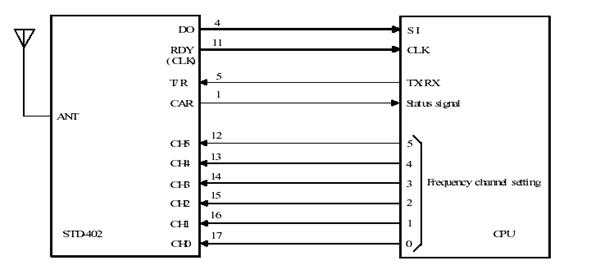

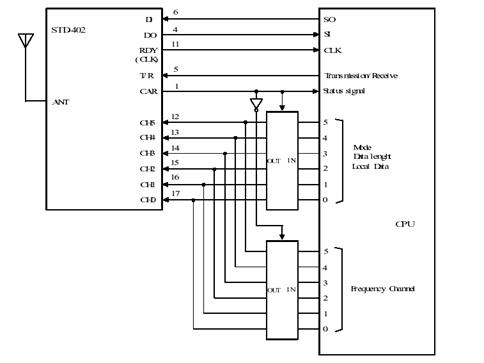

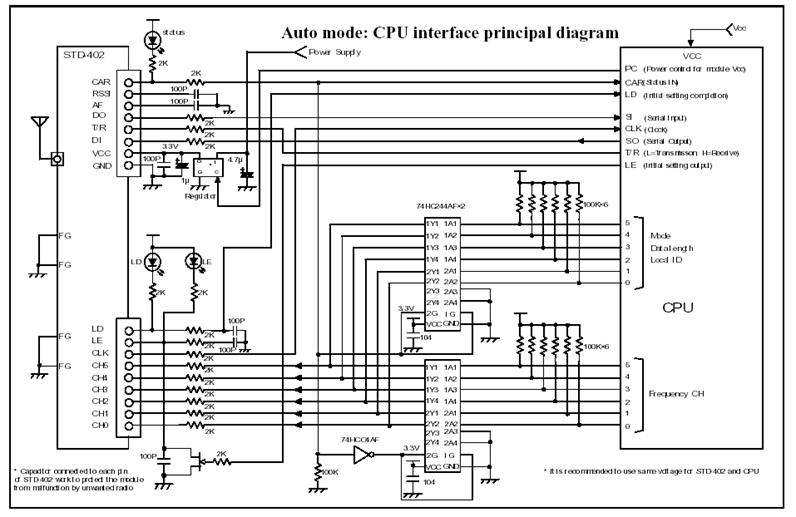

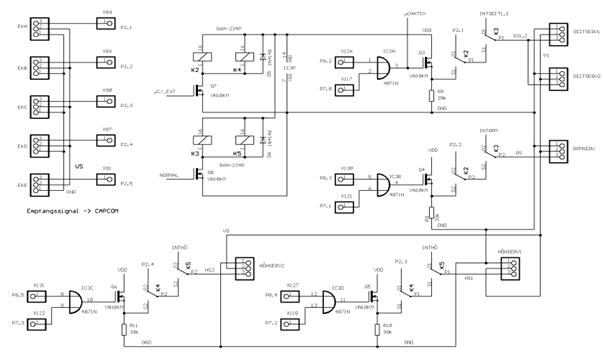

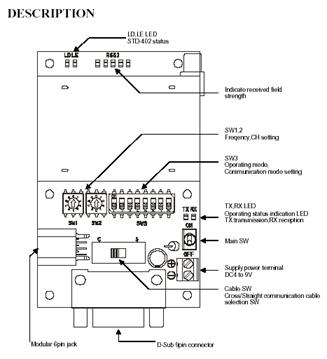

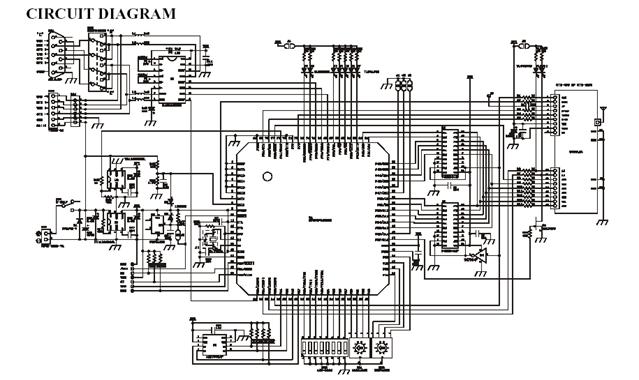

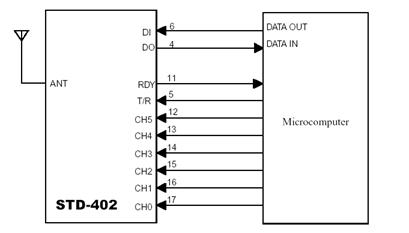

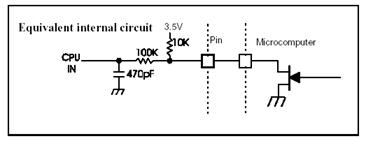

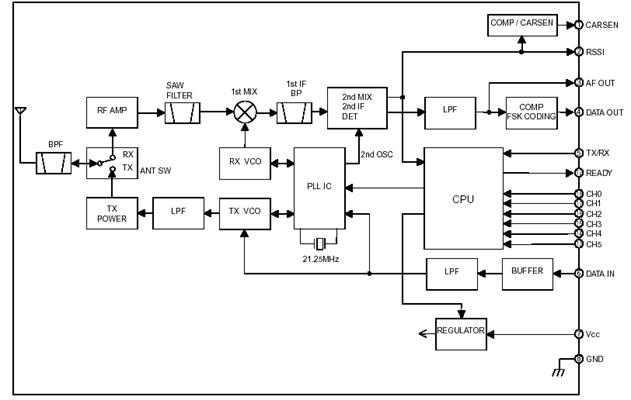

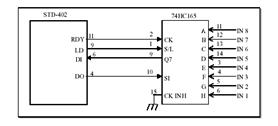

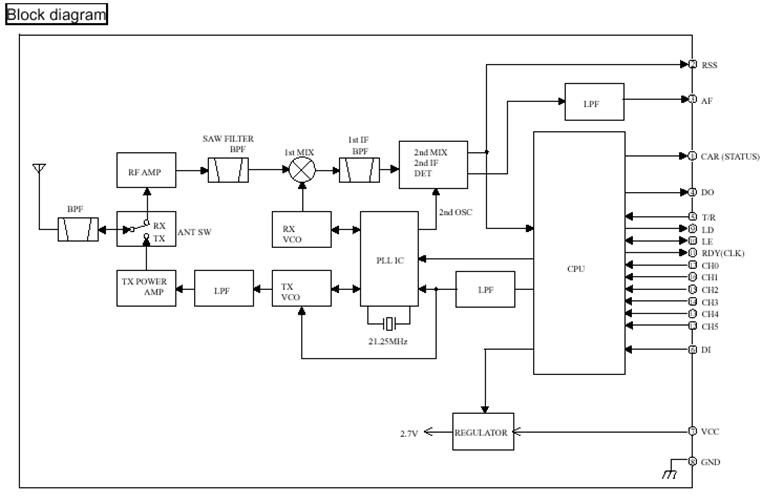

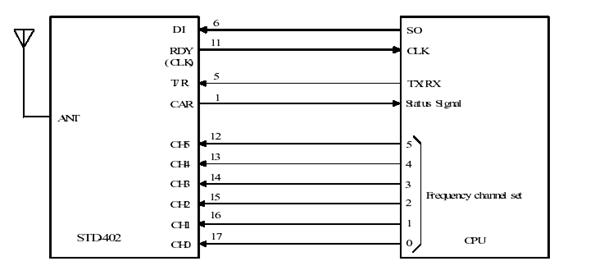

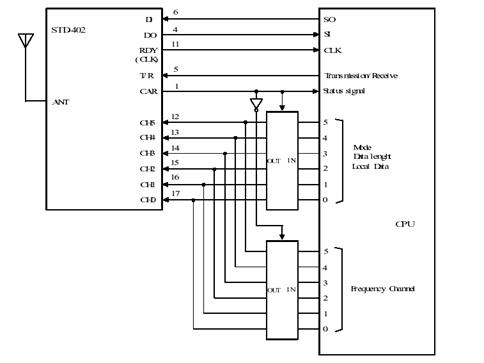

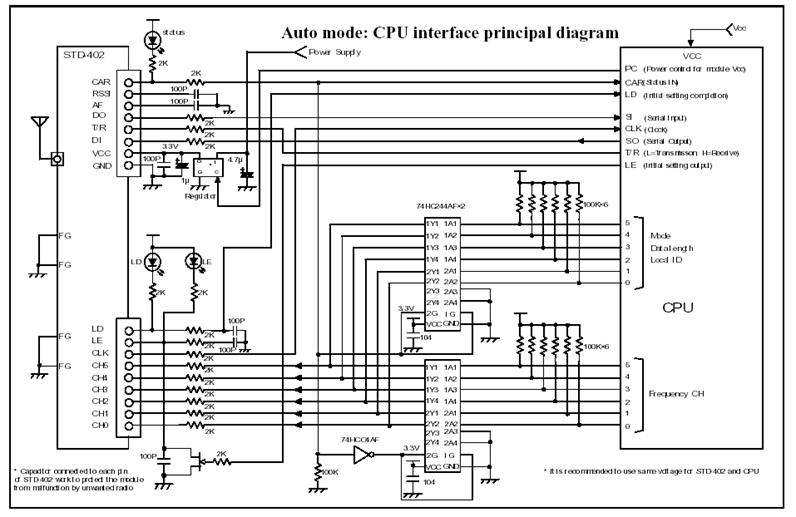

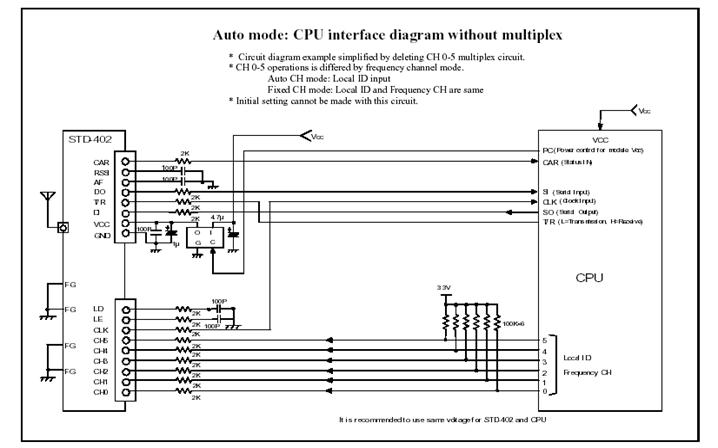

Figure 6.6:

STD-402 Transceiver CIRCUIT

DESIGN.. 103

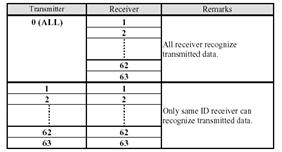

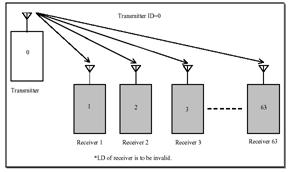

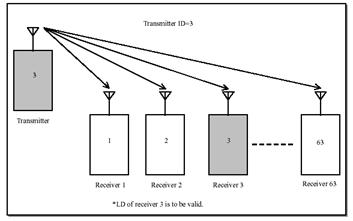

Ack Auto Response Setting. 120

Features. 123

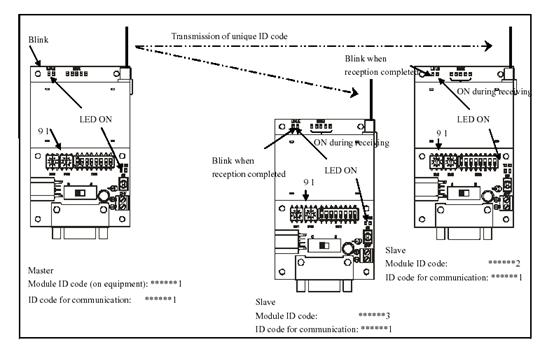

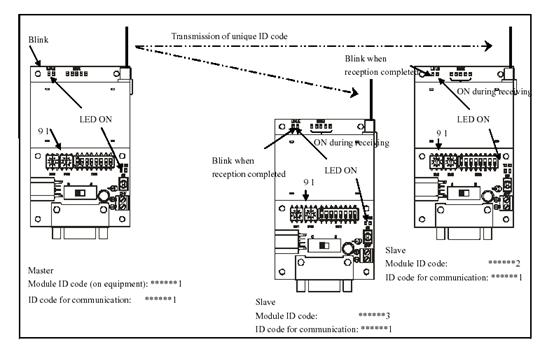

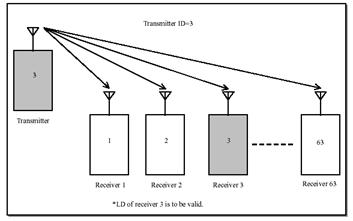

Ø...... Registration of ID.. 142

9....... Annex

D.. 150

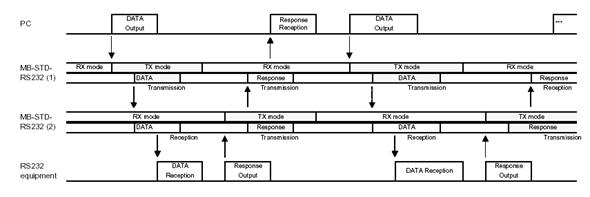

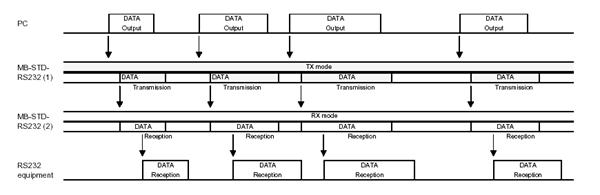

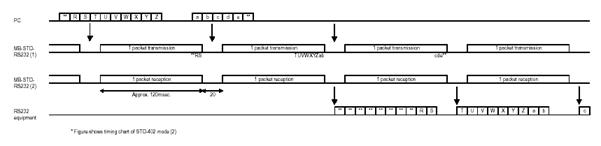

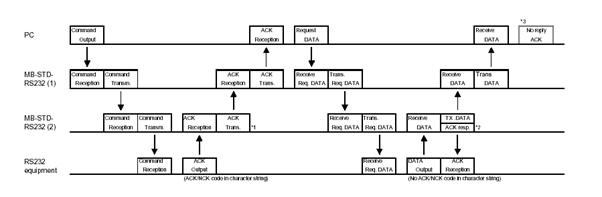

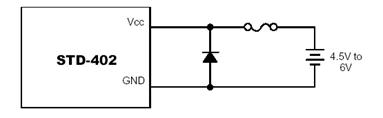

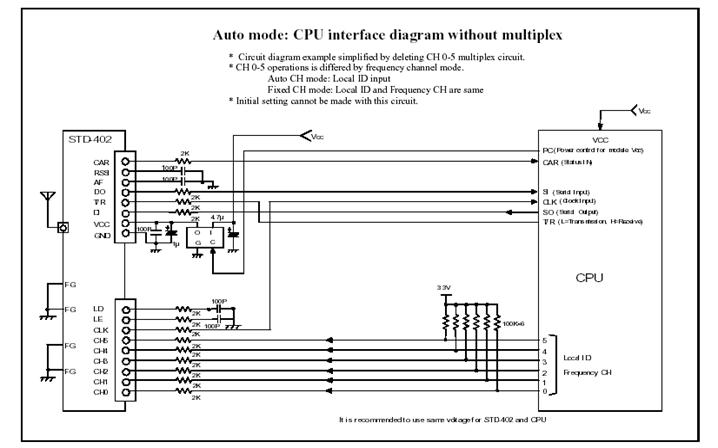

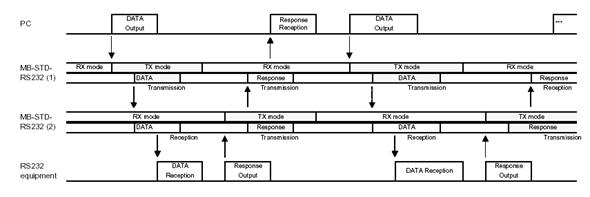

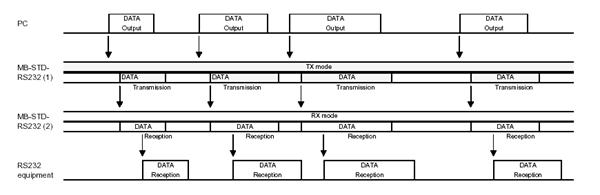

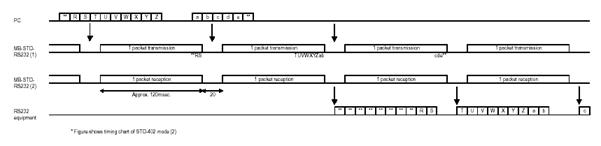

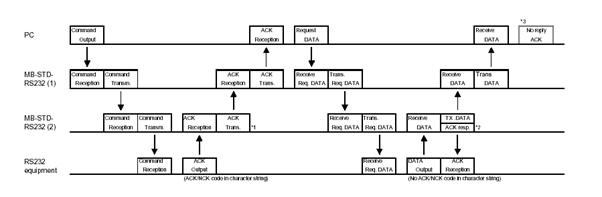

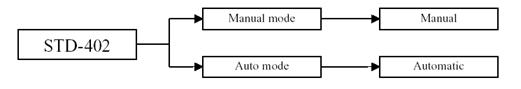

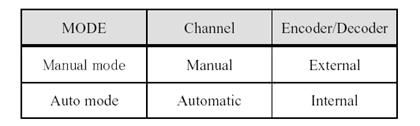

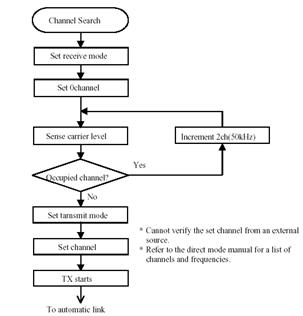

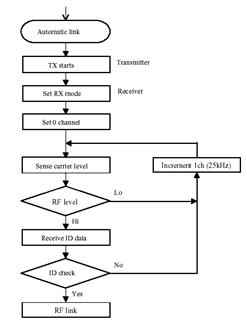

Or the board used to equips the STD-402 is the

MB-STD-RS232, so the this mode (Auto

Mode Operation Guide for CPU Interface) is used like mode of the STD-402

transceiver. 150

10..... Some repairs

on the sensor card and first step integration. 40

11..... Integration. 73

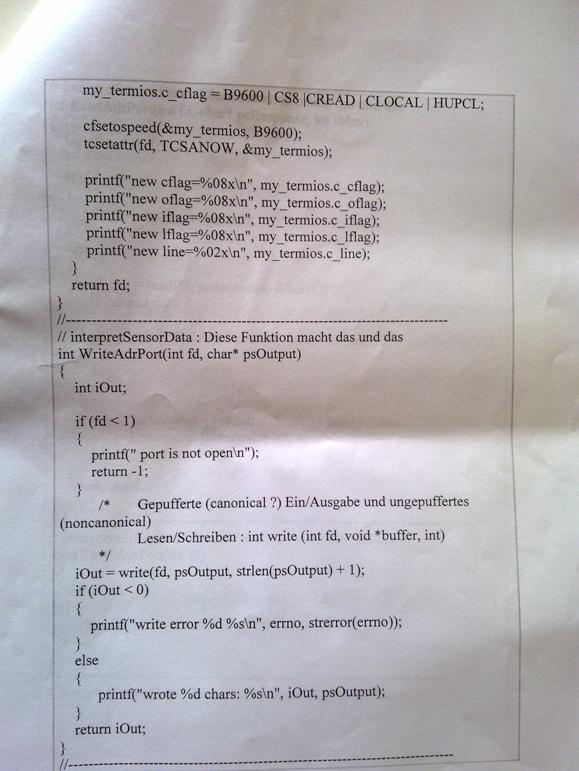

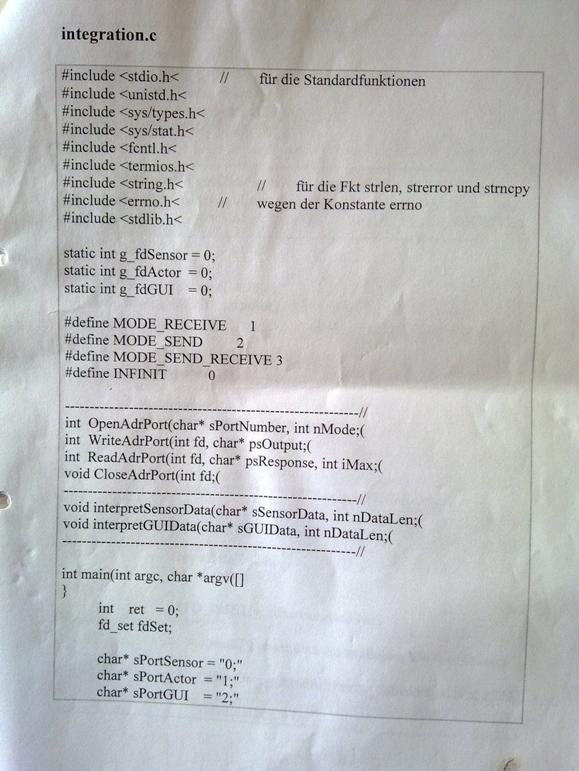

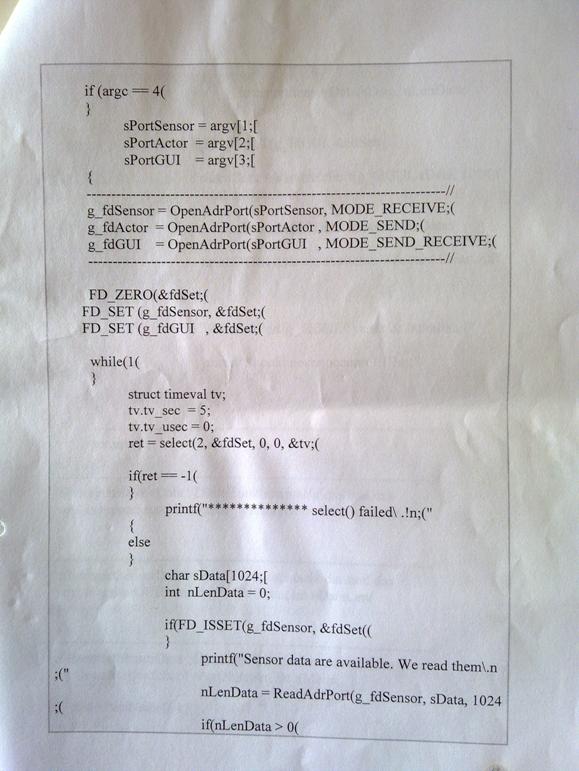

12..... Integration

code in C.. 3

Content

Abstract 2

1....... Introduction. 4

1.1.... The LOTTE

project and the alternative Lotte. 4

2....... Project

Management 5

2.1.... Costs. 5

3....... Flight Control

System of an airship. 6

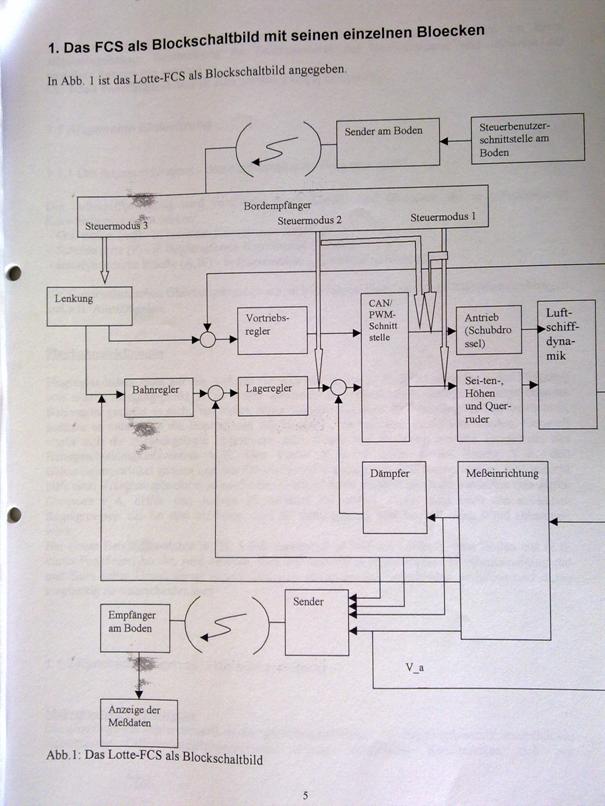

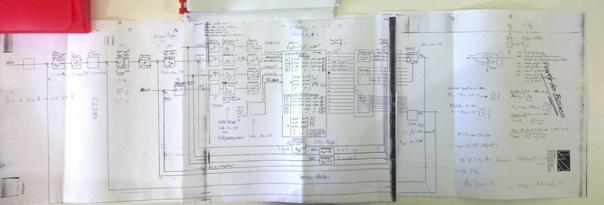

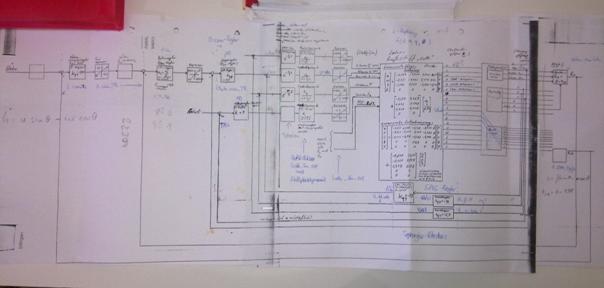

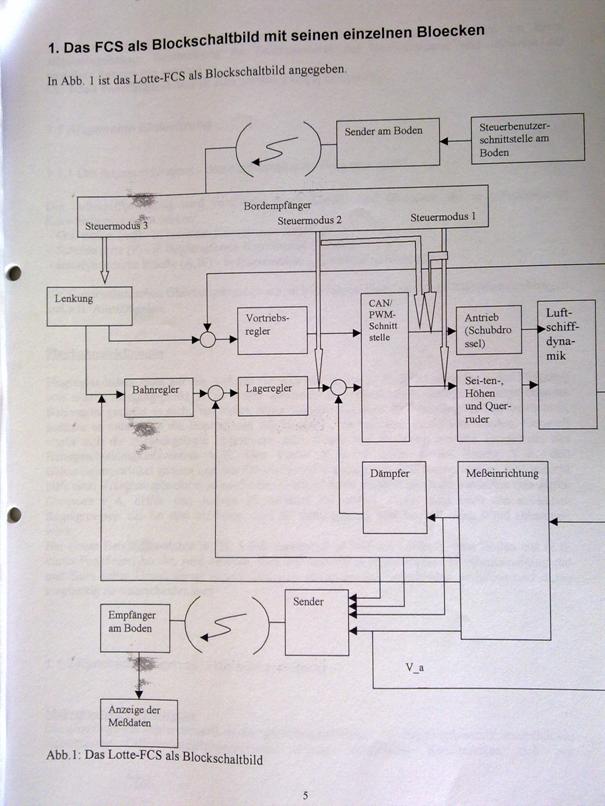

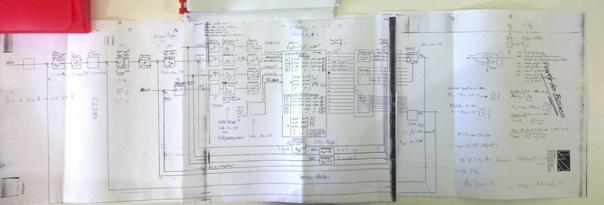

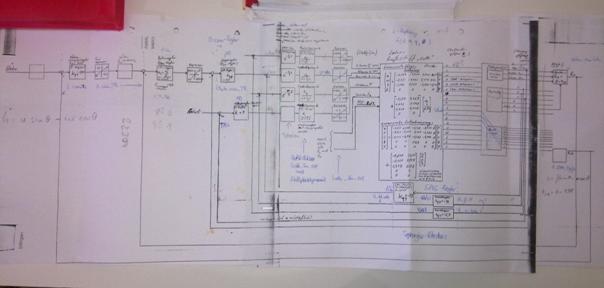

3.1.... Block diagram

of the Control Loops. 37

4....... Optimization

of the Flight Control System architecture. 38

4.1.... The

architecture of the Flight Control System and its simulation on the middleware

OSA+ running on the operating system Windows. 38

4.2.... Results. 39

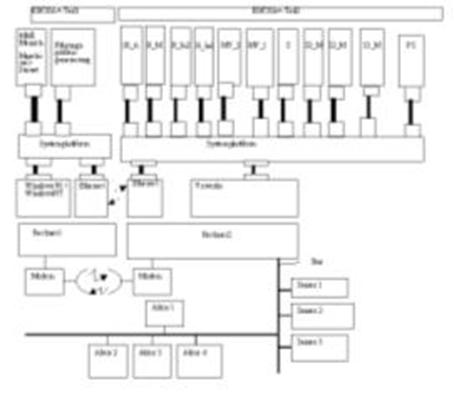

4.2.1.1 System

Architecture of Airship Flight Control System.. 47

4.2.1.2 Simulation

Code (in programming language C) 47

4.2.1.3 Simulation

results. 47

5....... Development of

the Ereignisdienstes for the middleware OSA+. 55

5.1.... Abridged Version. 58

5.2.... The nature of

the task. 58

5.3.... The OSA+ architecture. 58

5.3.1 Introduction. 59

5.3.2 The components of OSA+. 60

5.3.2.1 The Platform.. 60

5.3.2.2 Generic Services. 61

5.4.... Components of

the OSA Eventing service. 62

5.4.1 The time functions. 62

5.4.1.1 The handling

of the time. 62

5.4.1.2 Initialization. 63

5.4.1.3 Functions for time management 65

5.4.2 The event service. 66

5.4.2.1 General Information. 66

5.4.2.2 The

initialization of the Event Service. 68

5.4.2.3 Features of the Ereignisdienstes. 68

5.5.... Short Overview.. 70

5.5.1 Time functions/variables. 70

5.5.2 Features of

the Event Service (Ereignisdienst) 70

5.6.... Configuration. 70

5.7.... Theory of Operation. 72

5.7.1 Osagettime() 72

5.7.2 Osasettime(int,int) 72

5.7.3 Osaaddtime(int,int) 74

5.7.4 Char * osaPrintTime( int, int ) 74

5.7.5 Osainitevents() 75

5.7.6 Int osaAddEvent(uint,uint, uint, uint,uint, uint,uint,

uint, function) 75

5.7.7 Int

osaDelEvent(uint,uint,uint,UINT) 77

5.7.8 OSA_Error

osaGetEventResult(uint,UINT) 77

5.7.9 Internal

functions of the Ereignisdienstes. 78

5.8.... Programming examples. 78

5.8.1 For example:

Changing the Time. 78

5.8.2 Example: Add an Event 79

5.8.2.1 Start a

function at a specified time. 79

5.8.2.2 Repeated start a function. 81

5.8.3 Queries of results. 82

5.8.4 Delete a Events. 82

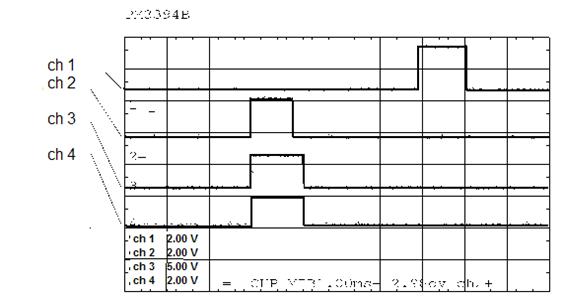

5.9.... Test Runs. 83

5.9.1 Deliver-Test 85

5.9.2 Test run of a

cyclical events with open. 86

5.9.3 Test the

maximum temporal resolution on different systems. 89

5.9.3.1 System 1. 89

5.9.3.2 System 2. 92

5.9.3.3 System 3. 94

5.9.4 Stability tests. 97

5.9.4.1 Exceeding the

maximum acceptable number of Events. 97

5.9.4.2 Exceeding the

maximum acceptable number of events per unit time 98

5.9.4.3 Overrun of the

events per unit time through Zeituberschneidung. 99

5.10.. Results and Outlook. 102

5.11.. ANNEX.. 103

5.11.1 List of all

Windows specific functions. 103

5.12.. Literature. 103

6....... Inertial

Measurement Unit 104

Table of Contents. 105

List of figures: 108

List

of Tables. 112

List

of Tables. 112

6.1.... Introduction. 1

6.1.1 Task. 1

6.1.2 Overview.. 2

6.2.... Basics. 3

6.2.1 Coordinate System.. 4

6.2.2 Calculation of the current position. 5

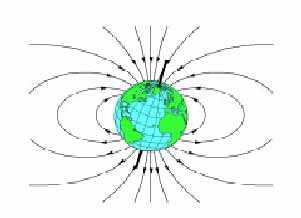

6.2.3 Compass. 6

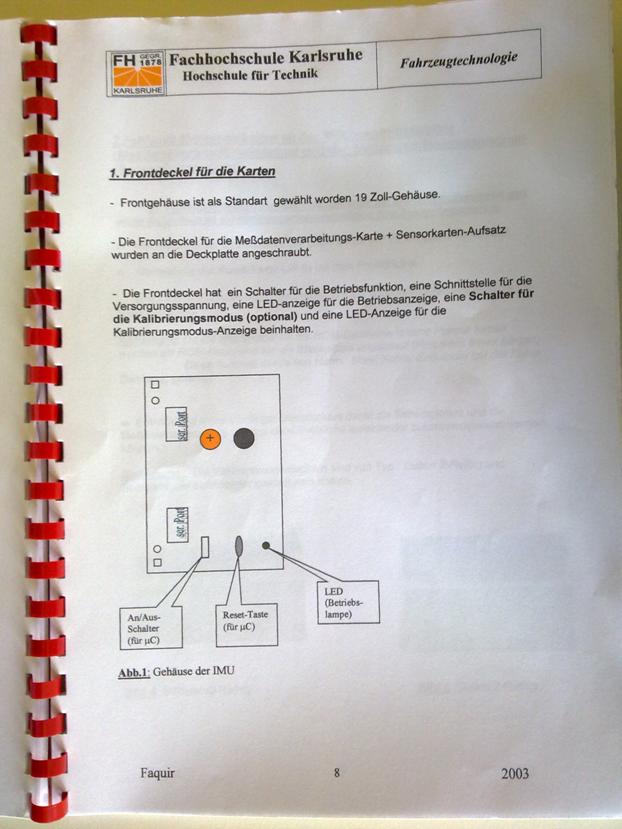

6.3.... Architecture design of the IMU.. 7

6.3.1 Measurement Data Collection (Meßdatenaufnahme) 7

6.3.2 Measurement Data Processing (Meßdatenaufbereitung) 7

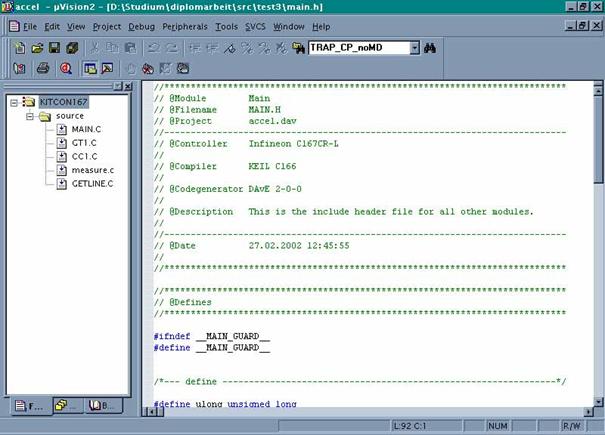

6.4.... Development environment 9

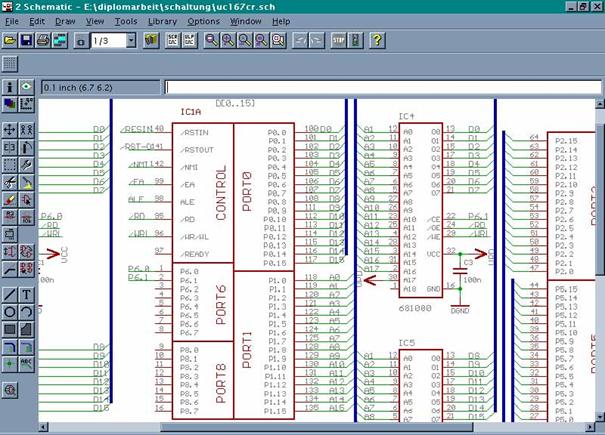

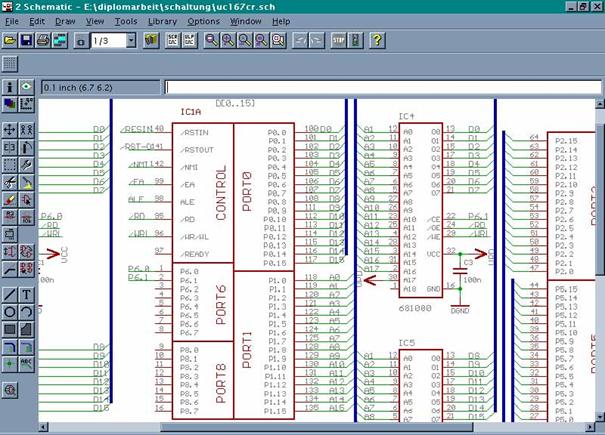

6.4.1 Hardware-Entwicklungsumgebung. 9

6.4.2 Software Development Environment 10

6.5.... Realization of the IMU.. 11

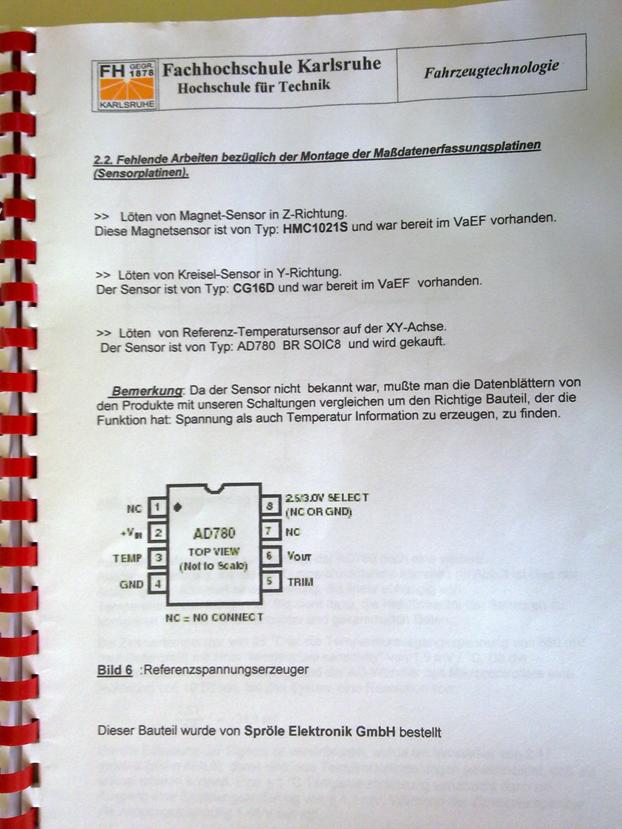

6.5.1 Meßdatenaufnahme. 11

6.5.1.1 Circuit Design

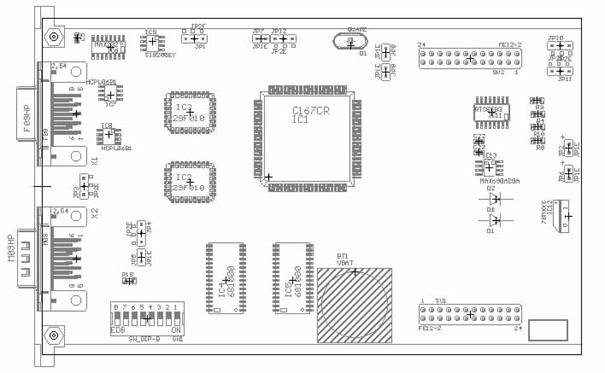

for the Meßdatenaufnahme. 11

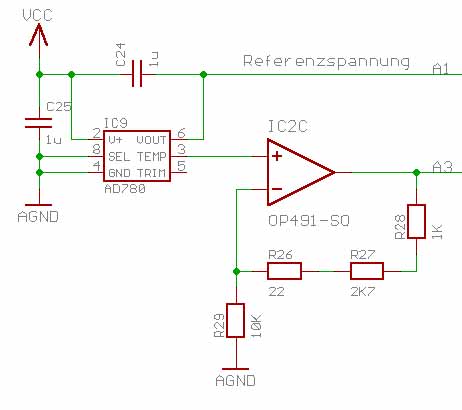

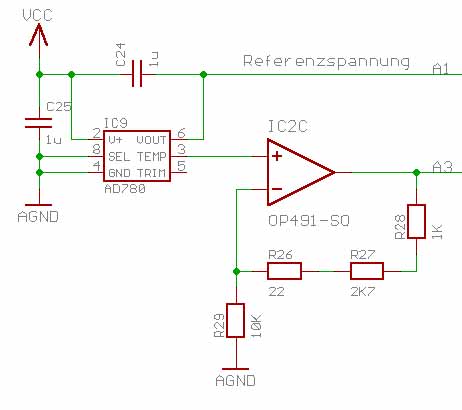

6.5.1.2 Reference Voltage. 18

6.5.2 Board layout

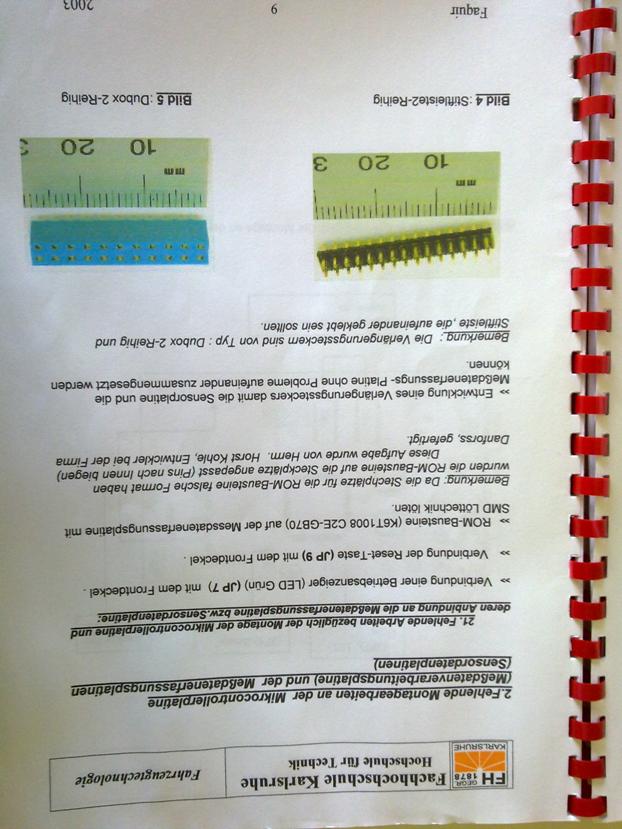

design for the Meßdatenaufnahme (Measurement data collection) 19

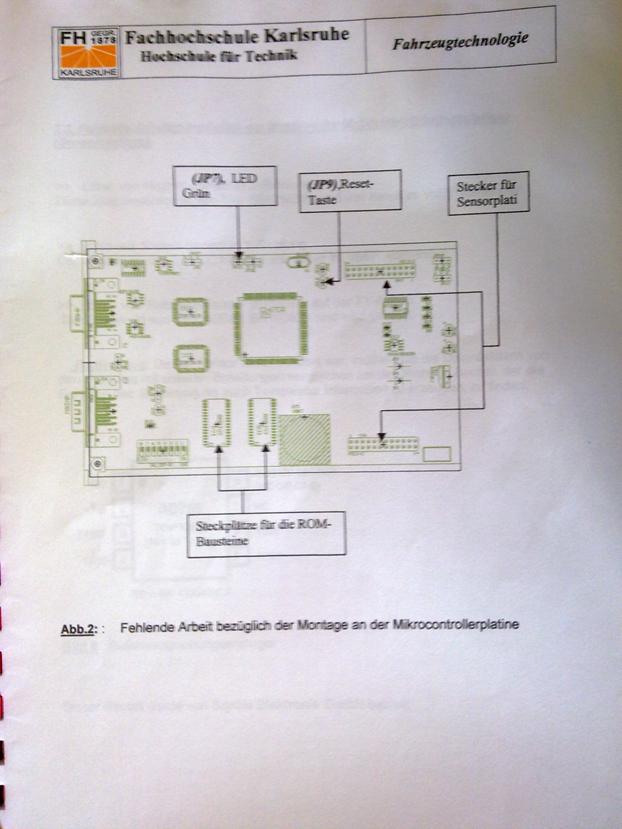

6.5.3 Meßdatenaufbereitung. 21

6.5.3.1 Circuit Design for the

Meßdatenaufbereitung. 22

6.5.4 Board layout

design for the Meßdatenaufbereitung. 24

6.5.4.1 The software for the

Meßdatenaufbereitung. 26

6.5.4.2 User Interface. 29

6.6.... Test Results. 33

6.6.1 Hardware-Test 33

6.7.... Test of

the overall system with the microcontroller (C167) 34

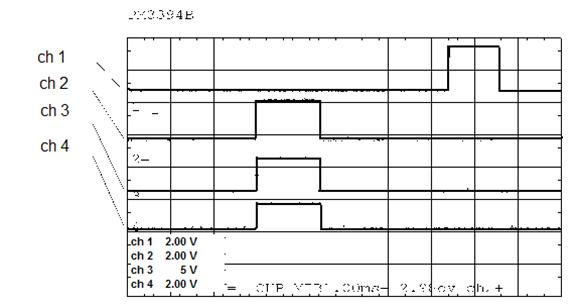

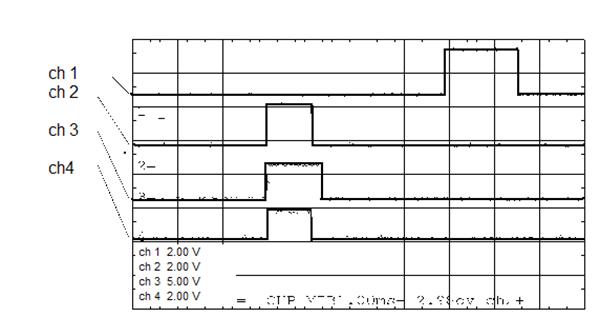

6.7.1 Gesamtsystem-Test 1. 34

6.7.2 Gesamtsystem-Test 2. 36

6.7.3 Gesamtsystem-Test 3. 36

6.8.... Summary and outlook. 38

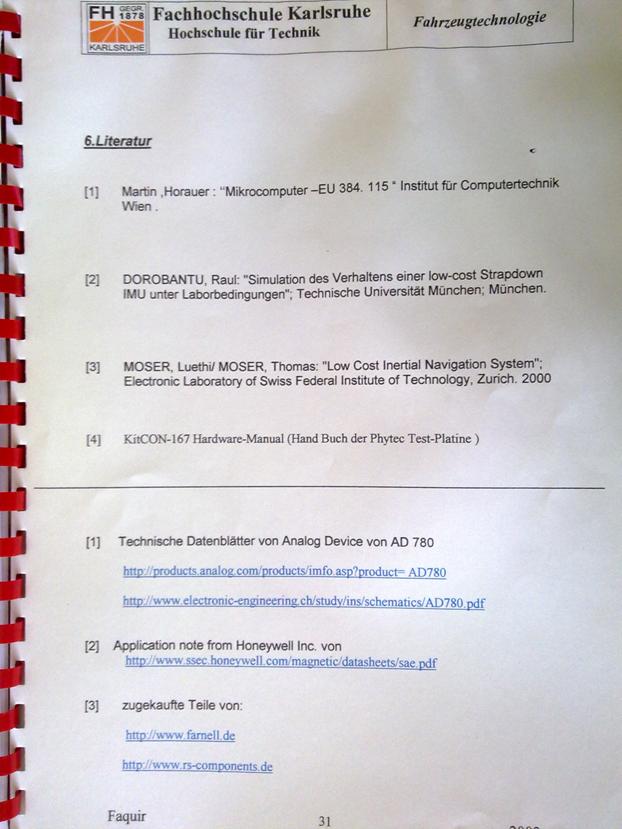

Literature. 39

7....... Actuator Board. 41

Table

of Contents. ii

List of figures: vi

7.1.... Introduction. 1

7.1.1 The Solarluftschiff Lotte. 1

7.1.2 Task. 2

7.1.3 Overview.. 2

7.2.... Basics. 3

7.2.1 Real-time systems. 3

7.2.2 Hardware. 3

7.2.2.1 Components and classifications. 3

7.2.2.2 The microcontroller family C166. 4

7.2.2.3 The C167 microcontroller family. 5

7.2.2.4 The memory

organization of the C167) 6

7.2.2.5 The interrupt

system of the C167) 8

7.2.2.6 The Timereinheiten. 10

7.2.2.7 Capture Compare Unit (Capcom) 11

7.2.2.8 The PWM Pulsweiten-Einheit 13

7.2.2.9 Analog Digital Converter (ADC) 14

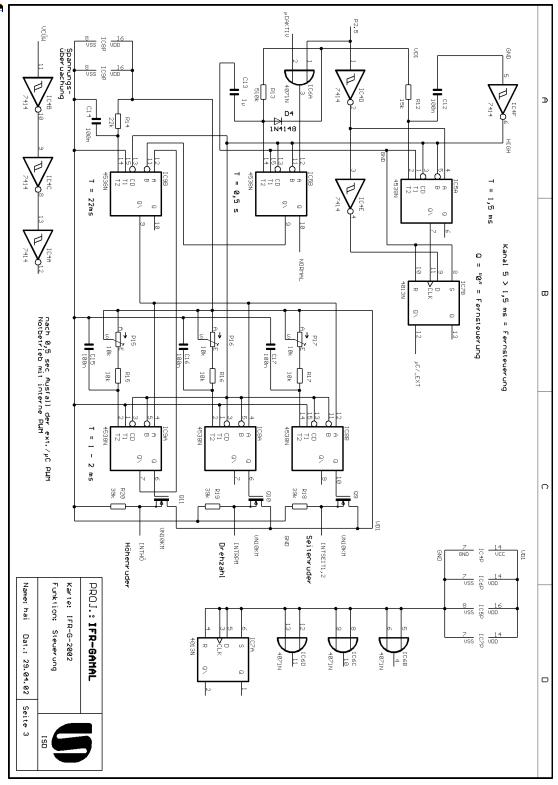

7.2.3 Control of servo motors. 15

7.3.... Architecture

design of the Aktorik-Ansteuerungseinheit (engl, Actuator Control Unit (ACU) 17

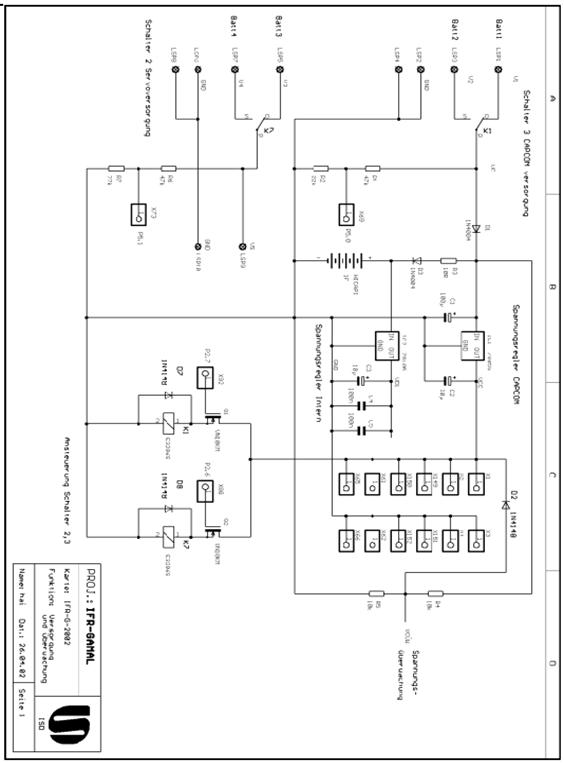

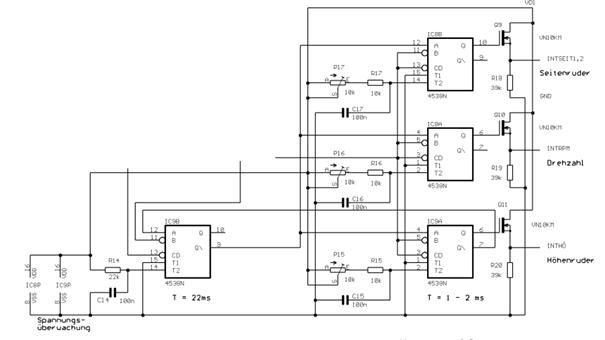

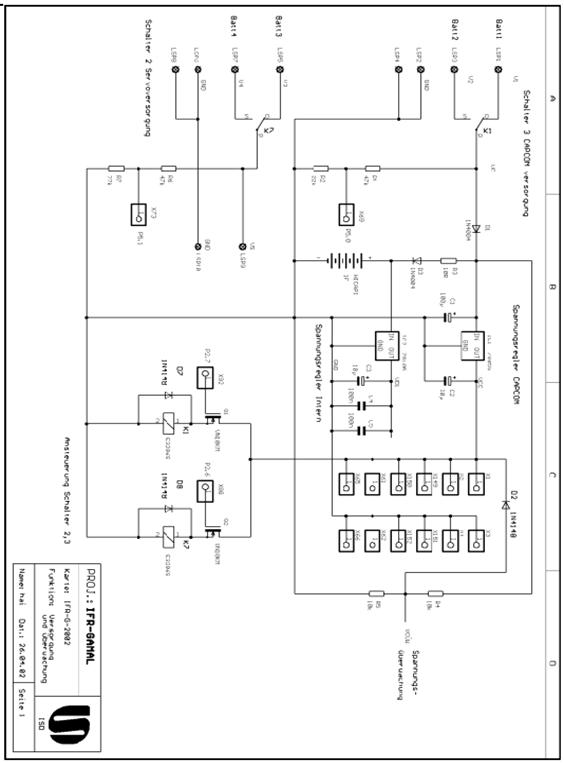

7.3.1 Voltage regulation. 17

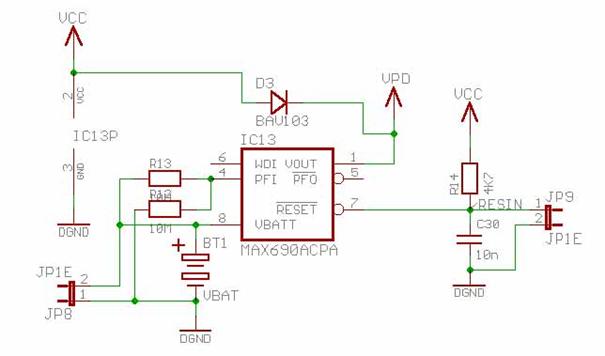

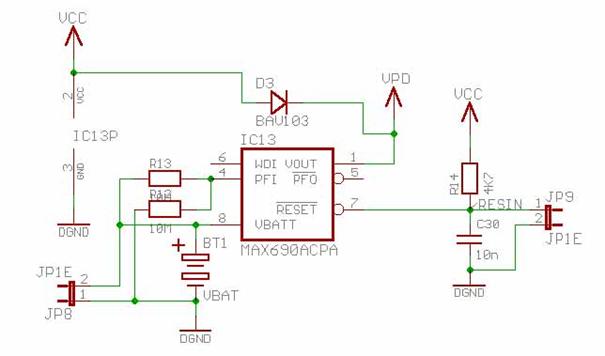

7.3.2 Betriebsspannungsuberwachung. 18

7.3.3 Basisbetriebszustands-Einstellung. 18

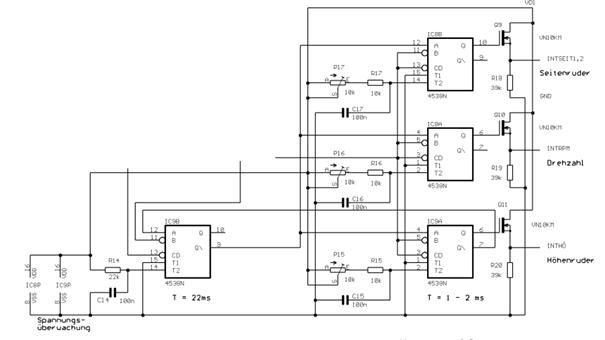

7.3.4 Steuersignal-Erzeugung. 18

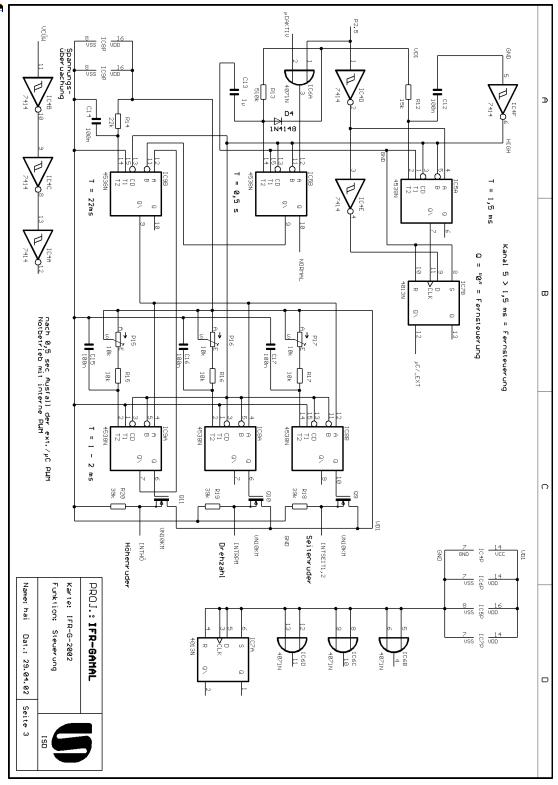

7.3.5 Notsteuerungsbaugruppe. 19

7.3.6 Operating conditions of the ACU.. 20

7.3.7 Modularity of the ACU.. 20

7.4.... Development environment 23

7.4.1 Hardware-Entwicklungsumgebung. 23

7.4.2 Software Development Environment 24

7.5.... Realization of the ACU.. 25

7.5.1 Versorgungsspannungs-Stabilisierung. 25

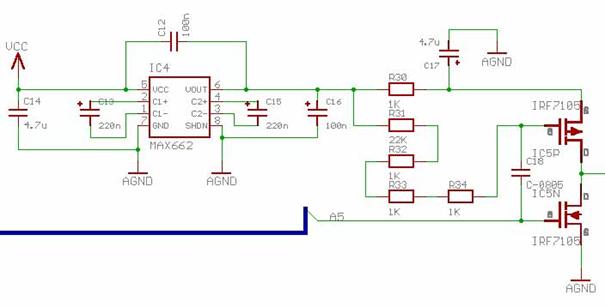

7.5.1.1 Circuit Design for the Versorgungsspannungs-Stabilisierung. 26

7.5.2 Betriebsspannungsuberwachung. 28

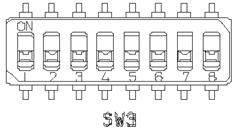

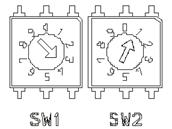

7.5.3 Basisbetriebszustands-Einstellung. 29

7.5.3.1 Circuit Design for the

Basisbetriebszustands-Einstellung. 32

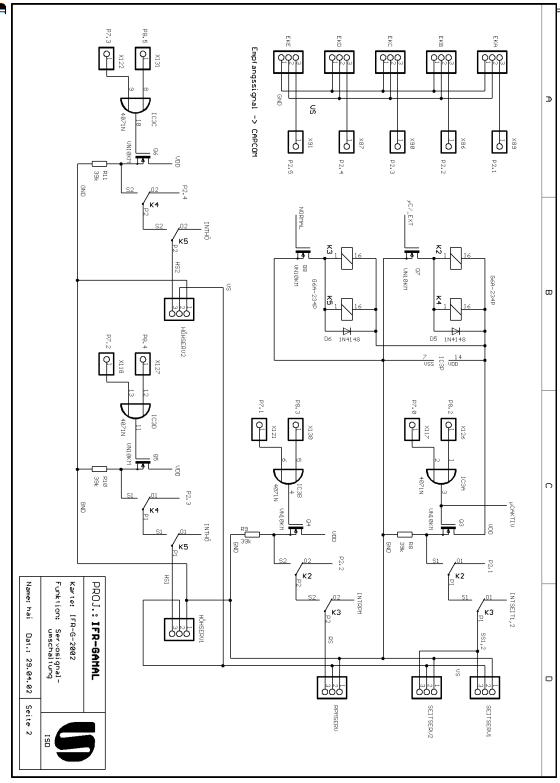

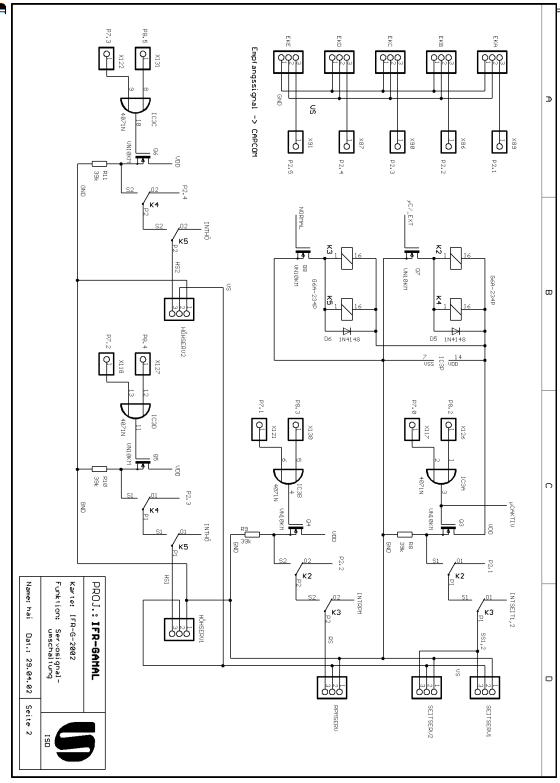

7.5.4 Steuersignal-Erzeugung. 33

7.5.4.1 The hardware

of the Steuersignal-Erzeugung. 36

7.5.4.2 The monitoring

and the forwarding of the PWM-signals from the remote control (normal operation

(B) 36

7.5.4.3 Level 1 Notsteuersignal-Erzeugung. 41

7.5.5 Notsteuerungsbaugruppe. 44

7.5.5.1 Circuit Design

for the monitoring of the control signals on the output of the ACU and the

channel5-output of the Fernsteuerempfangers. 44

7.5.5.2 Circuit Design for the

Notsteuerungsbaugruppe. 45

7.5.5.3 Circuit Design

for the forwarding of the PWM-signals from Fernsteuerungsempfanger (

Luftschiff-Startphasen -operation) 46

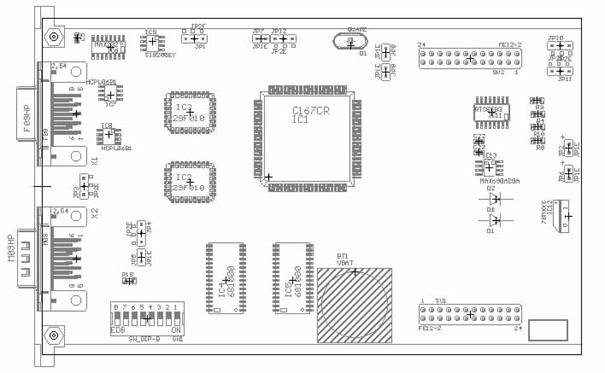

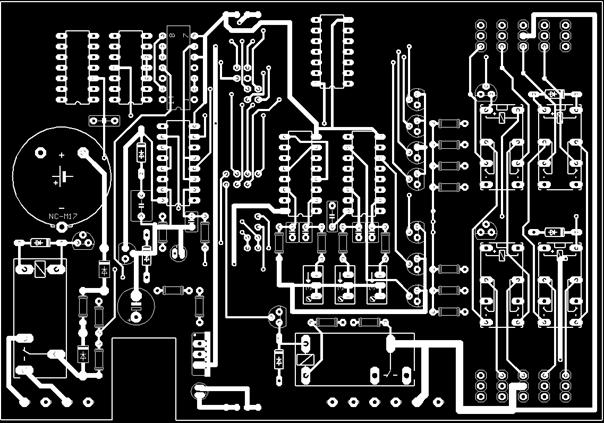

7.5.6 Layout design of board 1 (

"Voltage regulation", " Basisbetriebszustands-Einstellung "

and " Notsteuerungs-Baugruppe ") 46

7.5.7 The circuit

boards of the ACU.. 47

7.6.... Experimental results. 49

7.6.1 Structure of the Testplatzes. 49

7.6.2 Experiments and test sequence. 50

7.6.3 The series of tests. 50

7.6.3.1 Test 1. 51

7.6.3.2 Test 2. 52

7.6.3.3 TEST3. 53

7.6.3.4 Test 4. 54

7.6.3.5 Test 5. 55

7.7.... Summary and outlook. 57

Literature. 59

Appendix

A.. 61

ANNEX B.. 67

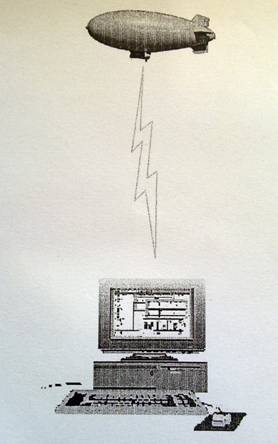

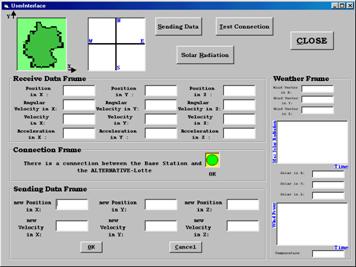

8....... Communication

and User Interface. 76

8.1.... Introduction. 76

8.1.1 The LOTTE

project and the alternative Lotte. 76

8.1.2 Development

method. 77

8.1.3 Working task

and realization approach. 77

8.1.4 Overview.. 77

8.2.... Basics. 78

8.2.1 The V-Model 78

8.2.2 Structured

Analysis (SA) / Structured Design (SD) 79

8.2.3 Transceivers. 81

8.3.... Requirements Specification. 81

8.3.1 The Graphical User Interface

(GUI) 81

8.3.1.1 Software

Requirements Specification. 82

8.3.2 Specifications

for the transceiver. 86

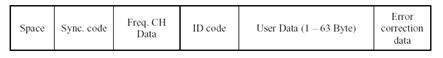

8.3.3 Communication

Protocol for User Data. 86

8.3.4 Handshaking. 88

8.4.... Architecture Design. 88

8.5.... Development Environments. 90

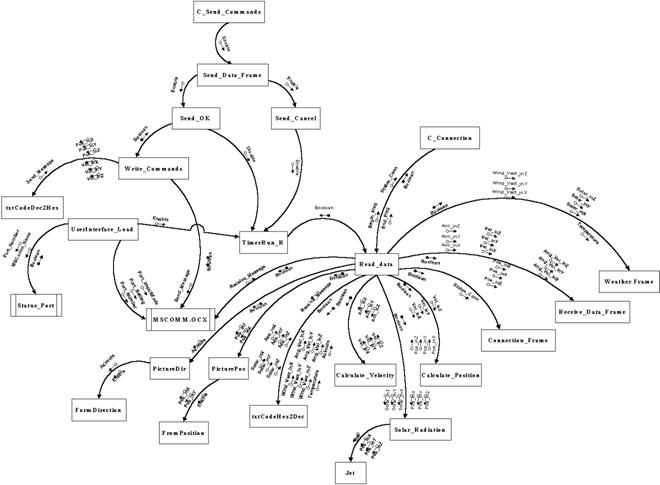

8.6.... Design and Implementation. 90

8.6.1 SA / SD and

Implementation for the base station program.. 90

8.6.1.1 SA (Structured

Analysis) 90

8.6.1.2 SD (Structured

Design) 94

8.6.1.3 Implementation. 97

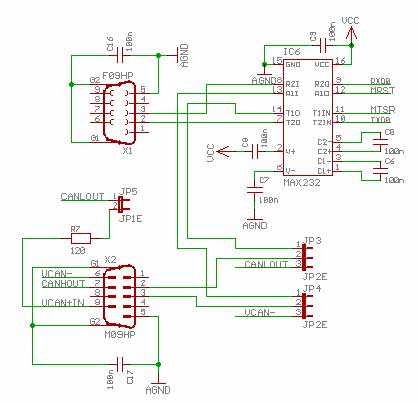

8.6.2 Communication

part on the board system on the airship. 100

8.6.2.1 The tranceiver. 100

8.6.2.2 The

communication software on the embedded board computer. 105

8.7.... Component Tests. 106

8.7.1 Transceiver

test 106

8.7.2 User interface

laboratory test with two PCs. 109

8.7.3 Test of the

user interface on the target system.. 111

8.8.... Annex A.. 112

8.9.... Annex B. 122

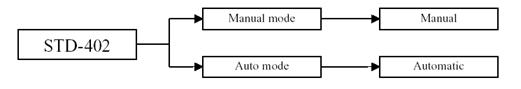

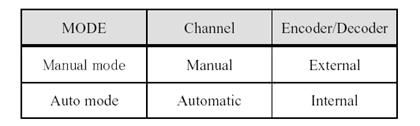

8.9.1 Block diagram

of the STD-402 transceiver in Direct Mode. 136

8.10.. Annex C.. 137

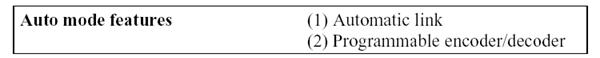

¨ STD-402TR [Auto Mode

Operation Guide] 137

8.10.1 General 137

8.10.2 Features. 138

8.10.3 Application

Examples. 138

8.10.4 Configuration. 138

Ø...... Registration of ID.. 142

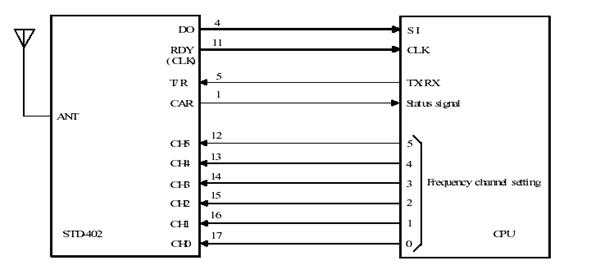

8.10.5 diagram of the

STD-402 transceiver in Auto Mode. 148

9....... Annex

D.. 150

9.1. 154

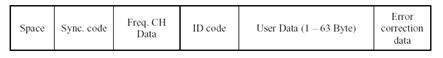

9.2.... STD-402 Data Format 154

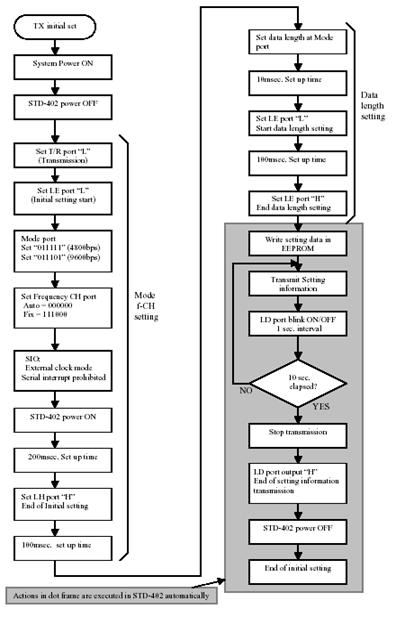

9.2.1 Transmitter :

Initial setting flow chart 156

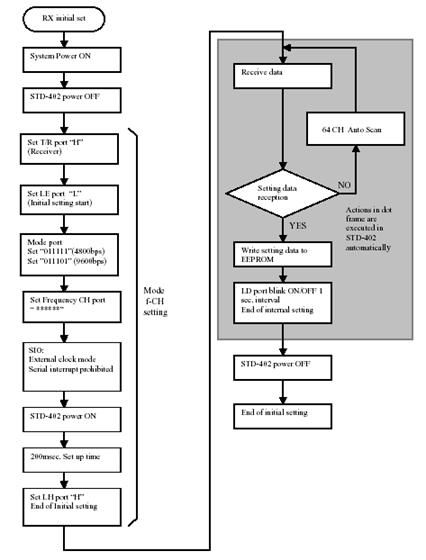

9.2.2 Receiver: Flow

chart at power ON.. 162

9.3.... Annex E:

Visual Basic code for the user interface program.. 5

9.4.... Annex F: C program code. 32

9.5.... Annex G.. 36

10..... Some repairs

on the sensor card and first step integration. 40

11..... Integration. 73

11.1.. Abstract 73

11.2.. Introduction. 77

11.2.1 The

Lotte-Projekt and the "alternative Lotte". 77

11.3.. Development environment 79

11.4.. Architecture Design and Implementation. 80

11.5.. Literature. 1

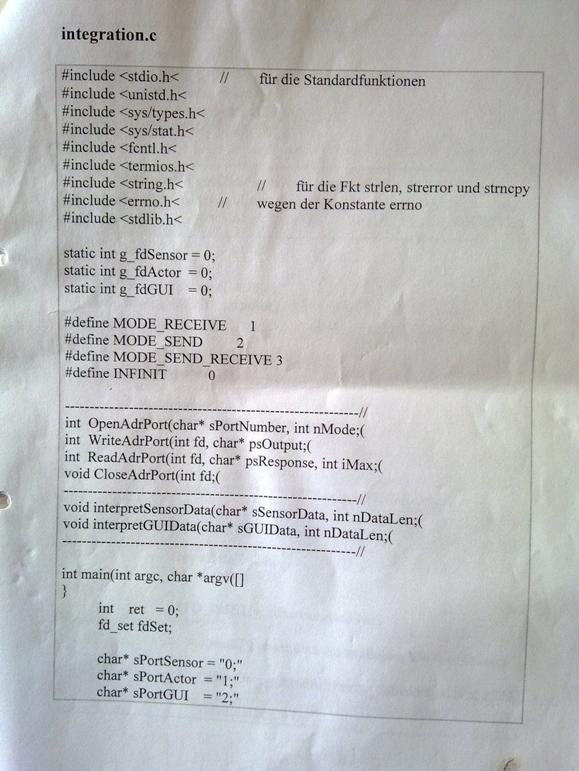

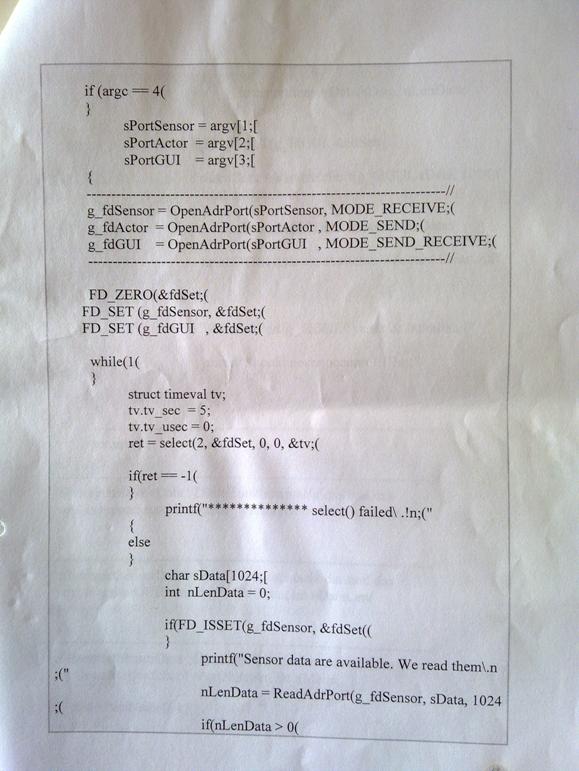

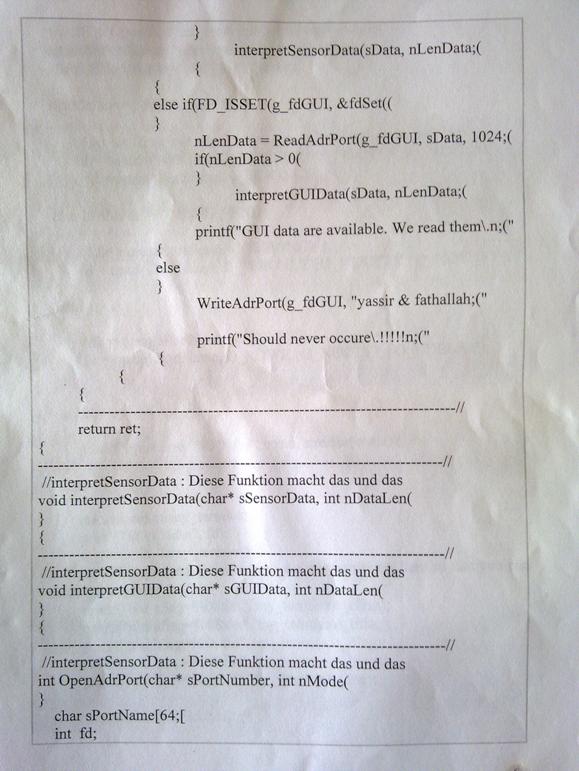

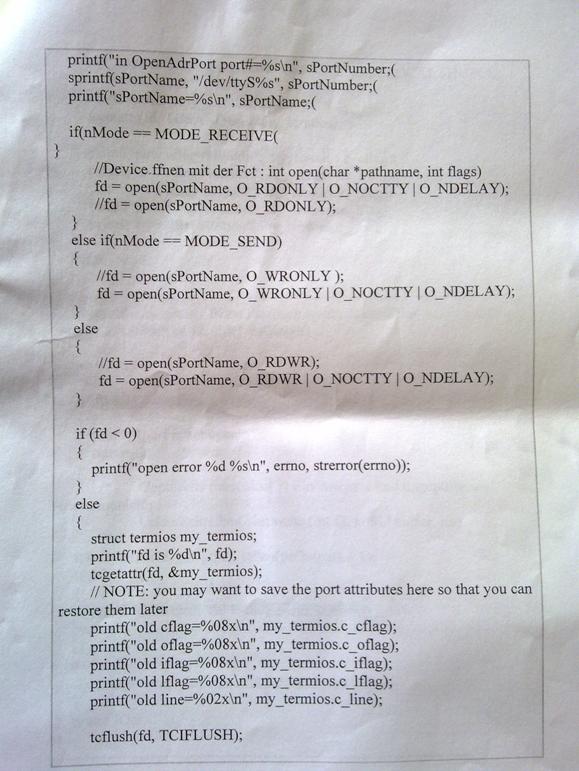

12..... Integration

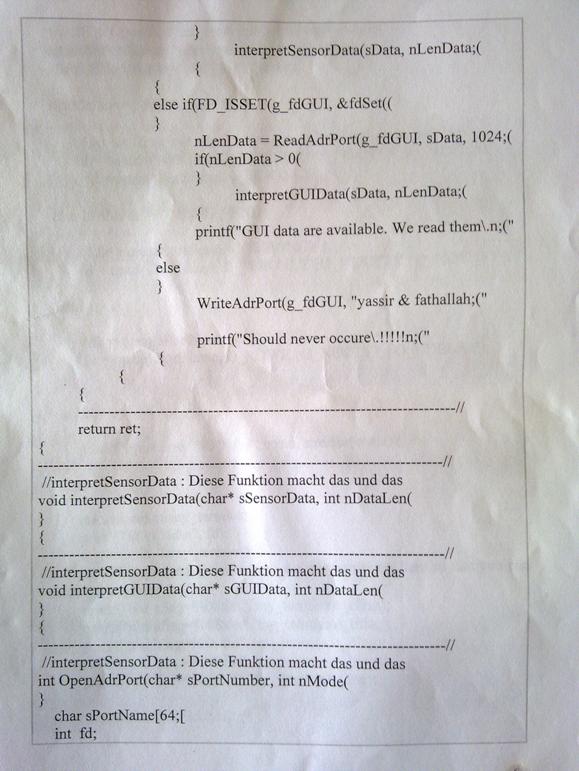

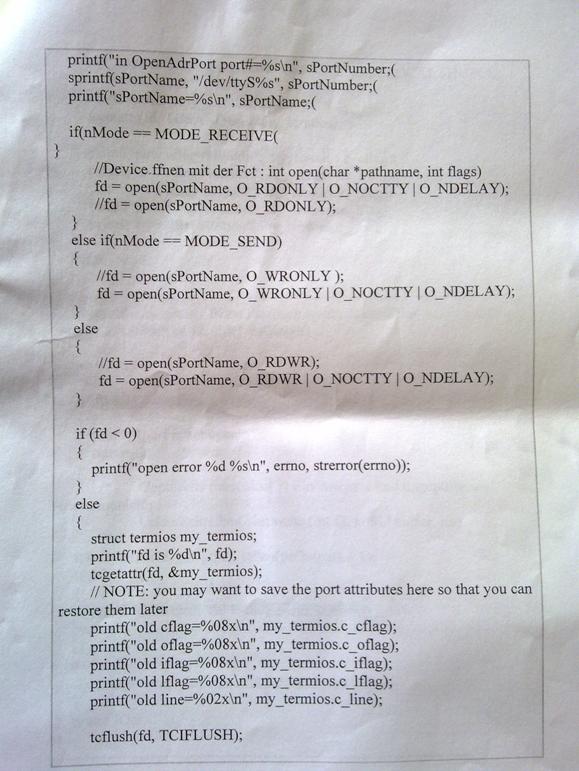

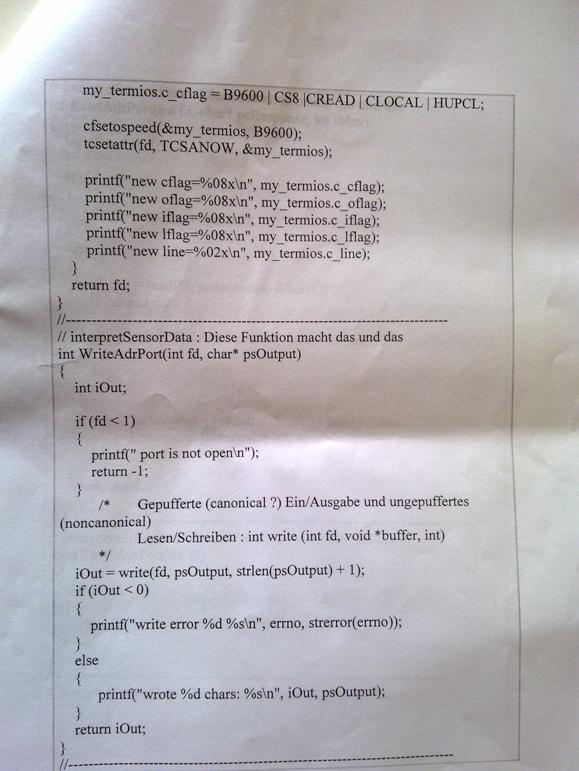

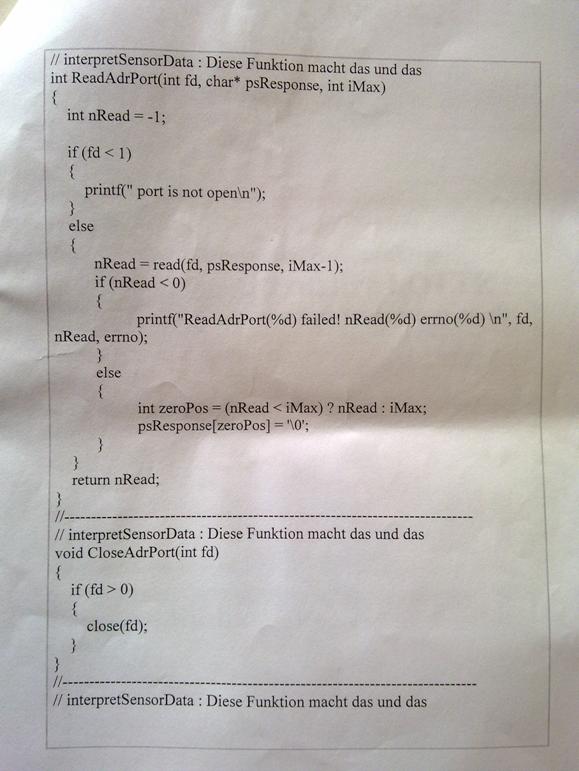

code in C.. 3

ijk

Abstract

In this project report the "alternative Lotte" airship flight

control system project and its results for August 2000 July 2006 are described.

In summer 2006 the project was cancelled.

The alternative Lotte project aimed to improve the flight control system

of the solar airship "Lotte" of University of Stuttgart.

|

|

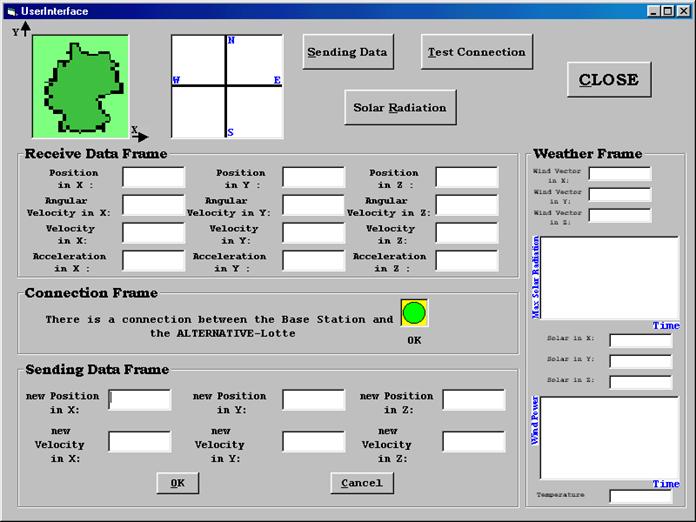

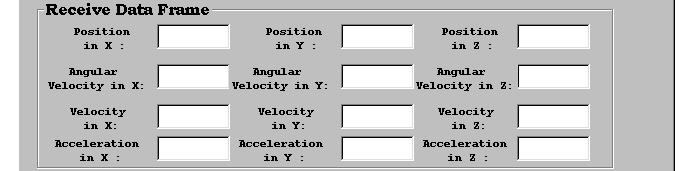

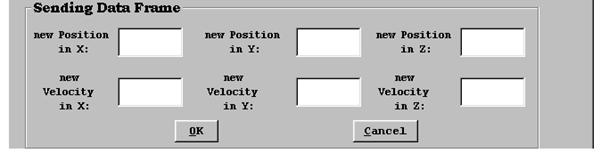

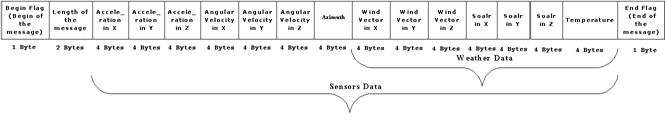

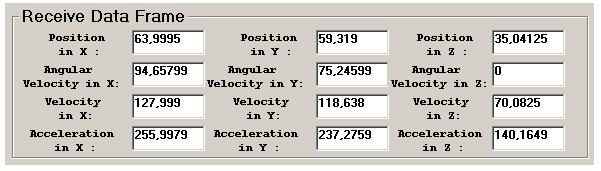

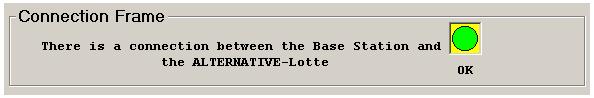

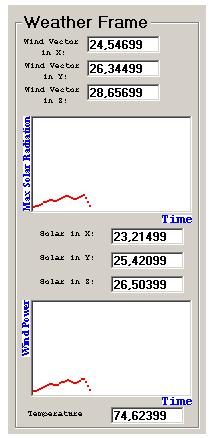

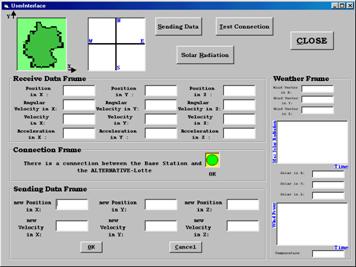

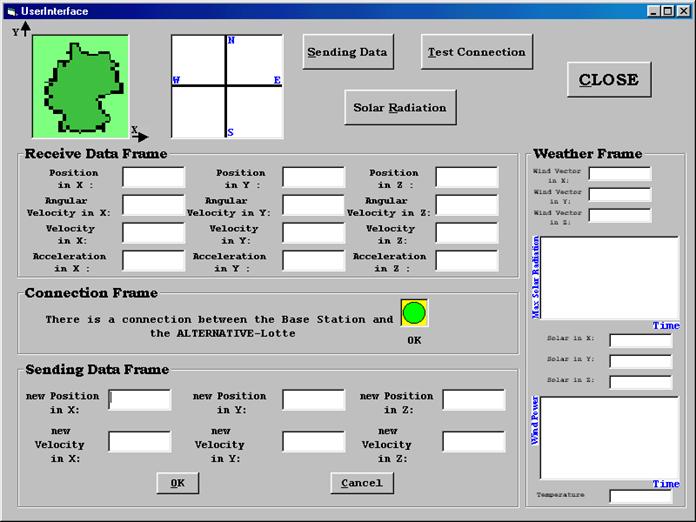

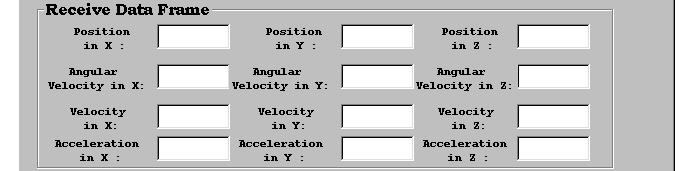

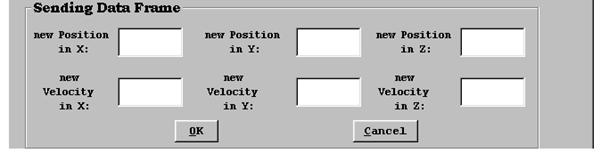

The user interface is the link

between the user and the alternative LOTTE, a measurement vehicle for solar

radiation and wind power. Its purpose is allowing the user to control the

alternative LOTTE from the base

station, so by using the User Interface, the user can set data to the

alternative LOTTE (new position, new velocity ...) and get data from the

alternative LOTTE (acceleration, angular velocity, azimuth, temperature,

wind vector, Solar radiation ...). The user interface is the link

between the user and the alternative LOTTE, a measurement vehicle for solar

radiation and wind power. Its purpose is allowing the user to control the

alternative LOTTE from the base

station, so by using the User Interface, the user can set data to the

alternative LOTTE (new position, new velocity ...) and get data from the

alternative LOTTE (acceleration, angular velocity, azimuth, temperature,

wind vector, Solar radiation ...).

|

|

The airship can be controlled from the ground or fly automatically to

specified coordinates.

|

|

|

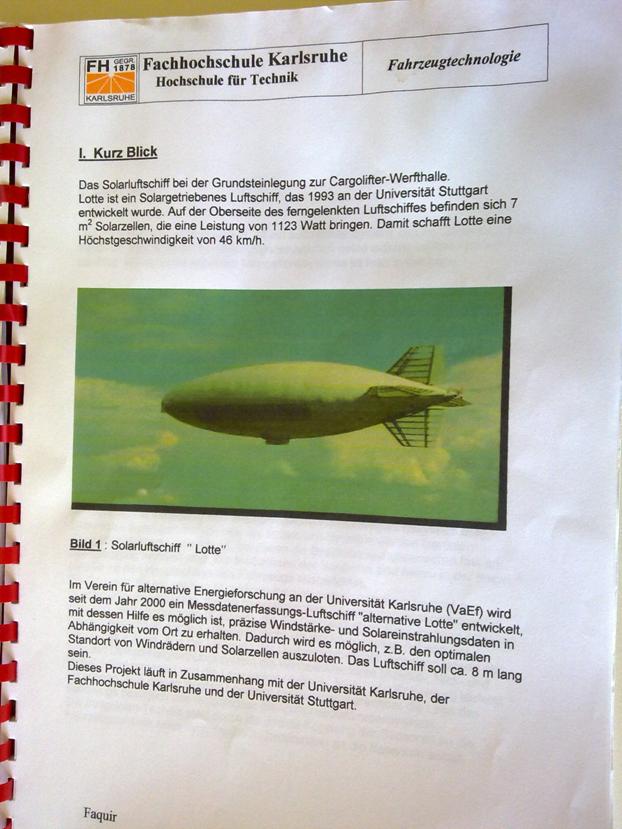

Airships are becoming more and more important within

the last years. At the Institut für Statik und Dynamik der Luft- und

Raumfahrtkonstruktion at the University

of Stuttgart a solar

airship was built. In February 1992 the project Solarluftboot was initiated.

The purpose of this project was to find new materials, new construction methods

and a new concept for controlling and navigating an airship run by a solar

energy engine.

The alternative Lotte a cooperation project

between the universities of Karlsruhe and Stuttgart and the

Fachhochschule Karlsruhe - is planned to be an experimental airship which can

be controlled directly from the ground (first step of implementation) or

(second step of implementation) fly automatically to specified coordinates. The

energy supply is going to be conventional batteries in the first step but it is

planned to switch to solar energy later. With alternative Lotte environmental

data are collected during the flight via different sensors which can be mounted

on the airship. In the first step the speed of the wind, the temperature and the

solar radiation are measured. Apart from that flight data such as acceleration,

angular velocity and azimuth angle are measured for navigation purposes.

For the

above mentioned Solarluftschiff an alternative flight control system (flight

control system - FCS) is developed, which takes into account modern information

technology methods.

The

"alternative LOTTE" project is lead by the association VaEF e.V. As

cooperation main cooperation partners act the Universities of Karlsruhe and Stuttgart. The

"alternative LOTTE" project intends to use an airship for taking wind

measurement data.

Personal

costs: About 3 man years

Material

costs: 6000 EUR

Renting

rooms, computers etc. 10 000 EUR

The project

was undergone through student research works (mostly master thesises).

This Flight Control System is based on the IFR

Control System of the Lotte airship of the University

of Stuttgart

/ Germany

This Flight Control System is based on the IFR

Control System of the Lotte airship of the University

of Stuttgart

/ Germany

Based on:

Samir

Mourad, Diplomarbeit (Master

Thesis)Anbindung des Echtzeitbetriebssystems VxWorks an die Middleware OSA+

und Integration dessen in eine dienstorientierte

Test-Echtzeitsystem-Umgebung"

Institut für

Mikrorechner und Automation, Univ. Karlsruhe, Supervisor: Prof. Dr. U.

Brinkschulte, Institut für Prozessrechnentechnik und Robotik, Faculty of Computer Science, Universität Karlsruhe (TH),

December 2000

Überblick

1. Einleitung

Allgemeingehaltene

Einführung in den Aufbau von Echtzeitsystemen. Anforderungen an heutige

Echtzeitsysteme: Rechtzeitigkeit der Verarbeitung, wiederverwendbarer Aufbau

des Gesamtsystems. Mögliche Lösung: dienstorientierter Aufbau (modular,

einfache Erweiterbarkeit des Echtzeitsystems, gibt natürlich den funktionalen

Ablauf bei einem Echtzeitsystem wieder) mit Middleware (Trennung von

Anwendungssoftware und Betriebssystem bzw. Hardware)

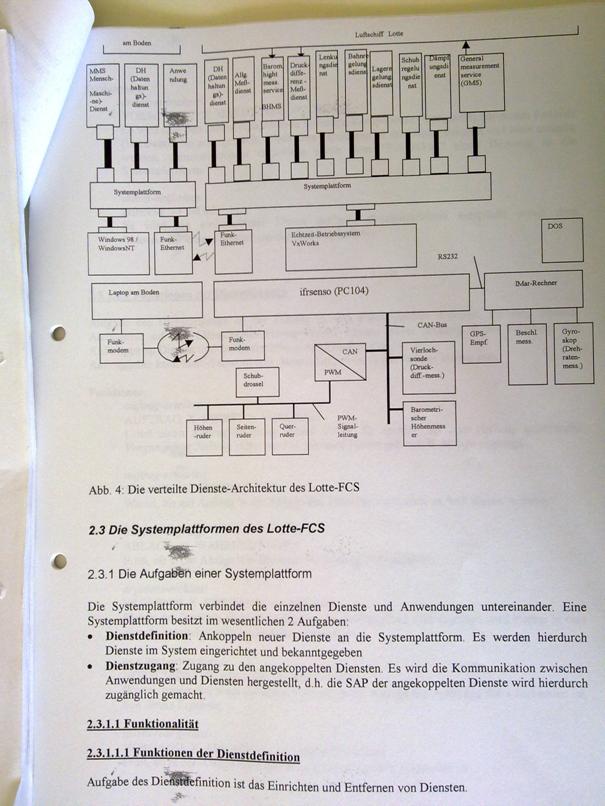

2. Aufgabenstellung

und Lösungsansatz

2.1 Aufgabe

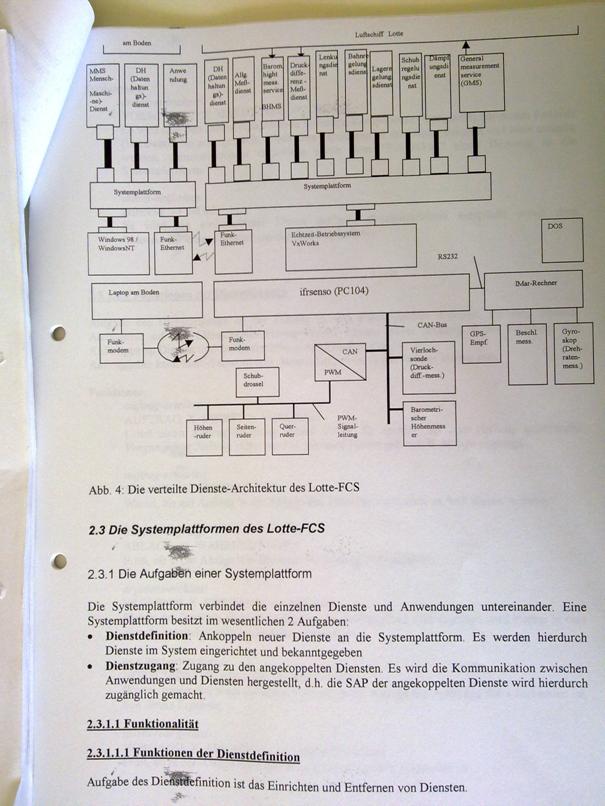

Erstellung eines

dienstorientierten Test-Echtzeitsystem mit zwei Rechnern, die mit Funk-Ethernet

verbunden sind. Der zweite Rechner hat einen CAN-Bus, an dem Sensoren und

Aktoren hängen. Über Funkethernet gibt der erste Rechner dem zweiten Rechner

Anweisungen bezüglich der Bedienung der Sensoren und Aktoren. In die andere

Richtung werden Meßdaten übertragen und auf einer Oberfläche des ersten

Rechners dargestellt.

2.2 Vorstellung

einiger vorhandener Systeme

2.2 Lösungsansatz

dienstorientierter

Systemaufbau (siehe entsprechende Abbildung in Lottefcs_vom_Leptop.doc)

Begründung für die

Auswahl von VxWorks: relativ einfache Handhabbarkeit wegen umfangreicher Entwicklungsumgebung,

in der Praxis erprobtes Standard-RTOS.

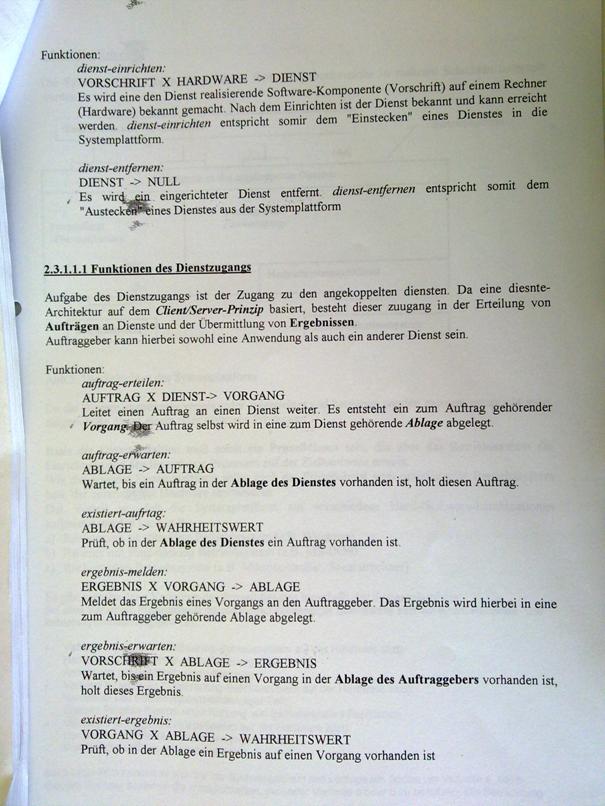

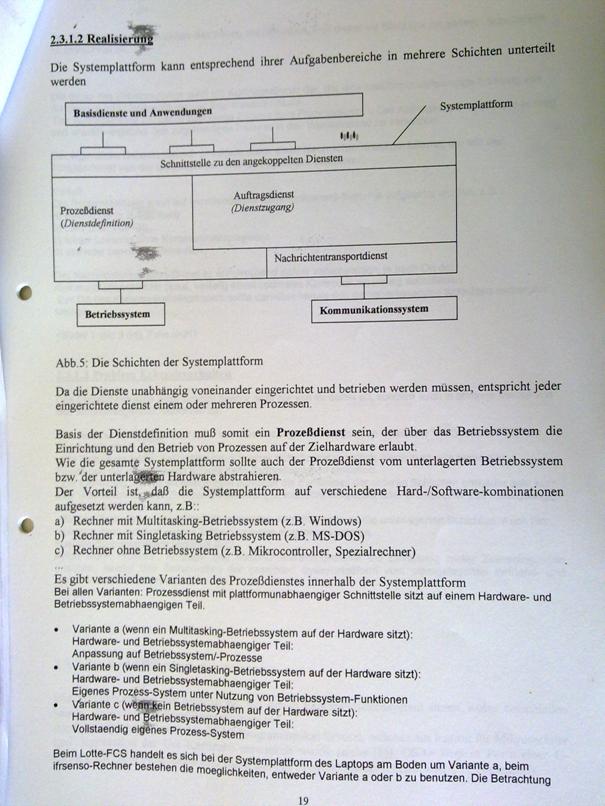

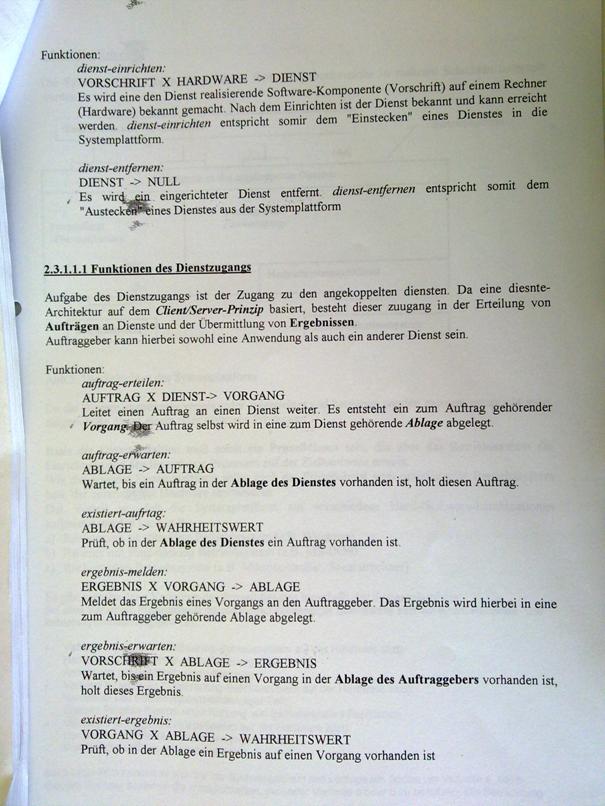

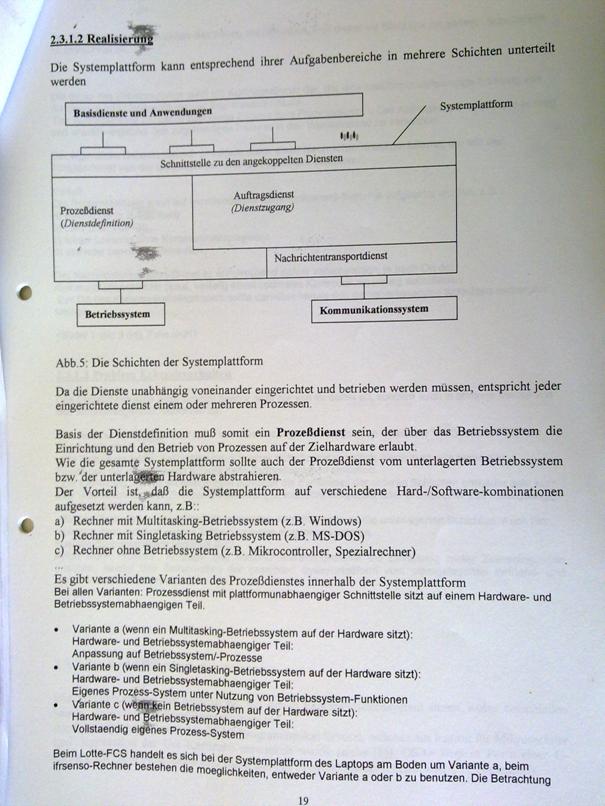

3. OSA+

Beschreibung von

Prozeßdienst, Ereignisdienst (SA von Sven), Kommunikationsdienst und

Datenhaltungsdienst (Zusammenfassung aus

Institutsbericht)

4. VxWorks

Vorstellung des Basic

OS, des I/O System, des lokalen

Filesystems und des Kommunikationssystems (Zusammenfassung aus Programmer's

Guide)

5. Anpassung von

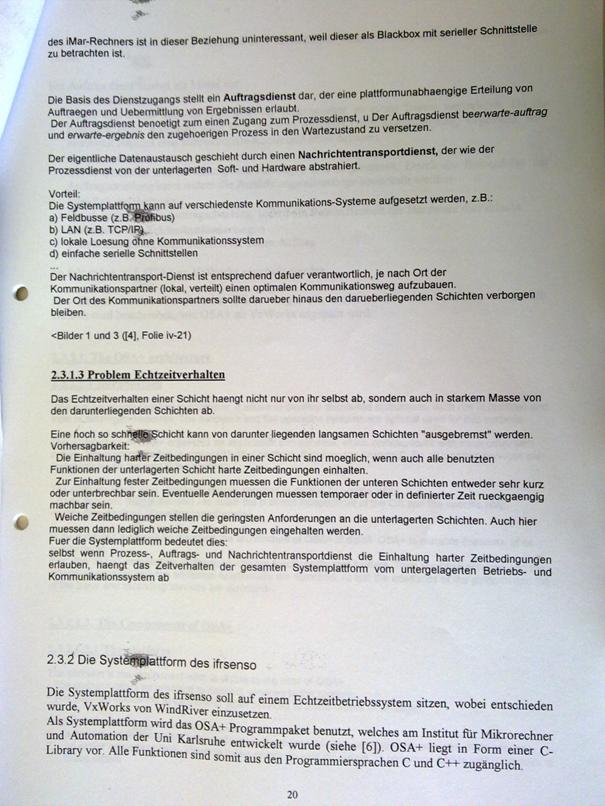

VxWorks an OSA+

5.1 Prozeßdienst

5.2 Ereignisdienst (SA

von Sven)

5.3

Kommunikationsdienst

6. Integration ins

Gesamtsystem

Beschreibung der

Dienste, der Treiber, der HW und des Zusammenspiels des Gesamtsystem

6.1 Oberfläche des 1.

Rechners und zugehörige Dienste

6.2

Kommunikationsdienst zwischen 1. und 2. Rechner

6.3 Meßdienste und

Stelldienste auf 2. Rechner

6.4 Treiber für VxWorks

bzgl. CAN-Bus (DA von M. Subhan)

(6.5 Sensoren/Aktoren

auf dem CAN-Bus)

7. Ausblick

Variierungsmöglickeiten:

Ersetzung der Sensoren/Aktoren, Austausch des VxWorks durch ein anderes RTOS

bzw. direkte Anbindung an die HW, Ersetzung des Funkethernet durch ein anderes

Protokoll.

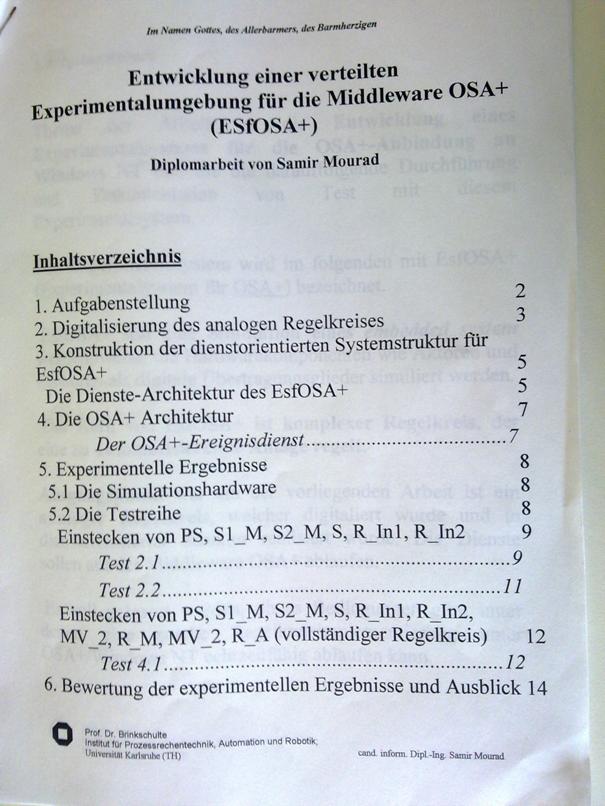

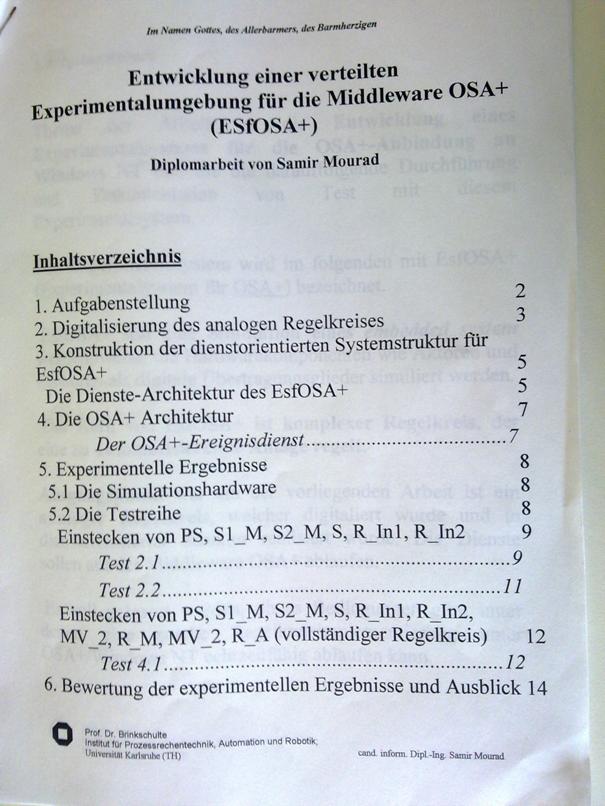

Entwicklung einer

verteilten

Experimentalumgebung fuer

die Middleware OSA+

(ESfOSA+)

Diplomarbeit von Samir

Mourad

(Inhaltsverzeichnis)

1. Aufgabenstellung

Thema der Arbeit ist die Entwicklung eines Experimentalsystems

fuer die OSA+-Anbindung an Windows NT und die die darauffolgende

Durchfuehrung und Dokumentation von Test mit diesem Experimentalsystem.

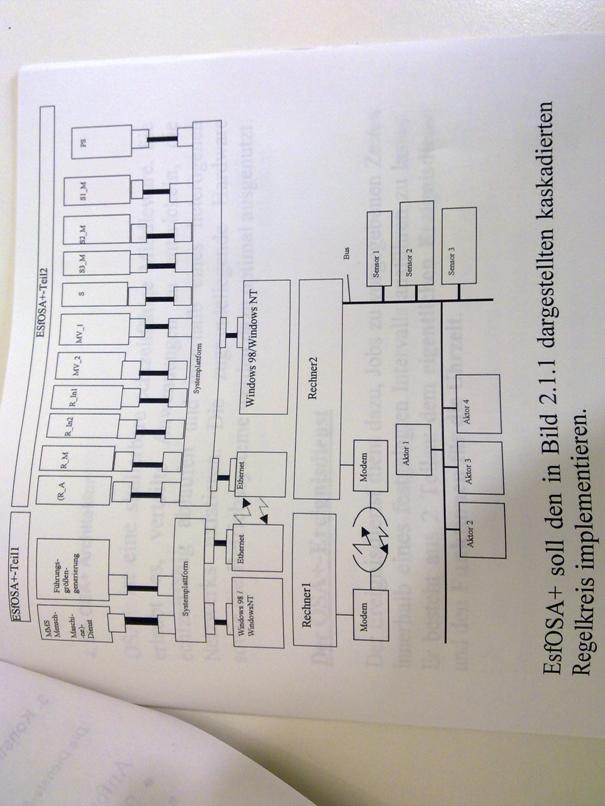

Das Experimentalsystem wird im folgenden mit EsfOSA+

(Experimentalsystem fuer OSA+) bezeichnet.

EsfOSA+ soll eine Simaulation eines embedded system

werden, wobei die Hardwarekomponenten wie Aktoren und Sensoren als digitale

Uebertragungsglieder simuliert werden.

]Der Kern von EsfOSA+ ist komplexer

Regelkreis, der eine zu automatisierende Anlage regelt.

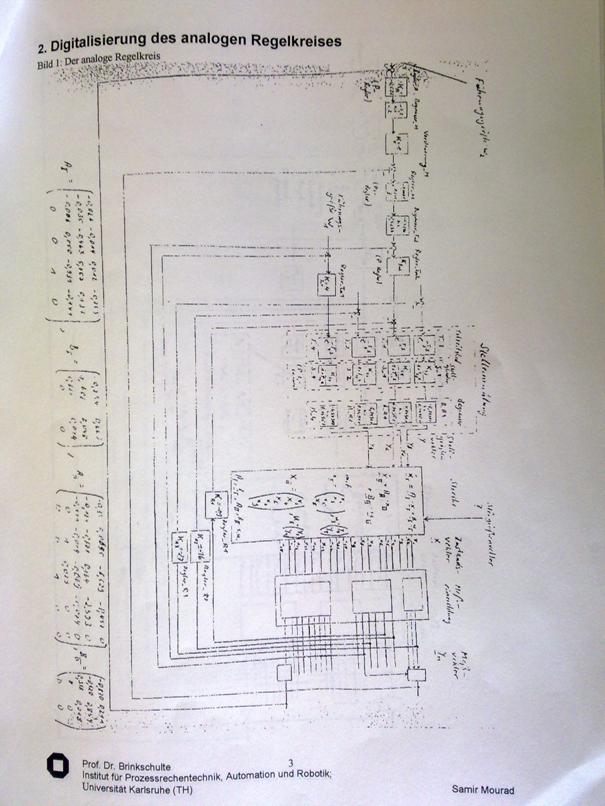

Ausgangspunkt war ein der vorliegenden Arbeit ist

ein analoger Regelkreis, welcher digitaliert wurde und in

dienstorientierter Struktur realisiert wurde. Die Dienste sollen auf der

Middleware OSA+ ablaufen.

Es soll getestet warden, ob es Bedingungen

gibt, unter denen eine solche Regelkreisimplementierung unter OSA+/Windows NT

echtzeitfaehig ablaufen kann.

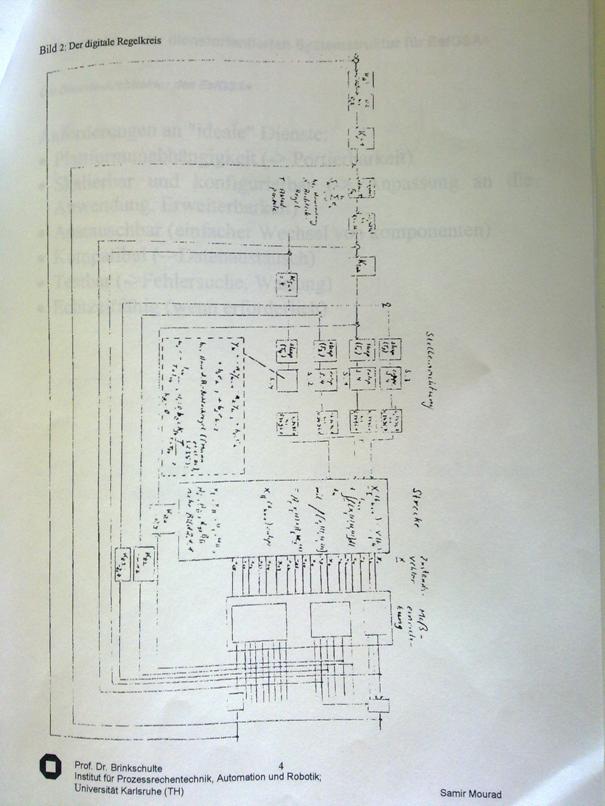

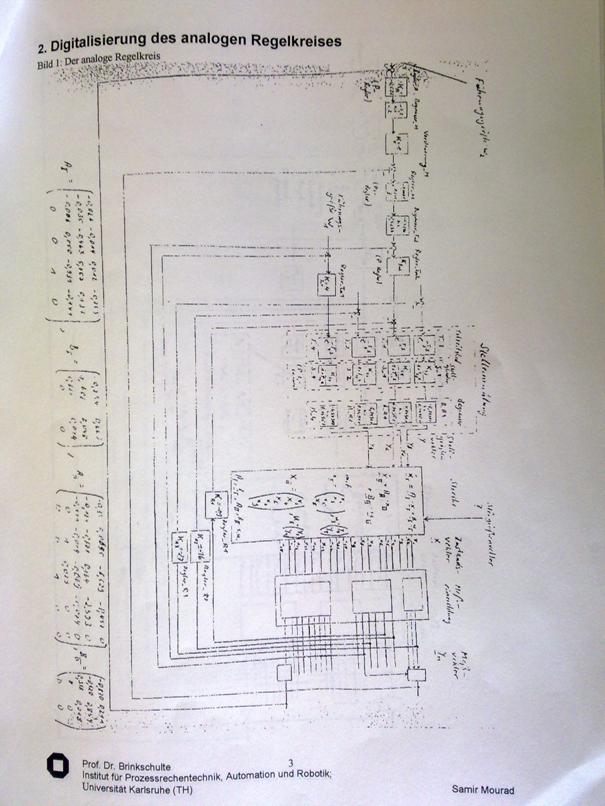

2. Digitalisierung des analogen Regelkreises

Bild 1: Der analoge Regelkreis

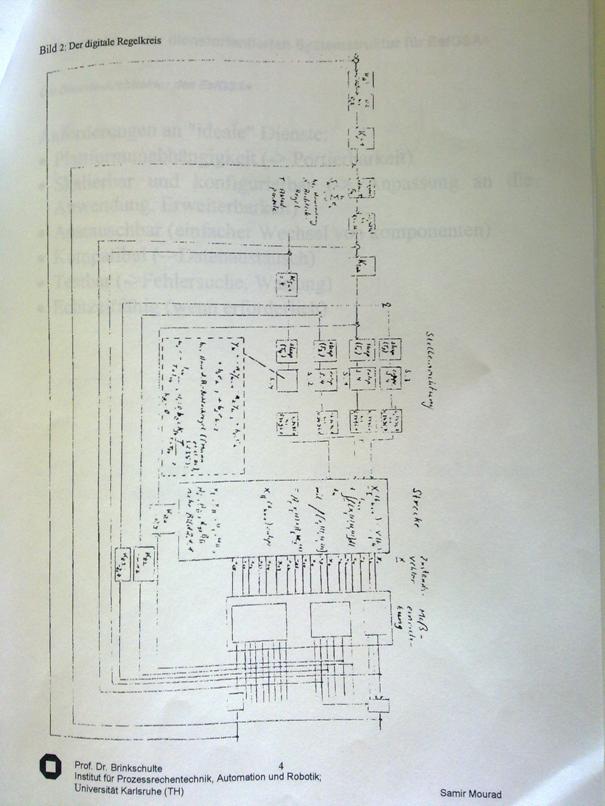

Bild 2: Der digitale Regelkreis

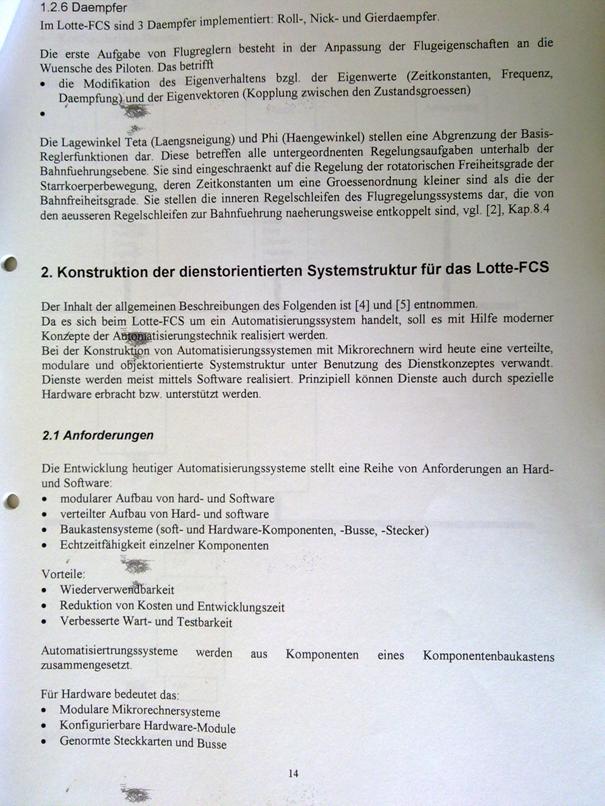

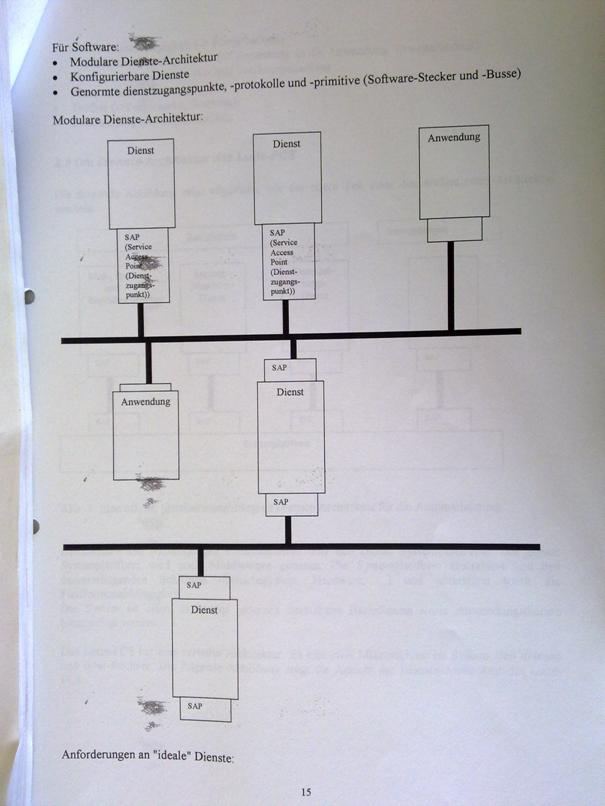

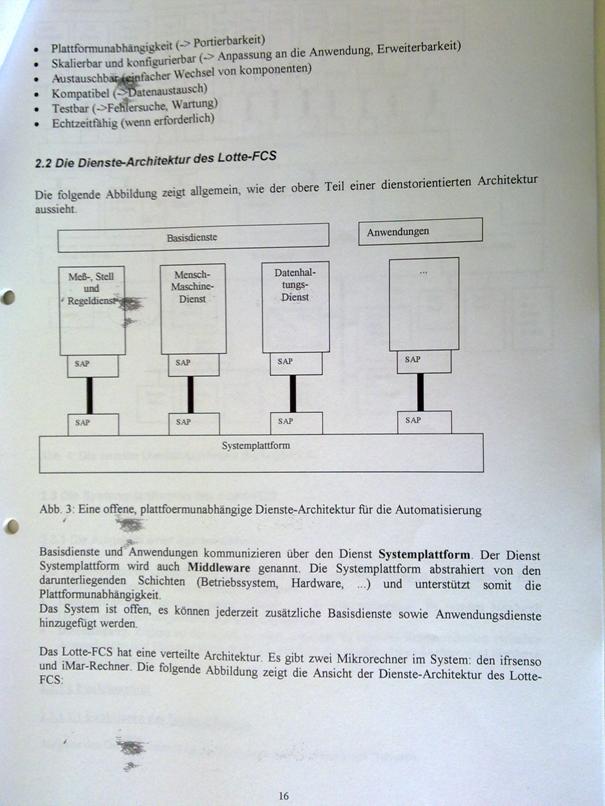

3. Konstruktion der dienstorientierten Systemstruktur

fuer EsfOSA+

Die Dienste-Architektur des EsfOSA+

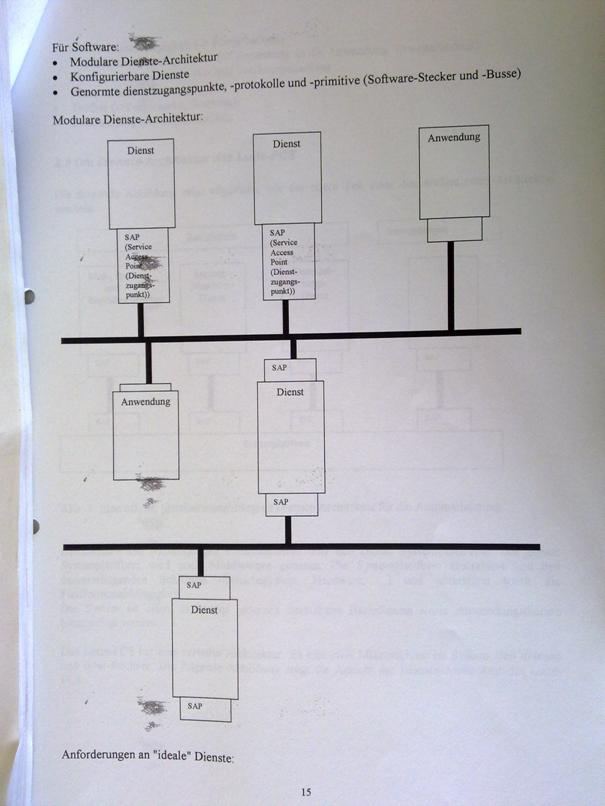

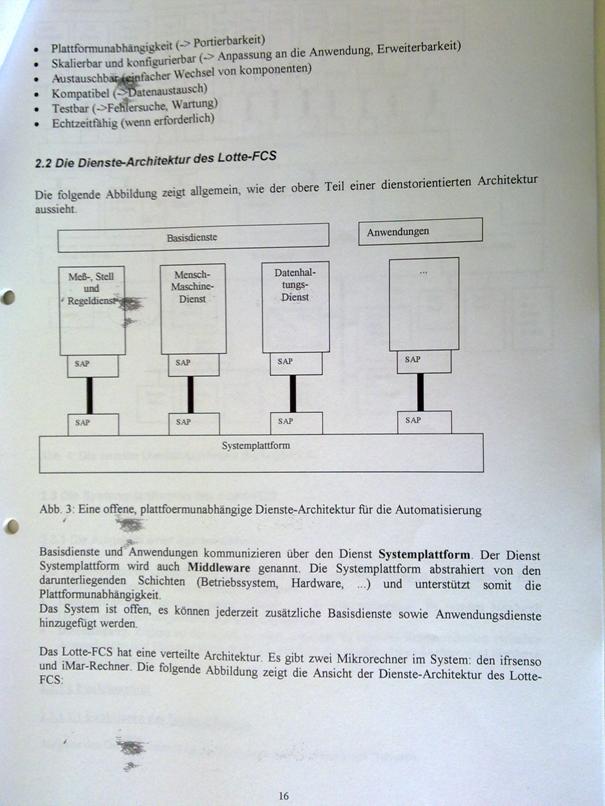

Anforderungen an "ideale" Dienste:

* Plattformunabhaengigkeit (-> Portierbarkeit)

*Skalierbar und

Konfigurierbar (-> Anpassung an die Anwendung, Erweiterbarkeit)

* Austauschbar (einfacher Wechsel von Komponenten)

* Kompatibel (->Datenaustausch)

* Testbar (->Fehlehrsuche, Wartung)

* Echtzeitfaehig (Wenn erforderlich)

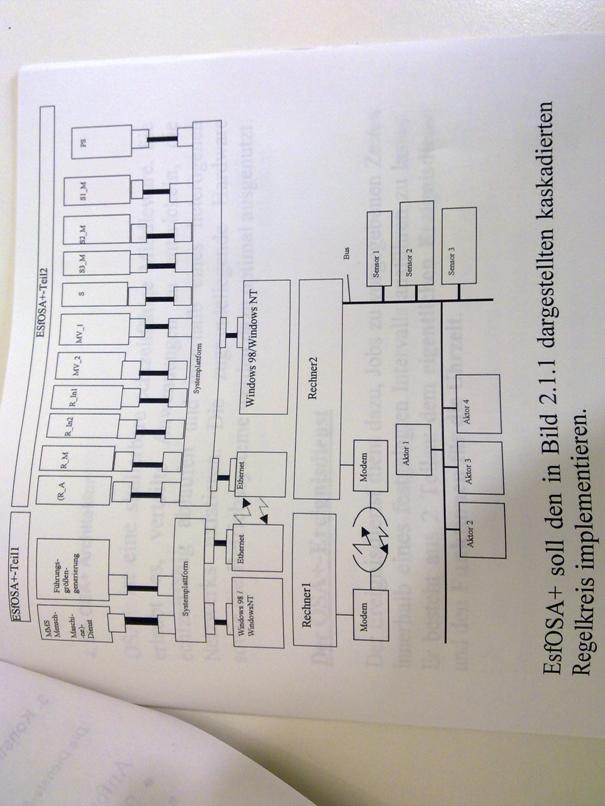

EsfOSA+ soll den in Bild 2.1.1 dargestellten

Kaskadierten Regelkreis implementieren.

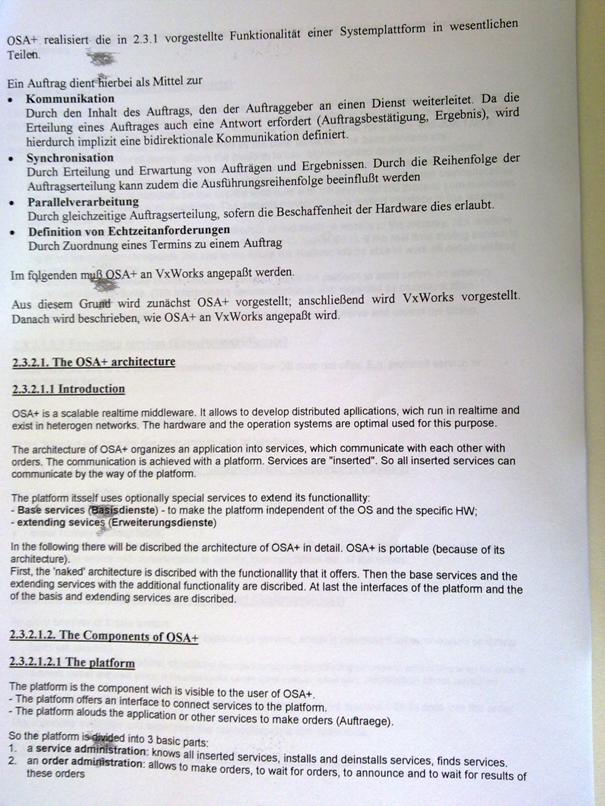

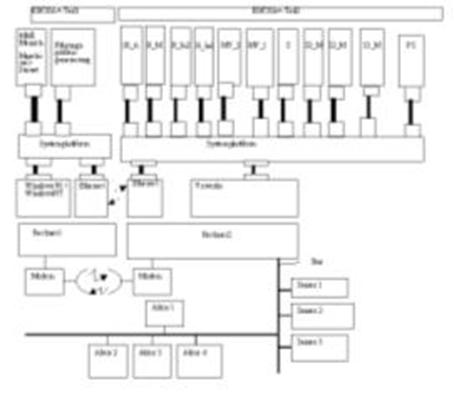

4. Die OSA+ Architektur

OSA+ ist eine skalierbare echtzeitfaehige Middleware.

Sie erlaubt es, verteilte Anwendungen zu entwickeln, die echtzeitfaehig

ablaufen und innerhalb eines heterogenen Netzwerks existieren. Die

zugrundeliegende Hardware sowie die Betriebssysteme warden dazu optimal ausgenutzt.

Der OSA+-Ereignisdienst

Der Ereignisdienst dient dazu, Jobs zu vorgegebenen

Zeiten innerhalb eines festgelegten Intervalls ausfuehren zu lassen. Er besteht

aus 2 Teilen: dem eigentlichen Ereignisdienst und den Funktionen fuer

die Uhrzeit.

5. Experimentelle Ergebnisse

5.1 Die

Simulationshardware

Die Simulation life auf einem PC mit einem Intel

Pentium Prozessor mit 133 MHz und 32 MB RAM ab.

Sensorik und Aktorik wurden softwaremaessig simuliert.

Es war keinerlei reale Sensorik oder Aktorik angeschlossen.

5.2 Die

Testreihe

Bei den Tests wurden verschiedene Dienste eingesteckt

und das Zusammenspiel getestet. Dabei wurde so vorgegangen, dass zunaechst nur

die Dienste der inneren Regelschleifen mit den zugehoerigen Messdiensten und

natuerlich der Streckensimulation und des Stelldienstes eingesteckt wurden.

Spaeter wird sukzessive der ganze kaskadierte Regelkreis von innen nach aussen

aufgebaut.

Einstecken von

PS, S1_M, S2_M, S, R_In1, R_In2

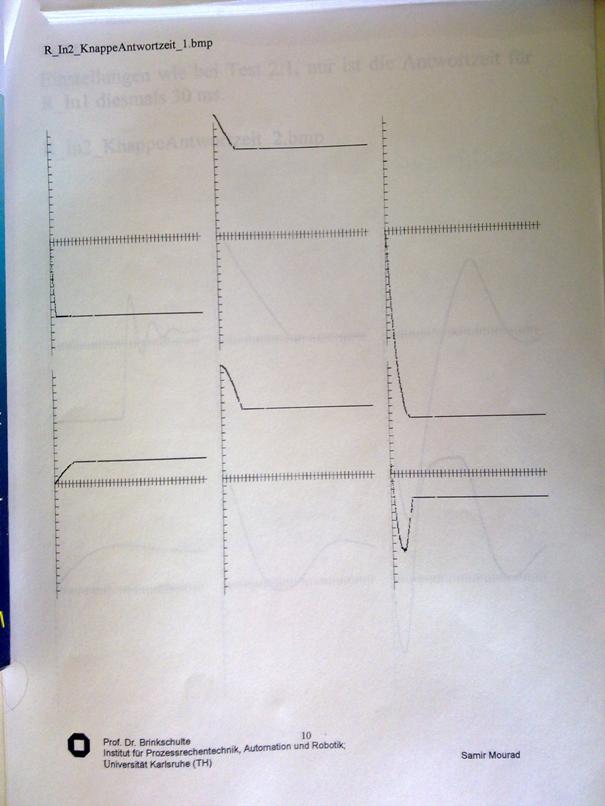

Test 2.1

Festlegung der max. Antwortzeiten der einzelnen Dienste

(durch den Ereignesdienst)

PS 10ms

R_In1 20ms

R_In2 100ms

Wie schon im vorigen Test warden einige Groessen ueber

der Zeit aufgezeichnet (Graphen von links nach rechts):

y_4, x_1,

x_5, x_12, x_8, y_1,, (d.h. der 1.

Graph v. l. zeigt y_4, der 2. Graph v. l. zeigt x_1 usw.)

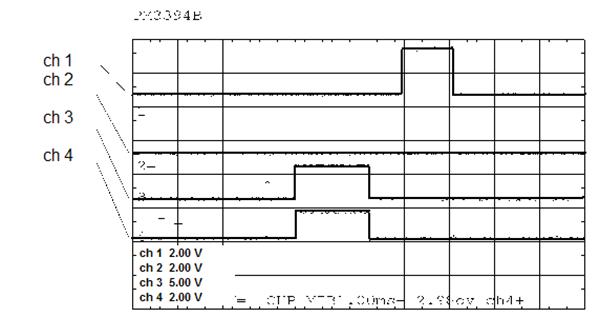

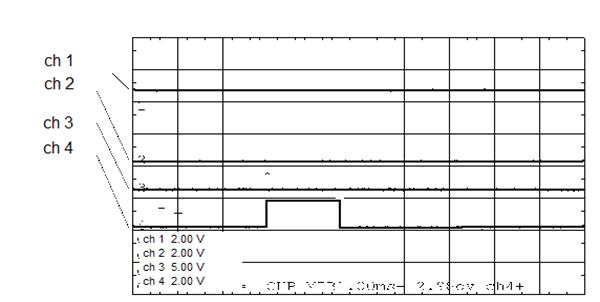

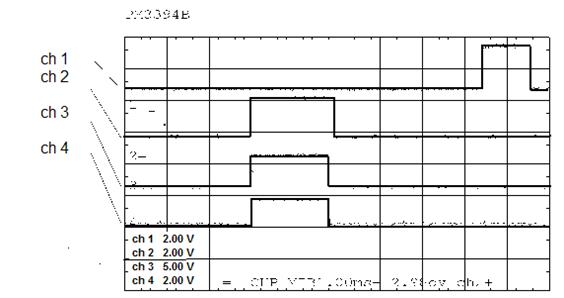

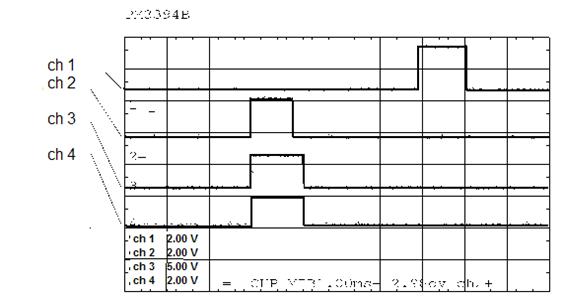

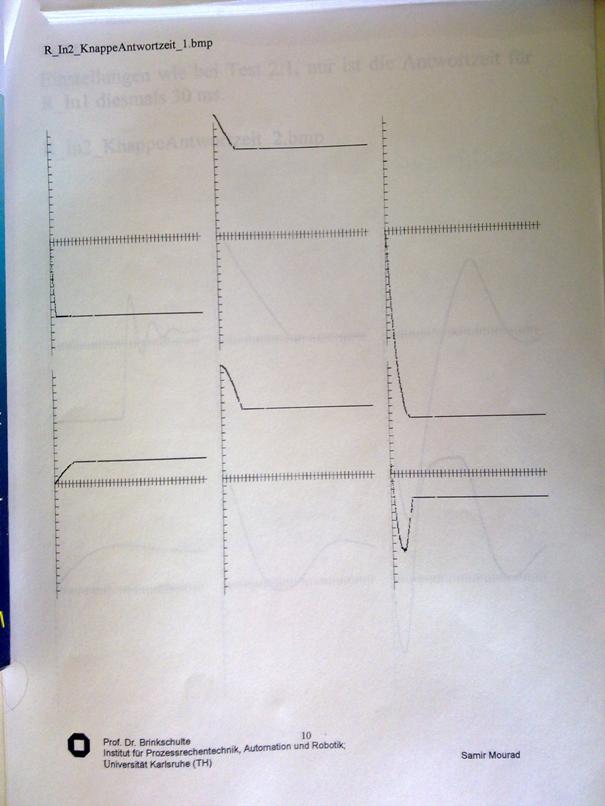

Im Bild R_In2_KnappeAntwortzeit_1.bmp ist zu sehen,

dass die Dienste nicht vollstaendig ausgefuehrt warden konnten. Im naechsten

Versuch (siehe R_In2_KnappeAntwortzeit_2.bmp) wird daher die Antwortzeit fuer

R_In1 erhoeht.

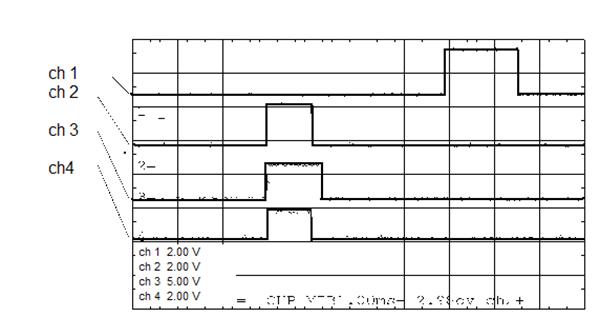

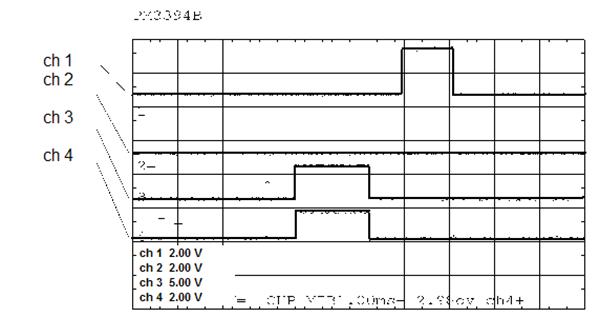

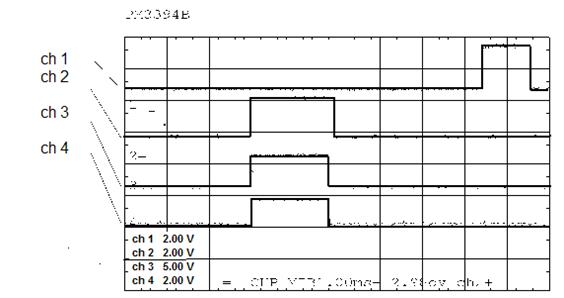

R_In2_KnappeAntwortzeit_1.bmp

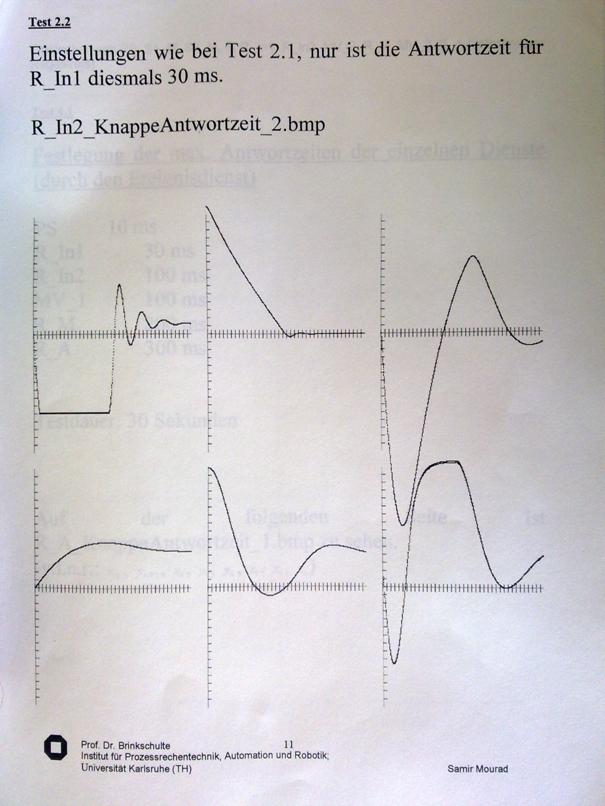

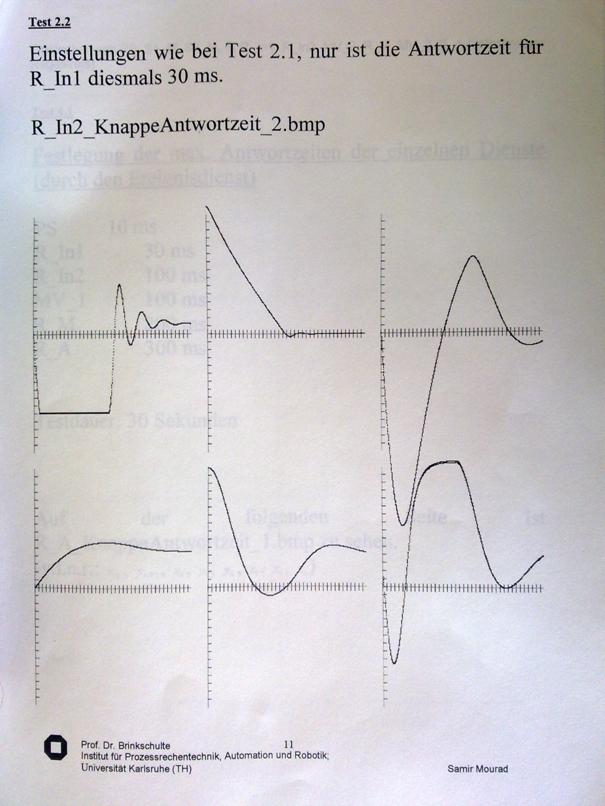

Test 2.2

Einstellungen wie bei Test 2.1, nur ist die

Antwortzeit fuer R_In1 diesmals 30 ms.

R_In2_KnappeAntwortzeit_2.bmp

Einstecken von

PS, S1_M, S2_M, S, R_In1, R_In2, MV,_2, R_M, MV_2, R_A (vollstaendiger

Regelkreis)

Test 4.1

Festlegung der max. Antwortzeiten der einzelnen

Dienste (durch den Ereignisdienst)

PS 10 ms

R_In1 30 ms

R_In2 100 ms

MV_1 100 ms

R_M 200 ms

R_A 300 ms

Testdauer: 30 Sekunden

Auf der folgenden Seite ist

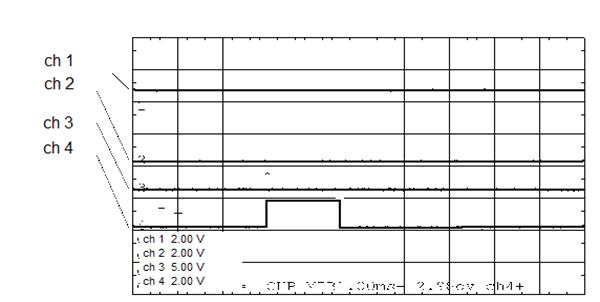

R_A_KnappeAntwortzeit_1.bmp zu sehen.

(v.l.n.r.: x_12, y_MV1, x_8, y_1, y_4, x_1, x_3,

x_5)

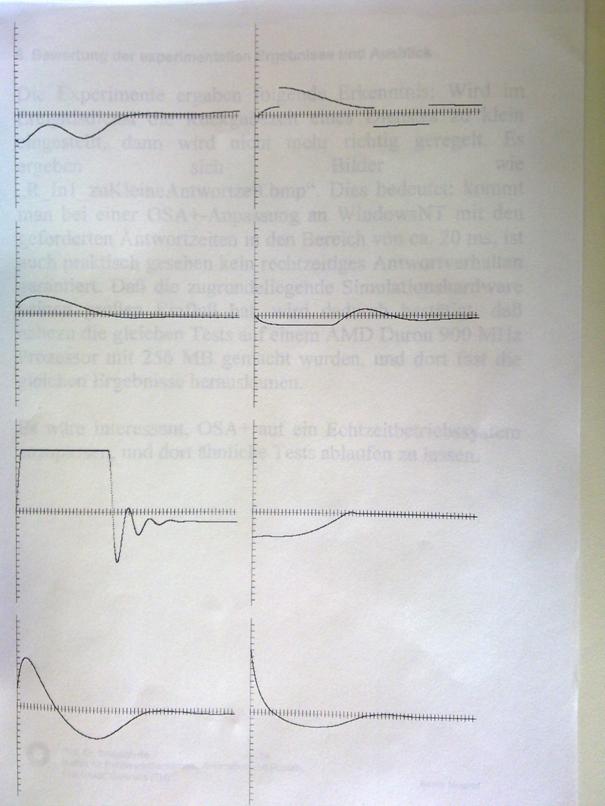

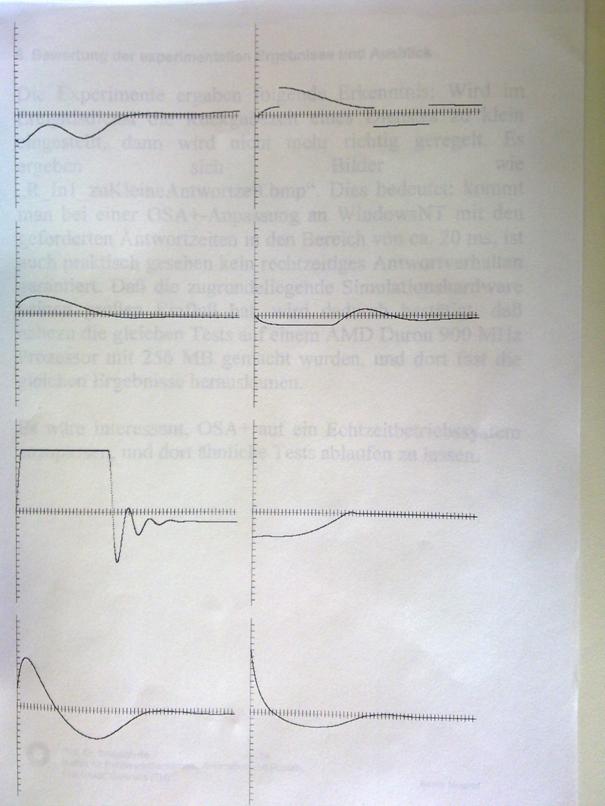

6. Bewertung der experimentellen Ergebnisse und

Ausblick

Die Experimente ergaben folgende Erkenntnis: Wird im

Ereignisdienst die Rueckgabezeit eines Dienstes zu klein eingestellt, dann wird

nicht mehr richtig gereglt. Es ergeben sich Bilder wie

"R_In1_zuKleineAntwortzeit.bmp". Dies bedeutet: kommt man bei einer

OSA+-Anpassung an WindowsNT mit den geforderten Antwortzeiten in den Bereich

von ca. 20 ms, ist auch praktisch gesehen kein rechtzeitiges Antwortverhalten

garantiert. Dass die zugrundeliegende Simulationshardware keinen grossen Einfluss

hat, wird dadurch bestaetigt, dass nahezu die gleichen Tests auf einem AMD

Duron 900 MHz Prozessor mit 256 MB gemacht wurden, und dort fast die gleichen

Ergebnisse herauskamen.

Es waere interessant, OSA+ auf ein

Echtzeitbetriebssystem anzupassen, und dort aehnliche Tests ablaufen zu lassen.

Based on Entwicklung des Ereignisdienstes

für die Middleware OSA+, Studienarbeit von Sven Forstmann, 2001

Studienarbeit

(Bachelor Thesis)

of

Sven

Forstmann

27 Sep 2001

Institute for

Prozeßrechentechnik and automation, Univ. Karlsruhe

Supervisors:

Samir Mourad

Dipl. -Inform. Jens

Riemschneider

Prof. Dr. Uwe Brinkschulte

1 Abridged

Version. 4

2 The nature of

the task. 4

3 The OSA+

architecture. 4

3.1 Introduction. 5

3.2 The components of OSA+. 6

3.2.1... The Platform.. 6

3.2.2... Generic Services. 7

4 Components of

the OSA Eventing service. 8

4.1 The time functions. 8

4.1.1... The handling of the time. 8

4.1.2... Initialization. 9

4.1.3... Functions for time management 10

4.1.3.1 Time

Continued. 10

4.1.3.2 Reading

Time. 11

4.1.3.3 Move

Time. 11

4.1.3.4 Spend

time in a string. 11

4.2 The event service. 12

4.2.1... General Information. 12

4.2.2... The initialization of the Ereignisdienstes. 14

4.2.3... Features of the Ereignisdienstes. 14

4.2.3.1 Add

an Event 14

4.2.3.2 Remove

a Events. 15

4.2.3.3 Reading

a result/error codes. 15

5 Short Overview.. 16

5.1 Time functions/variables. 16

5.2 Features of the Ereignisdienstes. 16

6 Configuration. 16

7 Theory of

Operation. 17

7.1 Osagettime() 17

7.2 Osasettime(int,int) 17

7.3 Osaaddtime(int,int) 18

7.4 Char * osaPrintTime( int, int ) 18

7.5 Osainitevents() 18

7.6 Int osaAddEvent(uint,uint, uint, uint,uint, uint,uint,

uint, function) 18

7.7 Int osaDelEvent(uint,uint,uint,UINT) 20

7.8 OSA_Error osaGetEventResult(uint,UINT) 20

7.9 Internal functions of the

Ereignisdienstes. 21

8 Programming

examples. 21

8.1 For example: Changing the Time. 21

8.2 Example: Add an Event 22

8.2.1... Start a

function at a specified time. 22

8.2.2... Repeated start a function. 23

8.3 Queries of results. 23

8.4 Delete a Events. 24

9 Test Runs. 25

9.1 Deliver-Test 26

9.2 Test run of a cyclical events with

open. 27

9.3 Test the maximum temporal resolution

on different systems. 28

9.3.1... System 1. 28

9.3.2... System 2. 30

9.3.3... System 3. 32

9.4 Stability tests. 34

9.4.1... Exceeding the

maximum acceptable number of Events. 34

9.4.2... Exceeding the

maximum acceptable number of events per unit time. 34

9.4.3... Overrun of the

events per unit time through Zeituberschneidung. 35

10 Results and

Outlook. 37

11 ANNEX.. 38

11.1 List of all Windowsspezifischen

Functions. 38

12 Literature. 38

Declaration

I hereby declare, Sven Forstmann, that I have carried

out this work independently.

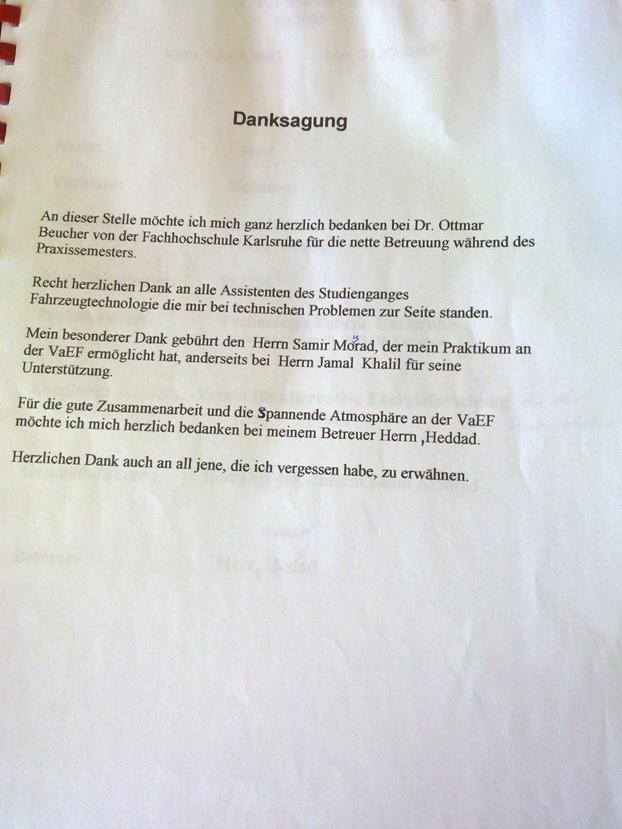

Thanksgiving

First of all, I wish to thank Prof. Brinkschulte for

the nice assistance and cooperation and also thank Jens Riemschneider for

assistance during the incorporation in OSA+. Samir Mourad was for the friendly

help thanked in advance of the thesis.

Middleware systems support the development of

real-time systems especially in heterogeneous environments, in the present work

is the event service with all the details, as well as the

Implementationsbeschreibung presented.

The event service extends the existing OSA+ to

services for the timed start jobs or functions, as well as to several functions

to manage the time.

What is important is that the Ereignisdienstes the

OSA+ now one step closer in the direction of the real-time capability brings,

this is achieved by, inter alia, that when you start a job / a function also

can be specified, in which interval This is to be started, however, the extent

to which this real-time capability achieved will depend on the respective

operating system, and is also by the handling of the time functions of the same

limited.

In the framework of a joint project with several

industrial partners, the Institute for Prozeßrechentechnik and Automation the

open, scalable, and real-time middleware platform OSA+ (Open System

Architecture Platform for universal services) developed, today's real-time

systems usually operate in environments with many asynchronous events, and the

processing of these events is often complex and may, by the introduction of a

own service established for this purpose will be much easier. The aim of this

thesis is the design of the service, a prototypical implementation and

integration into the OSA+ overall architecture.

The content of this chapter is [Brinks et al, 00] taken

from the description of the individual OSA+ -functions from [Brinks et al, 00]

are not listed, it can be read there.

OSA+ is a scalable real-time middleware that allows to

develop distributed applications, the real timable expire and exist within

a heterogeneous network. The underlying hardware, as well as the operating

systems to be used optimally.

The architecture of OSA+ is divided by a application

in services that communicate with each other on jobs, this communication is

achieved by means of a platform, in which services in the platform

"Plugged in", in this way can inserted into all services with one

another using the Platform communicate.

The platform itself specifically used excellent

services, to increase its capabilities, including generic services, which

ensure that the platform independent of the operating system and the underlying

hardware, it is, as well as Erweiterungsdienste, the specific tasks for the

platform provide the platform is, however, also run without these services.

The following is the detailed architecture described

by the OSA+.

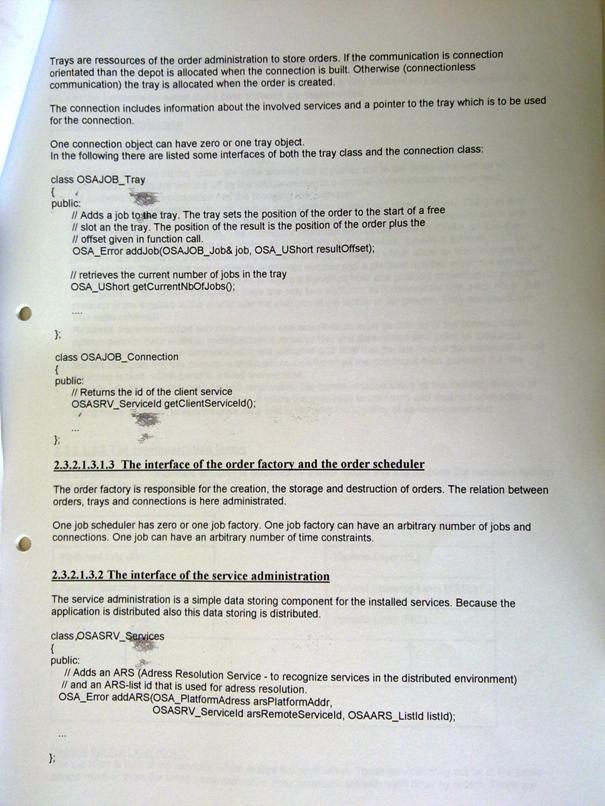

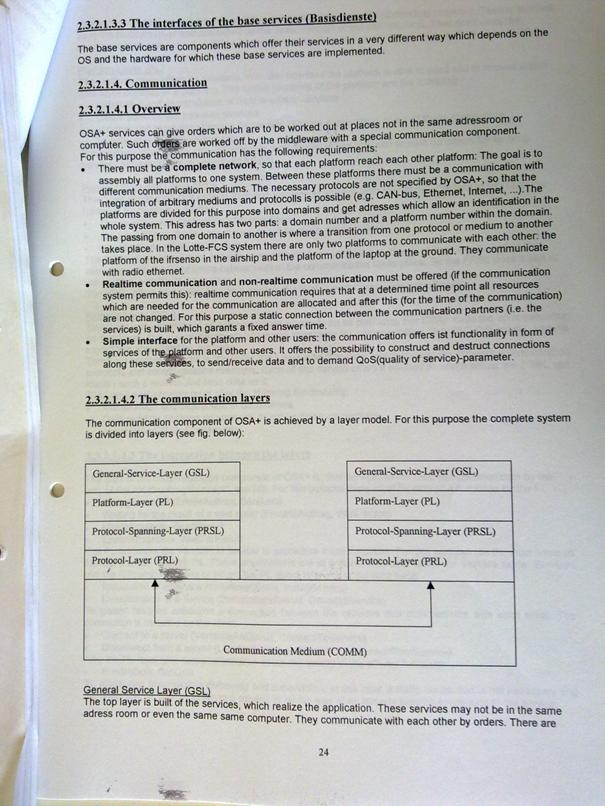

1: OSA+ architecture

2:

Communication of services using job and outcome ( =job)

First, it is described as the "naked"

platform looks like and what functionality it provides, so that you will be the

base and Erweiterungsdienste explains and the associated additional

possibilities, thus acquires the the platform, and concludes the interfaces of

the platform and the basic and Erweiterungdienste described.

The platform is the component to the user by the OSA+

is visible, it offers a interface, with whose assistance services in the

platform can be inserted and allowed the grant of orders, which is divided the

platform in three basic parts:

·

A Service Management:

she knows all inserted services and completed the install and

uninstall services, as well as locate of services;

·

A job

management: Allows the give and expect of orders and the report of

results of this and expect orders;

·

A user

interface: Is there a clear struktierte the user interface to

these two bodies.

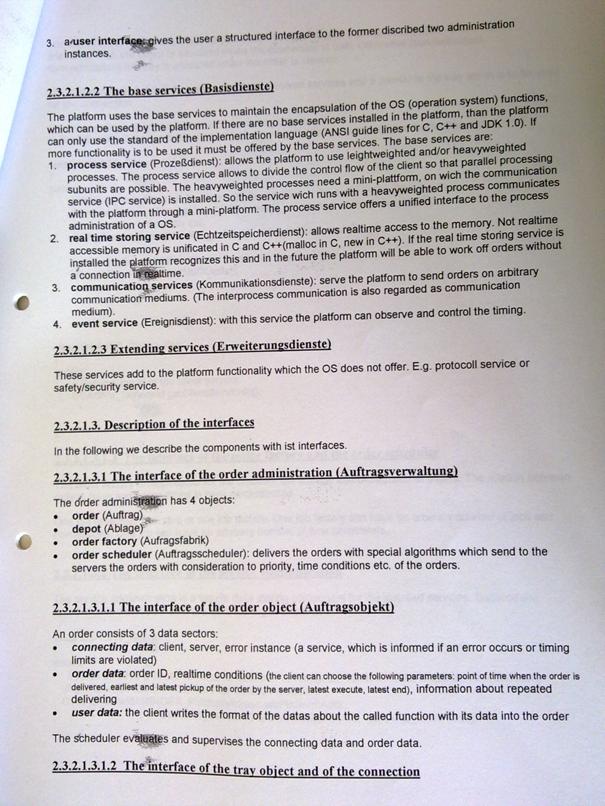

The platform uses the generic services, to an

encapsulation of the operating system functions, which you can use for your

tasks are not generic services installed in the platform, so must the platform

without these features and can only get to make, what as a recognized standard

of the underlying implementation language is recognized, based on the

ANSI-Richtlilien for C and C++ or the JDK 1.0 . Beyond functionality of the

generic services must be available in each are this:

·

Prozeßdienst: it allows the

platform lightweight and/or heavyweight to take advantage of services, he

provides a unified interface to process administration of the operating system,

and the OSA+ -Prozeßdienst allows it, split the control flow of the customer,

so that the contractor and the customer (quasi) in parallel, each with their

Arbeitfortfahren can. This is possible, that of the Prozeßdienst the platform

allowed, with a service to connect a Control Flow, heavyweight Kontrollflusse

are situated in their own space and are in need of a Miniplattform, on the A

Kmmunikationsdienst (IPC-service) is installed.

·

Echtzeitspeicherdienst: it allows the

realtime access to memory (in particular the allocation and release), not

real-time memory is in the above language specifications standardized (e.g.

malloc in C or new in C++ or Java). The service is not installed, so the time

conditions are checked only a job, but not guaranteed.

·

Communications services: serve the platform

to the shipping of orders over any communication media, it is also the

Interprocess Communication as a means of communication.

·

Eventing service: is the

platform for the monitoring and control of temporal processes. He provides

specific Auftragspezielle jobs to the platform, so this on certain events can

be informed.

The event service is divided into the services for the

management of the time, as well as in the of the actual Ereignisdienstes. a

separation of these two is not impossible, but awkward, as the event service on

the functions of the time is dependent on time, to all the processes to start.

In the event service is managed the time in the UNIX

FORMAT, as this is the easiest to handle, and at the same time the

implementation on UNIX/LINUX - systems much easier.

In this format, the seconds since 1.1.1970 12:00:00 in

a 32 ( soon, perhaps even 64 ) bit - value paid, which means that extra for

Sekunde/Minute/Stunde/ ... not a variable is needed, and also that the invoices

are carried out with the time, are now almost easily.

In the OSA-event Service is the time but now not only

in a 32-bit value, since there often also in real-time applications to a higher

accuracy is essential, therefore it is in addition to the 32-bit variables for

the seconds a further variable used for the milliseconds. This makes it

difficult and slows down while the calculation of time differences, but it is

for the time-exactly timed execution of the job is essential.

It could also have been upgrading the CMOS-clock for

all of the operations of the time, as well as to use of the Ereignisdienstes -

this had caused some complications, however, first of all it is not accurate

enough, because you only on the time the tenth stores, since the event service

is to be real timable and there you have a accuracy is promoted in the

millisecond range, this is enough and not from, a further difficulty is that

when the time change this change affects the entire system and be influenced by

other programs, then what in these can create incorrect results.

3: Structure of the time

4:

Integration of time management, and in the system of the Ereignisdienstes

Before the time functions that can be called the

initialization must be performed first, which for the time periods

required calculated variables.

This calculation is necessary, because the time with

the help of two different functions is calculated.

With the A

is initially read out the time of the system and stored in the time variable,

since the system time but only on the second exactly is returned, only to a

Sekundenwechsel must be serviced to ensure the Millisekundenanteil can be

initialized with zero.

Now, the difference to the value of the other function

are calculated, which returns the system time in Millisekundenformat. In this

is the number of milliseconds since the start of the system, since you can get

with this 32-bit value but only 2 ^32 milliseconds can be used to specify,

which corresponds to 49.71 days, you can use this function only to do this,

read the time already with the help of this function to update, and is now an

offset is calculated at the beginning of the system time and always corresponds

to the difference of Millisekundenanteil indicating to system time.

In addition, the initialization of the time and also

the Ereignisdienstes starting values for the set, in order to save another

function call.

5: PAP of the time initialization

When you set the time, the global time variable

updated for seconds, and milliseconds. This also takes into account whether

Millisekundenanteile have been specified, the Not in the range 0 to 999. In

this case, a carryover for the seconds portion of is calculated, and the

Millisekundenanteil corrected accordingly.

But it is only the time of the OSA+ internally changed

- the general CMOS clock of the computer remains untouched.

The time periods necessary to offset the difference

between milliseconds of the system and the real time, must also be newly set so

that it does not come to the wrong calculations.

When reading the time, the global variable for

seconds and milliseconds updated. For this purpose, the difference in

milliseconds since the last time the query with the help of the system time

calculated and added to the current time.

Since the system time to calculate is used, it should

in fact not later than 49 days all the time query be invoked once, but now that

the event service is associated with the time, it can be ausgegeangen that this

due to its timer is called more often, in order to start the events correctly,

it must also of course at each time, in the course of which he is called from

the timer, the time queries, which is now the reason for this, that the time of

an application program does not necessarily have to be called regularly.

6: PAP of

the time

This function adds to the current time a specified

time difference in addition to this, in principle, this function does not have

been necessary, since one with the two above functions exactly the same thing

can reach had - but so is now saved time, and this may be to match the time on

the network can be of use, and the user will work when calculating the

carryover disconnected.

This function creates a string in which the

current date and time is included with milliseconds. ( This is especially handy

in debug output ). This is done by first with the help of the ctime from the

current time, in the 32-bit value is stored, generated a string, the date and

time already contains, the only thing missing now is the Millisekundenanteil,

which simply by various Stringkopieraktionen is inserted.

The event service is responsible for ensuring that

jobs at a specified time with a pre-specified accuracy can be started. He is to

guarantee the real-time capability of the OSA, which but limited by the

underlying operating system is, for jobs be started via the network, must,

however, only the clocks of the two systems are synchronized, this is by a

long-term observation of the Pingzeiten possible; as a result of the time

offset can then be calculated by which the current time has to be postponed, an

alternative would be the average of the Pingzeiten to calculate the last few

minutes, and with this to synchronize the clocks.

The event service is from Geschwindigkeitsgunden

directly in OSA have been implemented, it is therefore not directly to a

LW/HW-service, but rather a supplement to the OSA+ features available.

Figure 7:

Architecture of the Event Service (Ereignisdienst)

The initialization of the Ereignisdienstes is

automatically after the initialization of the time. This is the first to be the

necessary variables for the Eventing service set, the next step is the timer

function of the Ereignisdienstes started, what must be called upon regularly in

order to make it in time to start the jobs, in which intervals this is to be

called, depends on the desired accuracy of the Ereignisdienstes as well as the

speed of the underlying system, try showed that, for example on a Duron 900

even an interval of one millisecond is possible.

On a Pentium 100 products, on the other hand, only

5-10 ms intervals possible. ( but more about that later in the test runs.

It would also be conceivable, the performance of

the Ereignisdienstes to increase that zeitkirtische functions through the

implementation of assembly code are replaced.

When you add new events there are several possibilities:

The job can be either at a specific time, or with a relative delay be

called, and you can also be used to specify whether the job repeatedly in a

certain time interval is to be started (for example, is for the regular queries

of sensors helpful), and whether the result of the delivers to the later check

is to be saved, and also can be a optional to call a function if it

particularly in the short responses to local applications. When you add it can,

however, to get any error messages if the job was already over, the list is

full, or too many jobs at the same time are to be started, and this number in

the same time interval the job to be started is adjustable and should be to the

respective system be adapted to maintain speed and in addition must still be

given a timeout, the constrains the time window in which the job is to be

started.

The job is only called after leaving the window, so

is he skipped ( this happens but only if it to failures or malfunctions in

the system, the calling of the timer function prevent ). If it is a repetitive

job, it will be the next time but started again, and can still be set, if he is

as closely as possible to the Zeitgitter oriented, or the delay as precisely as

possible is to be met.

The Add/delete a job may be to delay a few

milliseconds, since, as long as the interrupt routine is active, no operations

on the list of job to be started are allowed, this of course also applies vice

versa for the interrupt routine, if you an insert/delete operation interrupts,

this call is ignored, which may of course have the consequence that a(IGE)

Event(s) to a few milliseconds late be started - what but only at very slow

computers into the weight cases is expected.

The job that you want to be the Ereignisdienstes in a

circular list managed fixed-size, you can, after you have been added to this

list, also again be removed - if you have not yet been started.

In order to results of the query again later delivers

to, is not yet an additional list managed, in the opened up for each event

to an entry exists (the key is the ID of the job), but for reasons of space is

only for each EventID keep the latest result.

If the size of the lists is to be changed, is that in

the source code simply by changing the #defines in the beginning to reach the files.

In addition, it can not - real-time operating systems

that have come to the timer not in time will be called; the result may be that

the events do not correctly can be started and is currently are then to be

started up to the point that started events at a time, i.e. as long as the

timeout of the respective jobs is not exceeded.

Another difficulty arises if a cyclic job has been

called for, the back is to be added to the list and an error occurs: a time

already past, crowded or list the already too many events to the desired time

be called, in order to solve this problem, is, at the moment a part installed,

the attempts to the event to matureness, later to start dates.

This will be calculated by either, that either the

next possible start times will be taken, or but in the set for the job by

increments is attempted, add the job again, the number of retries can be

adjusted - but should not be set too high, otherwise if there are too many

errors the time interval of the timer not longer sufficient, and the next will

be affected, if the rescue but is unsuccessful, the job will no longer be

called.

Back to an event from the table of the job to be

started to remove, first waited until requests on the table are allowed and

then occupied the semaphore.

The next step will be for the complete table, and

skipped the event you want to delete, and the remaining are automatically

when.

Now here is the error code returned, which when you

start a job is created, it can here, however, from being purged the last result

which emerged only be queried, and internally to a list of all mitzuloggenden

Events kept, in the then at the start of the event the result will be entered,

if there are more events will be logged, as the list is large, after the FI

Fo-Prinzip approach.

UINT osatime: Are Using Unixtime in seconds

UINT osamtime: related Millisekundenbruchteil (

<1,000 )

Osagettime: time reading

Osasettime: Time Set

Osaaddtime: Time-add offset

Osaprinttime:

Spend time

Osainitevents: Initialize event service and Time

Osadelevent: Delete Job

Osaaddevent: Add Job

Osageteventresult: Result of a running job reading

The configuration of the Ereignisdienstes within the

source code can be made, and by modifying the various definitions (

#define) at the beginning of the source code:

( Alternatively, these parameters from the source code

be relocated in the Makefile.

Variable instantaneous value

propositions

EVENTSPERTIME 5 :

determines the number of bootable events at the same time

TABLENGTH 255:

Indicates the size of the Event-Tabelle (must be a 2 ^n-1 number)

ERRORBUFFER 7 : Specifies the size of the

Result-Tabelle (must be a 2 ^n-1 number )

RETRYCOUNT 4 : specifies how often should be

attempted, a recurring event in the

List should be entered, if errors occur

OSA_DEBUG:

If defined, debug messages are issued, the

All of the important actions of the

Ereignisdienstes describe

Parameters:

None

Input

integer:NONE

Reads the current time from and updates the global

time variable ( osatime and osamtime ).

Implementation:

The time is almost to the millisecond, and is

calculated from a combination of the internal clock and the system time, the

clock will be at the beginning needed to fix the start time in seconds, but not

the accuracy is sufficient for OSA as a timer, in that, it not the time to the

millisecond that shows exactly, now here comes the system time in the game, the

milliseconds since the start of Windows in a 32-bit value, and if you now waits

until the clock the seconds count up to 1, then you can use it to calculate a

differential value to system time, and with the help of the value they get the

missing milliseconds for the time.

If so now osaGetTime() is invoked, the milliseconds

updated, and at a value greater than 1,000 according to also the seconds, and

the difference between this and the system time.

Parameters:Seconds,Milliseconds

Input

integer:NONE

Sets the time seconds is the time in the Unixformat

and milliseconds are the associated thousandth.

However, this change also directly to the events that

are already in the list are entered, and are to be started; i.e. it quickly in

case of major changes can lead to errors.

Implementation:

Here are the global variables are updated;

Millisekundenanteile greater than 999 will be automatically converted in

seconds.

Parameters:Seconds,Milliseconds

Input

integer:NONE

Added to the current time in addition to the time

difference of the call-up parameters milliseconds greater than 999 will be

converted to the seconds.

( Here are also negative values registered )

Implementation:

This function first reads the time from, and then

added the desired time difference, taking into account a Millisekundenuberlaufs,

added.

Parameters:Seconds and milliseconds of output time

Input integer:String with the date and time.

This function returns a pointer to a string, the

current date and time includes, in debug output is very helpful, since also

thousandths of a second to be issued.

Implementation:

The function will access the Function ctime

back, which from a 32-bit value (Epoch) a string with the date and time

calculated. This string will then be modified, so that even milliseconds with

be returned.

Parameters:

None

Input

integer:NONE

Initializes the table in which the jobs be entered

later and sets the time.

Implementation:

All of the entries will be first in the list of events

deleted, and the difference between the internal clock and the system time for

osaGetTime determined. The next step is now set the timer, later also the

starts the job, which is the Multimediatimer of Windows, the a function with a

definable accuracy can repeatedly. (image 5)

Parameters:assigned id1,NUMCOUNT ID

2,Type,start,MSTART, repeat,mRepeat, timeout, FUNCTION

Input integer:0 =OK, 1 =list already full, 2 =too many

events to the same Zeit,3 =time is already over

Assigned ID1,NUMCOUNT ID 2:ID's of the job that you

want to (ID1 is the normal ID of a job, ID2 is

For

the future of applications planned)

Type:Bit 0 =0:Start at the specified time (

Start,MSTART )

Bit

0 =1:Start in Start.MSTART Seconds

Bit

1 =0:start only once

Bit

1 =1:repeatedly at intervals of repeat.Start mRepeat

Bit

2 =0:return value of not logging osajbscdDeliver

Bit

2 =1:return value of osajbscdDeliver log for later queries (costs a little more

time.

Bit

3 =0:start times will be respected as precisely as possible

Bit

3 =1:time differences are maintained as closely as possible

Bit

4 =0:When Retries try,the job to start at the soonest Time

Bit

4 =1:In retries the job in time intervals of repeat.Try to start mRepeat

Start,MSTART:Start at/in Start.MSTART Seconds

Repeat,mRepeat:If

in type is specified, the event in repeat.mRepeat seconds called again

TimeoutGibt

the size of the time window, in milliseconds, in which the job is to be

launched

FunctionWenn

not zero, the specified function ( void function() ) called - osajbscdDeliver

is not running in the case

Adds a job to be launched to the Event List in

addition to this, the function can be specified the optional, but it is only

intended for local use, if short response times are of importance, this feature

is this, that you will be called directly, with the same priority as the timer

function of the Ereignisdienstes started ( on Windows, this is the the highest

). You should therefore not be longer than 1-5 ms to use it, as the

subsequent jobs this can be affected in some circumstances, since a while(1);

in this function, e.g. the system leads to Unbedienbarkeit, this option should

go directly to a function can only be used with extreme caution.

Implementation:

In order to prevent the paste that in between the

timer function on the Event List is accessing it, is a simple system with

semaphores implemented. This checks at the beginning of the paste

operation, whether the timer function is currently active and waiting if this

is the case, everything is free, the semaphore is occupied, and it can now be

checked whether it is possible to add the event, the list is already full, an

error will be immediately returned.

If not, now is the time for a relative time into an

absolute time converted so that can be compared quickly as possible, whether

the job is still is to run, or the time has already passed, the last thing now

to check, is the number of jobs, the at this time are to be started.

Now, if everything is in order, the job is in the Time

sorted list is inserted; this prevents that when starting from the correct

position must be sought.

Parameters:assigned id1,NUMCOUNT ID 2,start,MSTART

Input integer:number of the deleted events

Deletes one or more events from the list, or if one of

the parameters is 0 (up to the Millisekundenanteil), it is not compared; i.e. ,

osaDelEvent(0,0,0,0 ) Deletes the entire list, or if the time (start.MSTART) is

specified, it is always the absolute time compared ( even if the call the

relative is specified.

Implementation:

This function runs through the list of events from the

front to the rear, and not to delete the copied together events to be deleted

with the be skipped, and here again is the system used with semaphores, to

avoid conflicts.

Parameters:assigned id1, ID2

Input integer:result of the last Delivers

There is the latest result back, at the start of the

event with the assigned id1, ID2 has been created.

If OSA_ERR_SERVICE_NOT_FOUND is returned, the job was

either not started yet, or the result of change is already have been

overwritten.

Implementation:

The list is after the first event with the two ID's

being sought, and the returned result of the job in question, and when the

event is not found, the function returns OSA_ERR_SERVICE_NOT_FOUND back.

Void callback TimerProc(

UINT,UINT,DWORD,DWORD,DWORD )

This is the central function of the Ereignisdienstes,

which with the Multimediatimer from the desired accuracy of the

Ereignisdienstes regularly is called ( default are here 2ms ). It is

responsible for ensuring that the jobs to be started and repetitive jobs again

be entered in the list.

Implementation:

At the beginning of the function, it first checks

whether the semaphore is busy, and if so, this time interval is skipped;

otherwise is now checked, whether the first job needs to be started.

If yes, the next step is still being examined, whether

the timeout has not been exceeded and whether a function is to be called, or

the job is to be delivered (in the last case, optional, the result will be a

list saved).

It is a job to be repeated, again this is in the list,

taking into account the different operating modes, it is registered.

There are

several ways to do this, but one of the simplest is to set the time with the

help of the function osaSetTime ( seconds, milliseconds ).

For example,

is specified

Osasettime(

986604168, 50 )

So the clock

will be on

Friday the

06.April 2001, 4:42:48 PM set and 50 milliseconds.

However,

since this is not too comfortable, and most of the time almost is set

correctly, it is often better if the clock is not set to a new, but before

or is adjusted, the function is osaAddTime ( seconds, milliseconds ) provided.

So causes for

example

Osaaddtime (

-3600 , 0 )

That the

clock one hour is reset.

But you

need have no concerns that the time of the system of such actions could be

affected - the time is purely OSAintern.

Yet now, in

order to check that the Daylight Saving Time was successful, then the time you

can also still with the function osaPrintTime( seconds, milliseconds )

output:

Printf(" Date/Time: %s\n",

osaPrintTime( osatime , osamtime ));

Now here

is the first variant customizationsavailable presented:

A unique

feature is intended to be with a delay of 5 seconds will be called, is only

required once the function that should be called; this has, however, fixed

call, and with, here's a little example:

OSA_Error

test (void)

{

Printf( "Test OK\n" );

Return

OSA_ERR_OK;

}

Now, the

Eventing service still be communicated, where he finds the function, and

When he is to

call you, and this is done with

Osaaddevent ( 1, 0 , // assigned

id1, ID2

1

, // type ( bit 1 = 1, so start

time = delay.

5

, 0 , // start in 5 seconds

0

, 0 ,// time difference when repeats (if set)

1,000

, // 1 second timeout

&Test // Function

);

As the

start time is here now a delay of 5 seconds ( + 0 milliseconds ) as well as a

timeout of a second is specified at the end of the call must now only the

pointer to the function to be called be specified.

A timeout

of 1 second means that the function call to a maximum of 1 second may be

delayed - for larger delays he will no longer run.

Are Normal delays of 0-10 milliseconds; on fast systems (0-1

milliseconds.

The whole

sample program could then may then look like the following:

#Include "osa.h" // necessary include - Files

#Include "osa_ereignisdienst.h"

OSA_Error test (void)// function that the

event Service is Started

{

Printf( "Test OK\n" ); // as

soon as this issue is, the test was successful

Return OSA_ERR_OK;// everything OK

}

Main( )// Main Function

{

// Initialize the Ereignisdienstes

Osainitevents( );

// Test-Event

entries

Osaaddevent ( 1.0 , 1, 5.0 ,

0.0 , 1000, &test );

// ... And to

the start of the wait dfor

While(1)sleep(1000);

}

The next

example shows how to do a job programd, the will be called repeatedly, which is

to the test - function the first time after 5.050 seconds, and then repeatedly

at intervals of 1,005 seconds be called, the function is to be called

repeatedly, the Eventing service by setting the the 2, Bits communicated in the

display type box. The timeout is as well as in the previous example 1 second,

and in the display type box the bit 3 is not set, attempts of the Eventing

service here, the function exactly as possible to enter the vorherberechneten

time - in the present example : Start Time + 5.05 s + X * 1.005 p.

( If the

bit would have been set, he had tried, the delays exactly as possible.

The

description for the function here is to be called, you can see from the example

above, for example, here is the actual function call to the event Service:

Osaaddevent ( 1, 0 , // assigned

id1, ID2

1+2

, // type ( delayed start [Bit 1] +

repetition [Bit 2] )

5

, 50, // Start in 5.050

seconds

1

, 5 ,// repeated Start in 1.005

1,000 , // Timeout = 1,000

milliseconds

&Test // Function

);

If a job is

started, there is the possibility and subsequently the result query, which is

of the type OSA_Error. It plays no role, whether it is a deliver or a

direct function call has traded.

Osaaddevent (1.0 , 1+8 VDC , F2.0: , 0.0 ,50

, &test); // event in the list entries

Sleep(1000);

Printf( "Eventresult of ID 1 :

%d\n", osaGetEventResult(1.0 / * ID of the event * / ) );

Sleep(2000);

Printf( "Eventresult of ID 1 :

%d\n", osaGetEventResult(1.0 / * ID of the event * / ) );

In this

example is now the result once before, and the second time after the start of

the event read, and if everything is working properly, it is the first time

OSA_ERR_SERVICE_NOT_FOUND returned, since the results are not yet available,

and the second time then OSA_ERR_OK, what the return value of the test-function

corresponds to.

In the next

example will be added first three events, each of which every two seconds will

be called once. After 5 seconds, then two of the three will be removed again.

The associated program code could appear as follows:

Osaaddevent ( 1.0 , 1+2 ), "2, 0, 2.0

,50, &test1 ) ;// Add the 1 events.

Osaaddevent ( 1.0 , 1+2 ,2,500, 2.0 ,50,

&test2 ) ;// Add the 2 events.

Osaaddevent ( 2.0 , 1+2 , 3, 0, 2.0 ,50,

&test3 ) ;// Add the 3 events.

Sleep(5000); // wait for 5 seconds ...

Osadelevent ( 1.0 ,// and all with ID 1, *

Delete,

0.0 )

;// without the start times to be taken into account

When the

program starts, all three events will be initially launched sequentially. After

5 seconds are then the first two of the three events removed from the

list, as in the clearing instructions as the ID 1.0 was specified, what exactly

the ID's of the events corresponds to the start times were not taken into

account when you delete, since all passed with 0 fields cannot be compared.

Test Environments

System 1:

Hardware:

CPU:AMD Duron

800

Memory:256 MB

Hard Drive:10GB

Graphics:Nvidia Geforce 2

Operating system:

Windows 2000

System 2:

Hardware:

CPU:Cyrix 6x86

Memory:24MB RAM

Hard Drive:0.5GB

Graphics card: Tseng

ET6000

Operating system:

Windows 98

System 3:

Hardware:

CPU:Intel Celeron 450

Memory:256 MB

Hard Drive:100GB

Graphics:3dfx Voodoo 3000

Operating system:

Windows 2000

Configuration

of the Ereignisdienstes (if not otherwise specified):

Precision:2//

The Event-Timer is called every 2 milliseconds

EVENTSPERTIME:5//

it must not more than 5 events started at the same time

//

i.e. there will be maximum 5 events within the 2 ms started

TABLENGTH:255//

Number of entries in the Event-Tabelle (2 ^n-1 must be)

ERRORBUFFER:7//

number of jobs, the results keep at the same time

//

Should Be (must also be 2 ^n-1)

RETRYCOUNT:4//

Number of retrys if repetitive Job does not immediately return

// CAN BE ADDED

In this

test was done with the built-in local modified Serverfunktionstest. The

function this is not more testsrvFunc immediately, but only with the delay of 1

second will be called, by using the following changes in the File testsrv.c

were made:

If

(OSA_ERR_OK= =osajbscdDeliver(jobId))

{

... // Wait for

confirmation and result Queries

}

Has Been

Replaced by the following section

Osaaddevent(/

* ID * / jobId,0,

/

* Type * / 1,

/

* Delay * / 1.0 ,

/

* Repeat * / 0.0 ,

/

* Timeout * /1,000 to

/

* Feature * /NULL);

If(1)

{

... // Wait for

confirmation and result Queries

}

Now is the

result: (with debug mode enabled, to represent the timing of the procedure)

+ +> Added ID: 8524656 delay: 1,000 Start: Sun Apr

08 9:48 PM:41,917

--> Started Event 8524656 with error: 1ms at Sun

Apr 08 9:48 PM:41,918

Calculated 1+1

I received a 2!

+ +> Added ID: 8524656 delay: 1,000 Start: Sun Apr

08 9:48 PM:42,920

--> Started Event 8524656 with error: 0ms at Sun

Apr 08 9:48 PM:42,920

Calculated 2+1

I received a 3!

+ +> Added ID: 8524656 delay: 1,000 Start: Sun Apr

08 9:48 PM:43,920

--> Started Event 8524656 with error: 0ms at Sun

Apr 08 9:48 PM:43,920

Calculated 3+1

I received a 4!

As you can

see, the test was successful, and also the temporal error that start when you

are born, were within the tolerance: at a set of 2 Accuracy of the

Ereignisdienstes milliseconds is a error of 1ms are allowed or not to be

excluded.

In this

test is the response of the Ereignisdienstes on longer breaks in the System

tested, and the duration of the interruption is in this test here in about 10

seconds, is checked, whether cyclic jobs after this interruption continue to be

started correctly. In addition, there will be a demonstration of how the set/do

not set of the 3, affects bits to the time difference.

First Test:

Bit 3 = 0

Here is the

associated function call:

Osaaddevent(/

* ID * / 1.0 ,

/

* Type * / 1+2,

/

* Delay * / 2.0 ,

/

* Repeat * / 0.10 ,

/

* Timeout * /10,

/

* Feature * / &test );

And

the result after the start:

+ +> Added id: 1 delay: 9 Start: Sun Apr 22 12:50

PM:28,290 2001

--> Started Event 1 with error: 1ms at Sun Apr 22

12:50 PM:28,291 2001

Test OK

+ +> Added id: 1 delay: 9 Start: Sun Apr 22 12:50

PM:28,300 2001

--> Started Event 1 with error: 1ms at Sun Apr 22

12:50 PM:28,301 2001

Test OK

+ +> Added id: 1 delay: 9 Start: Sun Apr 22 12:50

PM:28,310 2001

--> Started Event 1 with error: 9804ms at Sun

Apr 22 12:50 PM:38,114

-> Skipped due to timeout

+ +> Added id: 1 delay: 6 Start: Sun Apr 22 12:50

PM:38,120 2001

--> Started Event 1 with error: 0ms at Sun Apr 22

12:50 PM:38,120 2001

Test OK

+ +> Added id: 1 delay: 10 Start: Sun Apr 22 12:50

PM:38,130 2001

--> Started Event 1 with error: 0ms at Sun Apr 22

12:50 PM:38,130 2001

Test OK

+ +> Added id: 1 delay: 10 Start: Sun Apr 22 12:50

PM:38,140 2001

--> Started Event 1 with error: 0ms at Sun Apr 22

12:50 PM:38,140 2001

Test OK

Here you

can see now that lasted 10 seconds after the interruption of the job is no

longer started, because of the timeout has been exceeded, the time for the next

start is now calculated so that the 10ms - Zeitgitter is respected.

Second Test:

Bit 3 = 1

Here is the

associated function call:

Osaaddevent(/

* ID * / 1.0 ,

/

* Type * / 1 +2+8,

/

* Delay * / 2.0 ,

/

* Repeat * / 0.10 ,

/

* Timeout * /10,

/

* Feature * / &test );

And the Test Results

+ +> Added id: 1 delay: 10 Start: Sun Apr 22

9:36 PM:26,359 2001

--> Started Event 1 with error: 0ms at Sun Apr 22

9:36 PM:26,359 2001

Test OK

+ +> Added id: 1 delay: 10 Start: Sun Apr 22 9:36

PM:26,369 2001

--> Started Event 1 with error: 1ms at Sun Apr 22

9:36 PM:26,370 2001

Test OK

+ +> Added id: 1 delay: 10 Start: Sun Apr 22

9:36 PM:26,380 2001

--> Started Event 1 with error:. with EN 10204ms at

Sun Apr 22 9:36 PM:36,584 2001

-> Skipped due to timeout

+ +> Added id: 1 delay: 10 Start: Sun Apr 22 9:36

PM:36,594 2001

--> Started Event 1 with error: 0ms at Sun Apr

22 9:36 PM:36,594 2001

Test OK

+ +> Added id: 1 delay: 10 Start: Sun Apr 22 9:36

PM:36,604 2001

--> Started Event 1 with error: 1ms at Sun Apr 22

9:36 PM:36,605 2001

Test OK

+ +> Added id: 1 delay: 10 Start: Sun Apr

22 9:36 PM:36,615 2001

--> Started Event 1 with error: 0ms at Sun Apr 22

9:36 PM:36,615 2001

Test OK

In this

test is now to see that no Zeitgitter more is present, and after the delay of

10 seconds no correction is applied, deleted a part of the calculation, so that

this variant a little less processor time.

( However,

is expected only on very slow systems make itself felt.

Now here

is tested in multiple passes, how high the maximum frequency of the calls on

this system may be set, without that it comes to errors or problems.

The set of

precision timer Ereignisdienstes: 1 millisecond.

Precision:1//

The Event-Timer every millisecond is called

Cycle 1:

Set precision

of the Ereignisdienstes :1 millisecond (precision= 1)

Set time

difference of the Test-Events :1 millisecond.

Associated

function call:

Osaaddevent(

/ * ID * / 1.0

,

/

* Type * / 1+2,

/

* Delay * / 2.0 ,

/

* Repeat * / 0.1 ,

/

* Timeout * /10,

/

* Feature * / &test );

And the

result of the test:

...

+ +> Added id: 1 delay: 1 Start: Mon Apr 23 12:28

PM:36,643 2001

--> Started Event 1 with error: 1ms at Mon Apr 23

12:28 PM:36,644 2001

Test OK

XX> Event 1 emergency added - Time Over

+ +> Added id: 1 delay: 2 Start: Mon Apr 23 12:28

PM:36,646 2001

--> Started Event 1 with error: 0ms at Mon Apr 23

12:28 PM:36,646 2001

Test OK

+ +> Added id: 1 delay: 1 Start: Mon Apr 23 12:28

PM:36,647 2001

--> Started Event 1 with error: 0ms at Mon Apr 23

12:28 PM:36,647 2001

Test OK

...

+ +> Added id: 1 delay: 1 Start: Mon Apr 23 12:28

PM:36,652 2001

--> Started Event 1 with error: 1ms at Mon Apr 23

12:28 PM:36,653 2001

Test OK

XX> Event 1 emergency added - Time Over

+ +> Added id: 1 delay: 2 Start: Mon Apr 23 12:28

PM:36,655 2001

--> Started Event 1 with error: 0ms at Mon Apr 23

12:28 PM:36,655 2001

Test OK

+ +> Added id: 1 delay: 1 Start: Mon Apr 23 12:28

PM:36,656 2001

--> Started Event 1 with error: 0ms at Mon Apr

23 12:28 PM:36,656 2001

Test OK

...

As you can

see, does the start mostly, but it is out and back to errors, to now is the

result of such a high request to improve the accuracy, would be the first

consideration, to configure the job in such a way as to that of the Eventing

service always the interval of one millisecond complies with with these

settings, the test was not, however, the desired result, but there were still

the same error.

The real

problem here is that the performance was not sufficient, to all text output to

be carried out within a millisecond after the text output were omitted in part,

the test was almost flawless. There were still error on, but not more in

10ms increments, but only every few seconds; also the misconduct has improved:

were it to the top 2 more failures per error, it is the case in the following

test run only has one:

...

--> Started Event 1 with error: 0ms at Mon Apr 23

3:54 PM:29,198 2001

--> Started Event 1 with error: 0ms at Mon Apr 23

3:54 PM:29,199 2001

--> Started Event 1 with error: 0ms at Mon Apr 23

3:54 PM:29,200 2001

--> Started Event 1 with error: 0ms at Mon Apr

23 3:54 PM:29,201 2001

--> Started Event 1 with error: 0ms at Mon Apr 23

3:54 PM:29,202 2001

--> Started Event 1 with error: 0ms at Mon Apr 23

3:54 PM:29,203 2001

--> Started Event 1 with error: 1ms at Mon Apr 23

3:54 PM:29,205 2001

XX> Event 1 emergency added - Time Over

--> Started Event 1 with error: 0ms at Mon Apr 23

3:54 PM:29,207 2001

...

Cycle 2:

Set

precision of the Ereignisdienstes :1 millisecond (precision= 1)

Set time

difference of the Test-Events :2 millisecond.

Associated

function call:

Osaaddevent(

/ * ID * / 1.0 ,

/

* Type * / 1+2,

/

* Delay * / 2.0 ,

/

* Repeat * / 0.2 ,

/

* Timeout * /10,

/

* Feature * / &test );

And the

test results:

...

--> Started Event 1 with error: 0ms at Thu Apr 26

12:12:42,310 2001

+ +> Added id: 1 delay: 2

Start: Thu Apr 26 12:12:42,312 2001

--> Started Event 1 with error: 0ms at Thu Apr 26

12:12:42,312 2001

+ +> Added id: 1 delay: 2 Start: Thu Apr 26

12:12:42,314 2001

--> Started Event 1 with error: 0ms at Thu Apr 26

12:12:42,314 2001

+ +> Added id: 1 delay: 2 Start: Thu Apr 26

12:12:42,316 2001

--> Started Event 1 with error: 0ms at Thu Apr 26

12:12:42,316 2001

...

The test

was properly here, without that it came to any errors, i.e. , when working with

text files, at least on this system should be a time difference of 2 ms be

between 2 Jobs

Here is to

be tested, as the replacement of the operating system from Windows 2000 to

Windows 98 is noticeable.

Cycle 1:

Set the

precision Ereignisdienstes :10 milliseconds (precision= 10)

Set time

difference of the Test-Events :100 milliseconds

Function

call:

Osaaddevent(

/ * ID * / 1.0 ,

/

* Type * / 1+2,

/

* Delay * / 2.0 ,

/

* Repeat * / 0.100 ,// cyclic

call every 100 ms

/

* Timeout * /10,

/

* Feature * / &test );

Test run:

In this test

Sorry, no results could be collected, as the operating system is either refused

the Test ( The Multimediatimer has not been activated ), or, if this time

succeeded in, worked behind the exit and save the logs not, because the system

remained at once.

Cycle 2:

Set of

precision timer of the Ereignisdienstes: 100 milliseconds

Function

call:

Osaaddevent(

/ * ID * / 1.0 ,

/

* Type * / 1+2,

/

* Delay * / 2.0 ,

/

* Repeat * / 1.0 ,

/

* Timeout * /10,

/

* Feature * / &test );

Test run:

...

+ +> Added id: 1 delay: involving 994 Start: Mon

Apr 24 11:54 PM:07,000 1995

--> Started Event 1 with error: 6ms at Mon Apr 24

11:54 PM:07,006 1995

+ +> Added id: 1 delay: involving 994 Start:

Mon Apr 24 11:54 PM:08,000 1995

--> Started Event 1 with error: Note No. 4465ms at

Mon Apr 24 11:54 PM:12,465 1995// done manually delay

-> Skipped due to timeout

+ +> Added id: 1 delay: experienced 535 recorded

Start: Mon Apr 24 11:54 PM:13,000 1995

--> Started Event 1 with error: 6ms at Mon Apr 24

11:54 PM:13,006 1995

+ +> Added id: 1 delay: involving 994 Start: Mon

Apr 24 11:54 PM:than 14,000 1995

Started Event 1 with error: 1ms at Mon Apr 24 11:54 PM

...

The result

shows that it is still possible, on a Windows 98 machine with the OSA to

run event service, but may not be a high claims be made to the accuracy!

As there is

a on Windows NT-based operating system present, can already at the beginning

with a higher accuracy than in 9.3.2 be started.

Cycle 1:

Set precision

of the Ereignisdienstes :1 millisecond (precision= 1)

Set time

difference of the Test-Events :1 millisecond.

Function

call:

Osaaddevent(

/ * ID * / 1.0 ,

/

* Type * / 1+2,

/

* Delay * / 2.0 ,

/

* Repeat * / 0.100 ,// cyclic

call every 100 ms

/

* Timeout * /10,

/

* Feature * / &test );

Test run:

...

--> Started Event

1 with error: 1ms at Wed May 11 11:28:43,584 2001

-> Skipped

due to timeout

XX> Event 1

emergency added - Time Over

+ +> Added id: 1

delay: 1 Start: Wed May 11 11:28:43,585 2001

--> Started Event

1 with error: 1ms at Wed May 11 11:28:43,586 2001

-> Skipped

due to timeout

XX> Event 1

emergency added - Time Over

+ +> Added id: 1

delay: 1 Start: Wed May 11 11:28:43,587 2001

--> Started Event

1 with error: 1ms at Wed May 11 11:28:43,588 2001

-> Skipped

due to timeout

XX> Event 1

emergency added - Time Over

+ +> Added id: 1

delay: 1 Start: Wed May 11 11:28:43,589 2001

--> Started Event

1 with error: 2ms at Wed May 11 11:28:43,591 2001

...

For this

test it is clear that here, in this system even more errors have occurred, as

in the same test on the first system. In a further test run however, again, as

in 9.3.1 NFS Server Configuration file , that mainly blame the text

output is to the late call, the same test with only a text per call will be as

follows:

...

--> Started Event

1 with error: 0ms at Wed May 23 15:18:28,271 2001

--> Started Event

1 with error: 0ms at Wed May 23 15:18:28,272 2001

--> Started Event

1 with error: 0ms at Wed May 23 15:18:28,273 2001

--> Started Event

1 with error: 0ms at Wed May 23 15:18:28,274 2001

--> Started Event

1 with error: 0ms at Wed May 23 15:18:28,275 2001

...

So a much

better result ( Timeouts came even before, however very much less than

previously ). This is also the reason why should also sub-programs, the of of

the timer function in so called short intervals are not too to take a lot of

time.

Cycle 2:

In the

following test was now the Aufruffrequenz halved, to test whether this time the

attempt without Timeouts runs; the test environment is as follows:

Set precision

of the Ereignisdienstes :1 millisecond (precision= 1)

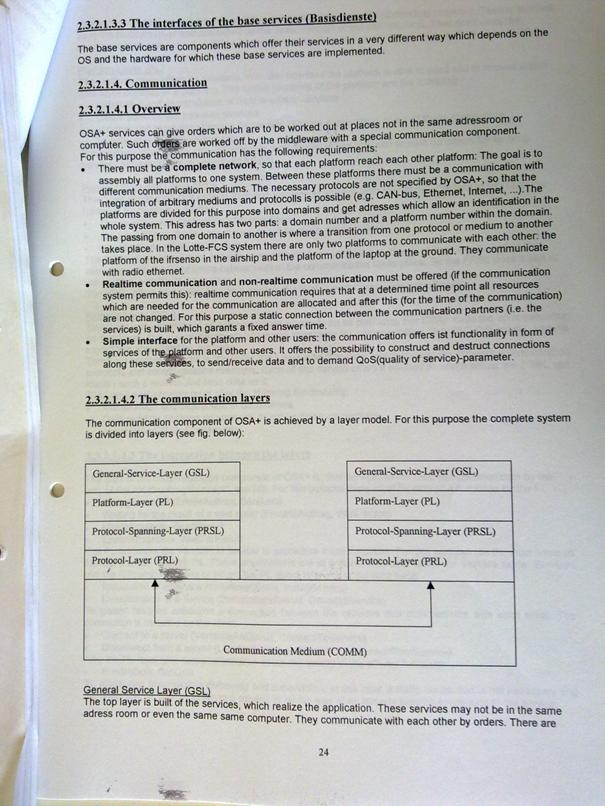

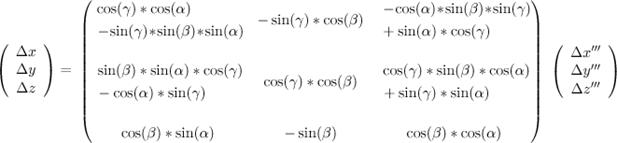

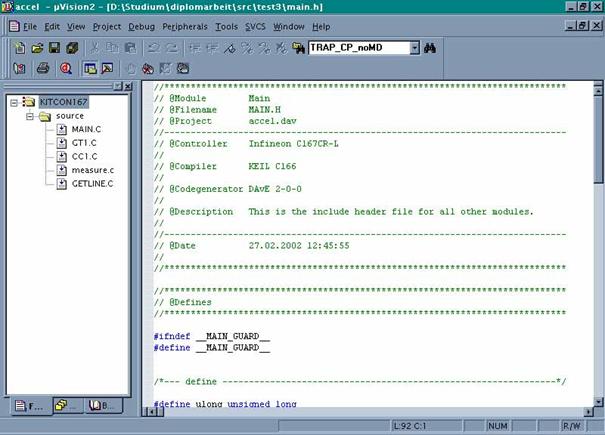

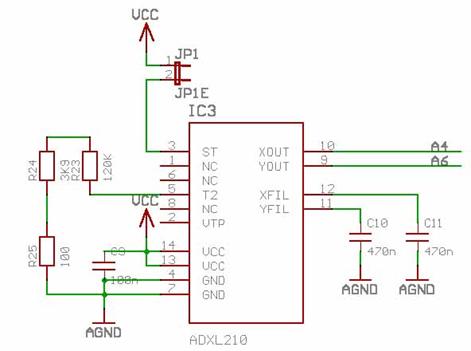

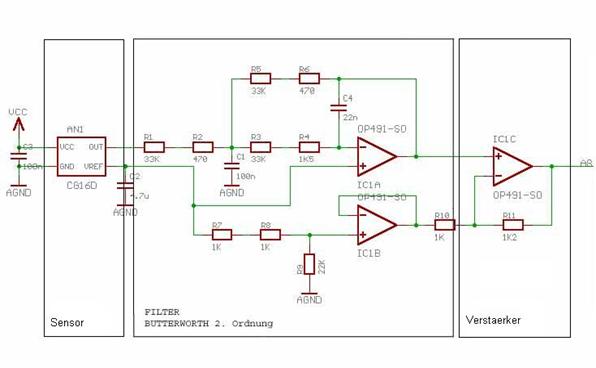

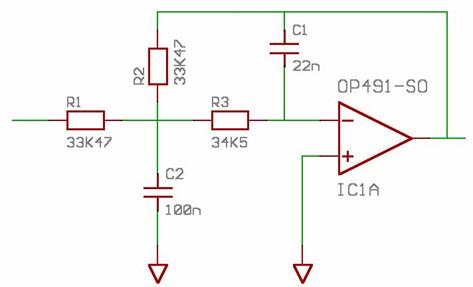

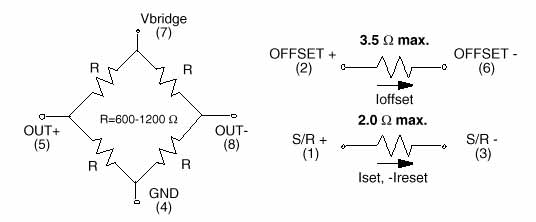

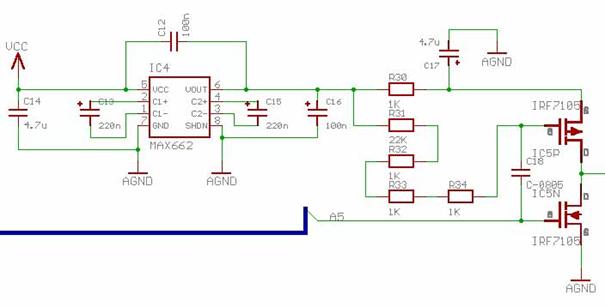

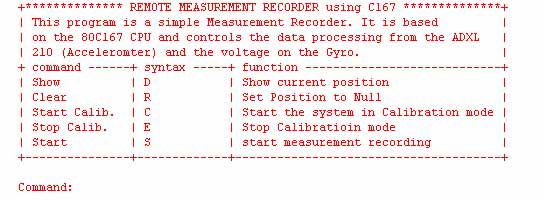

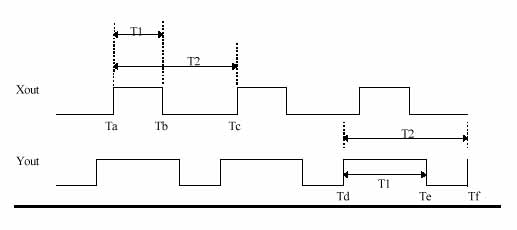

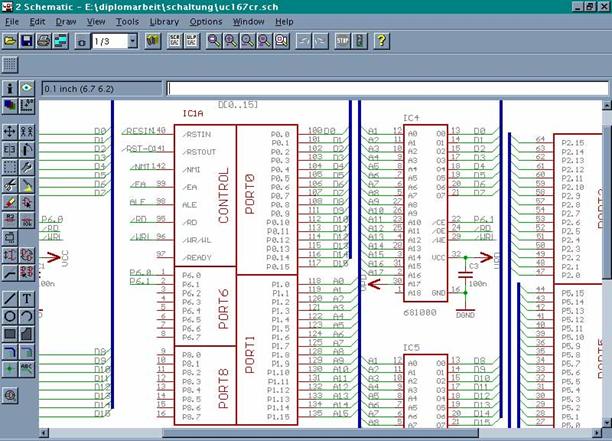

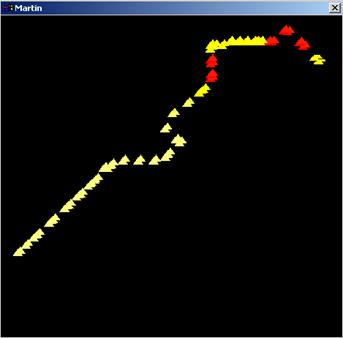

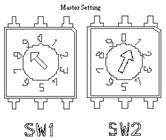

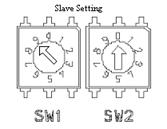

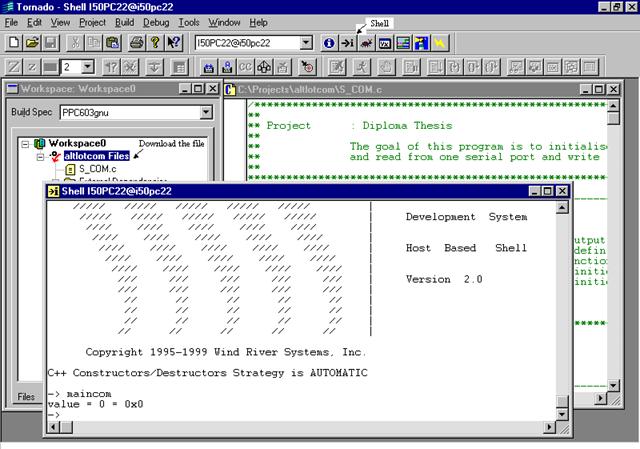

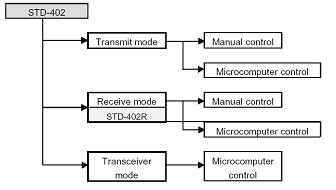

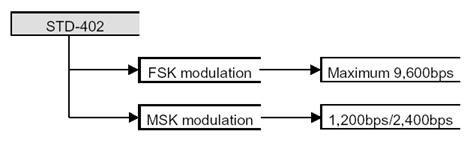

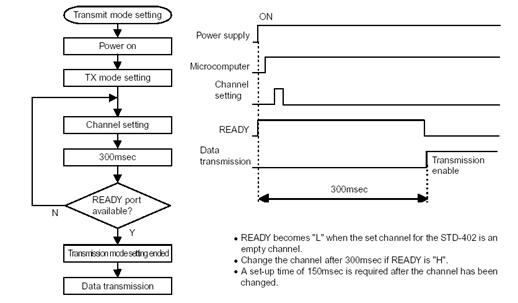

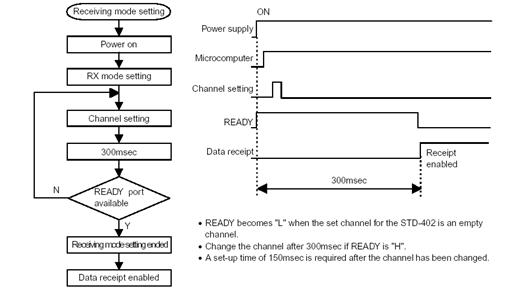

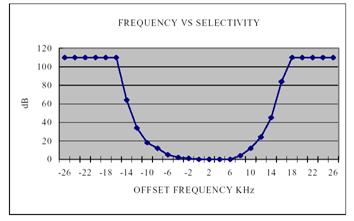

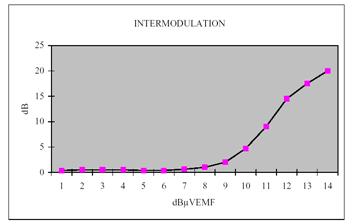

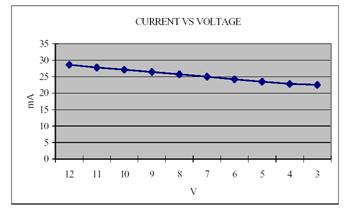

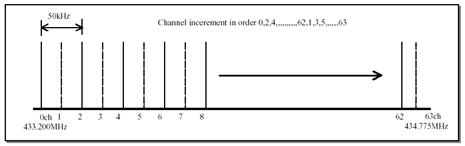

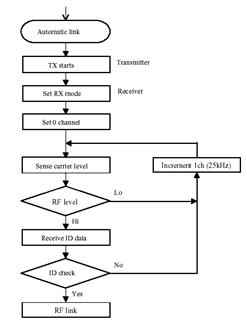

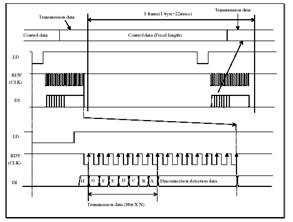

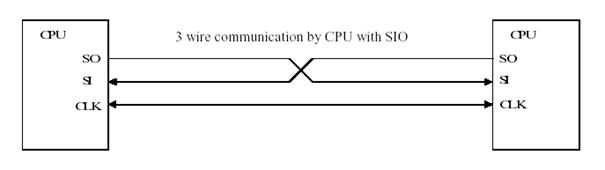

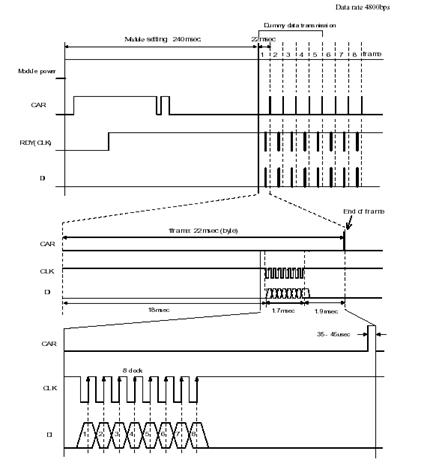

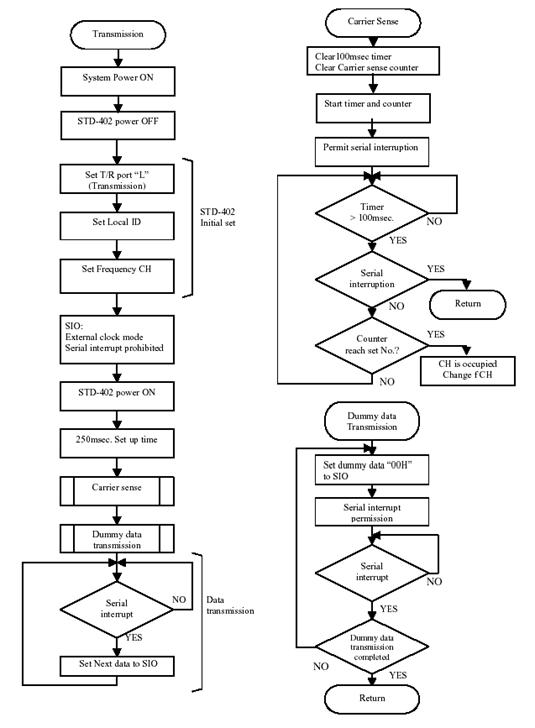

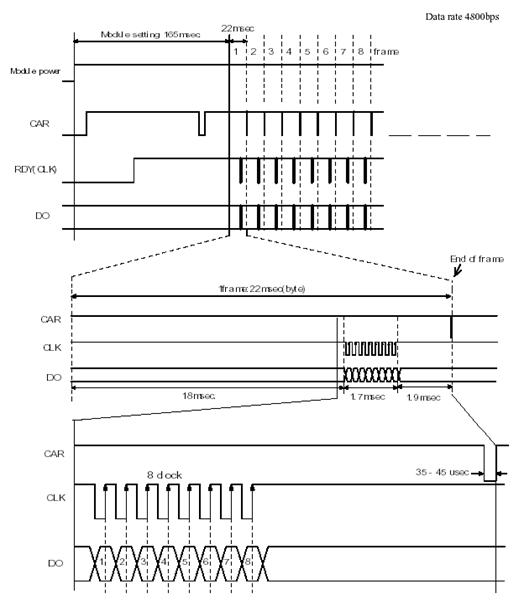

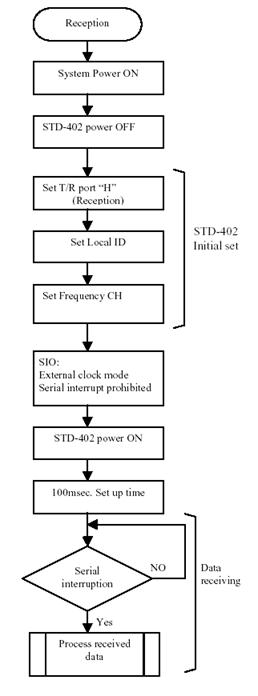

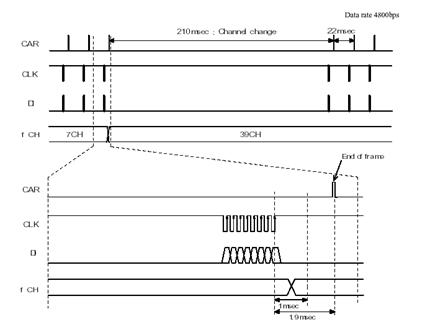

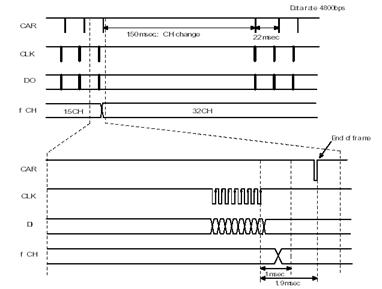

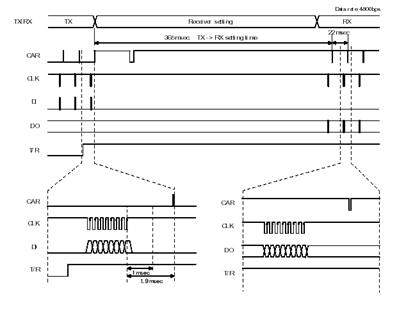

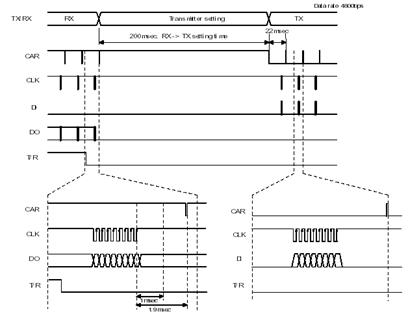

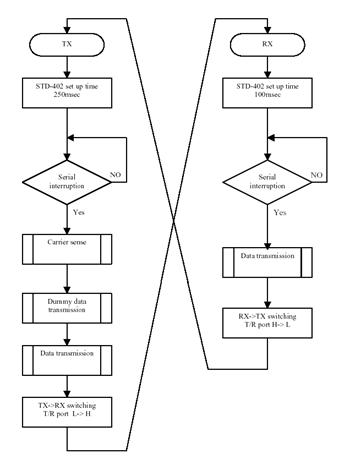

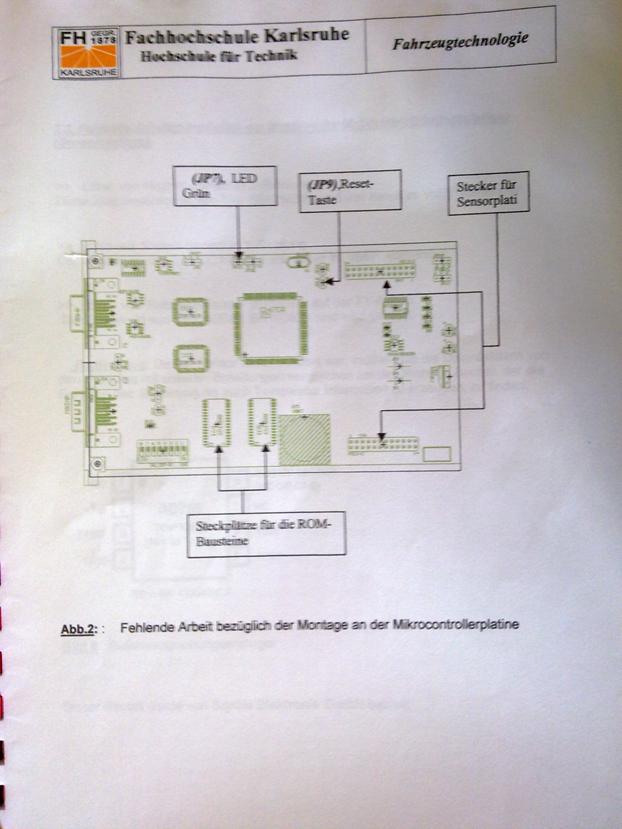

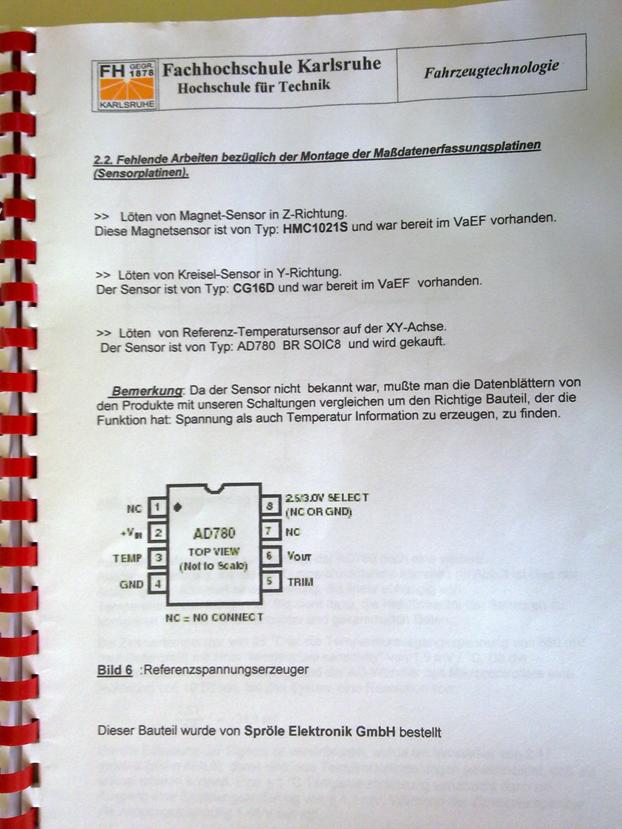

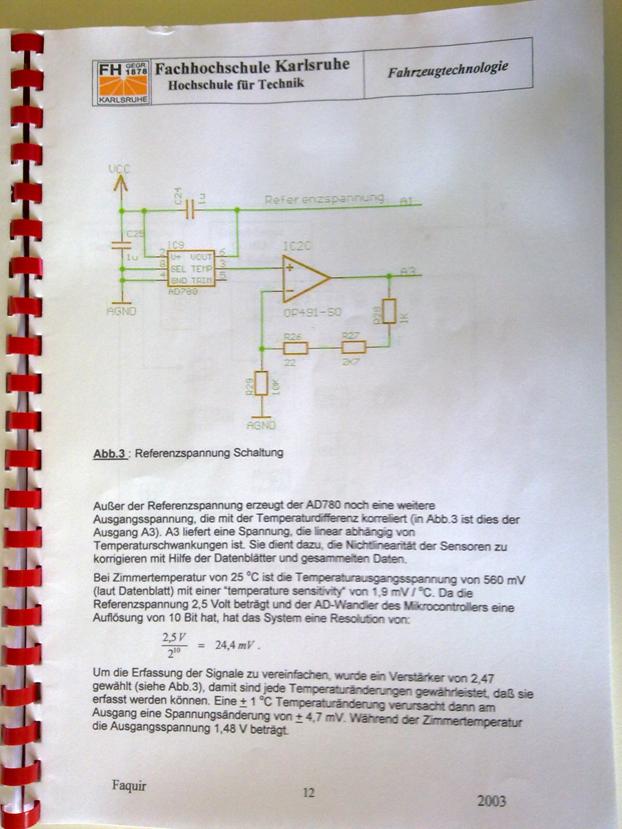

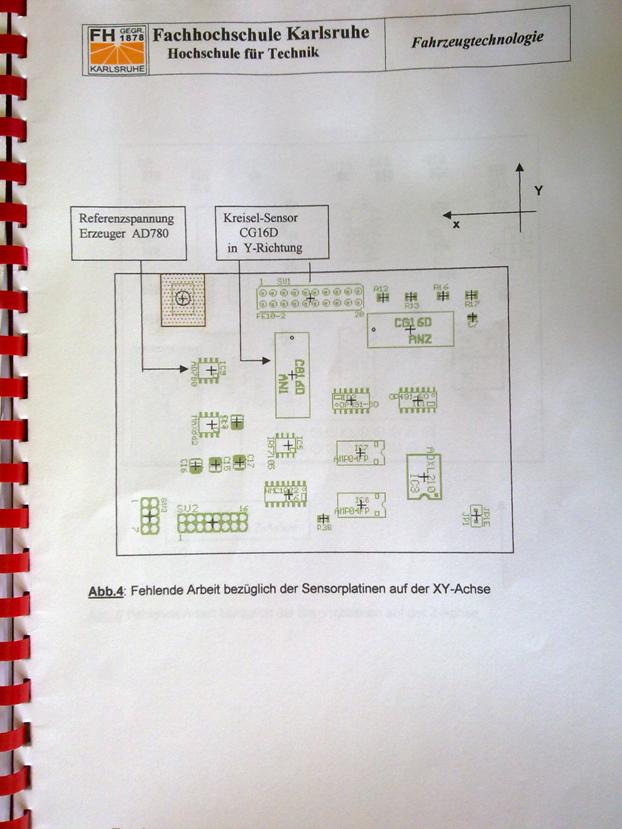

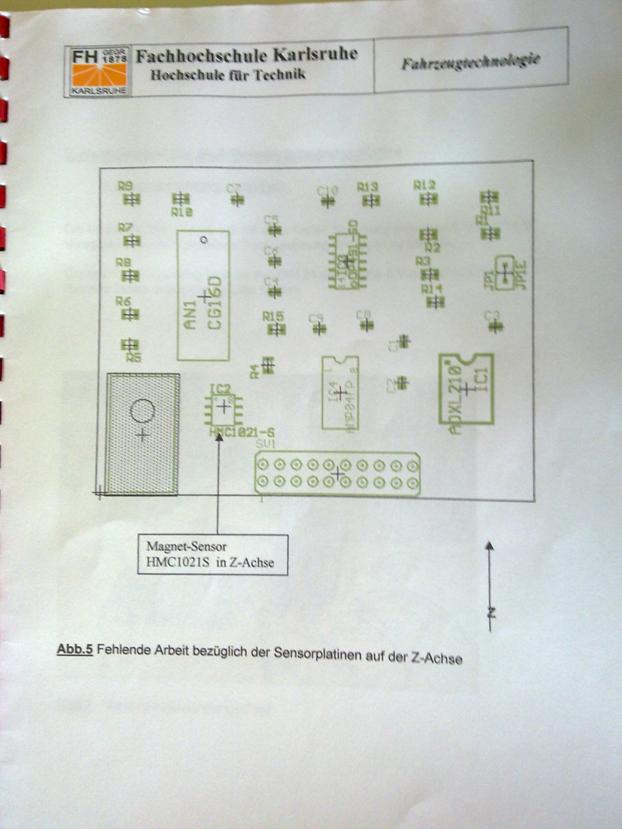

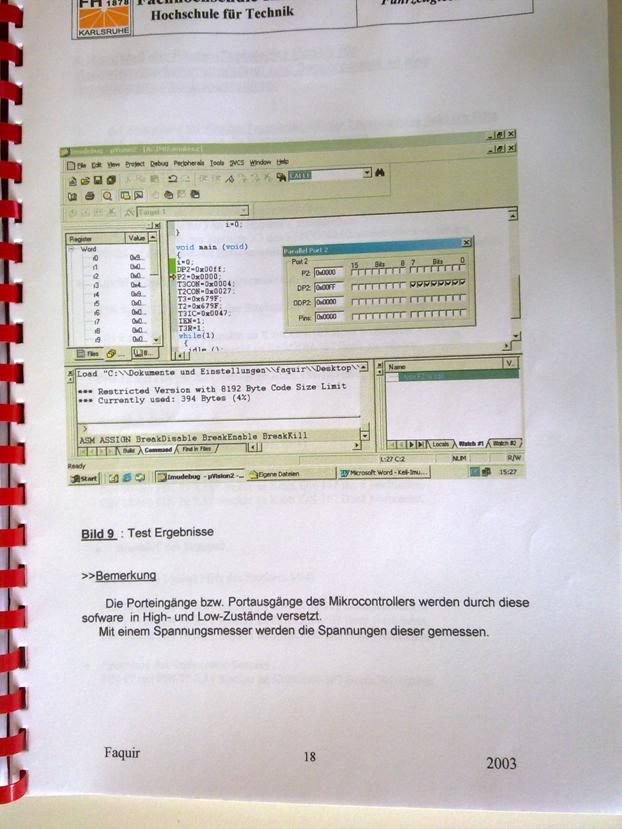

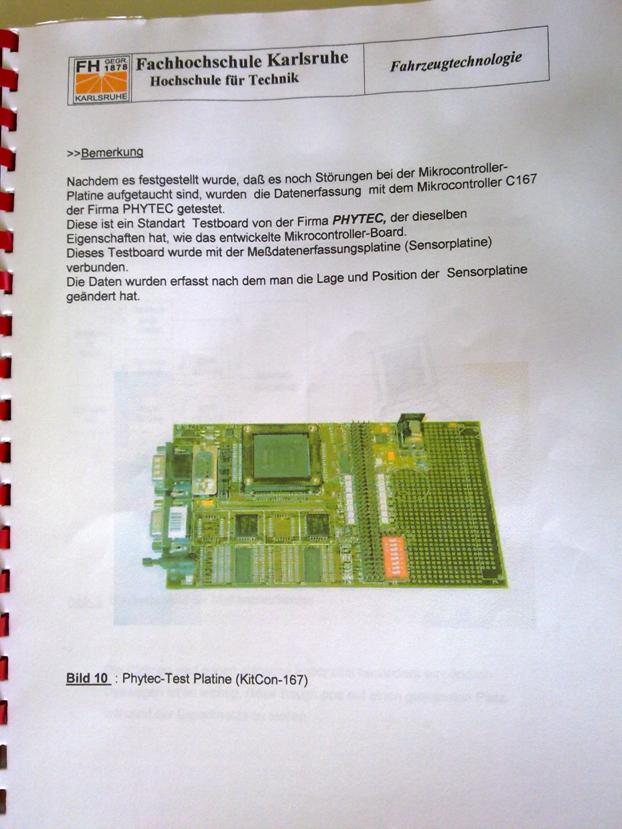

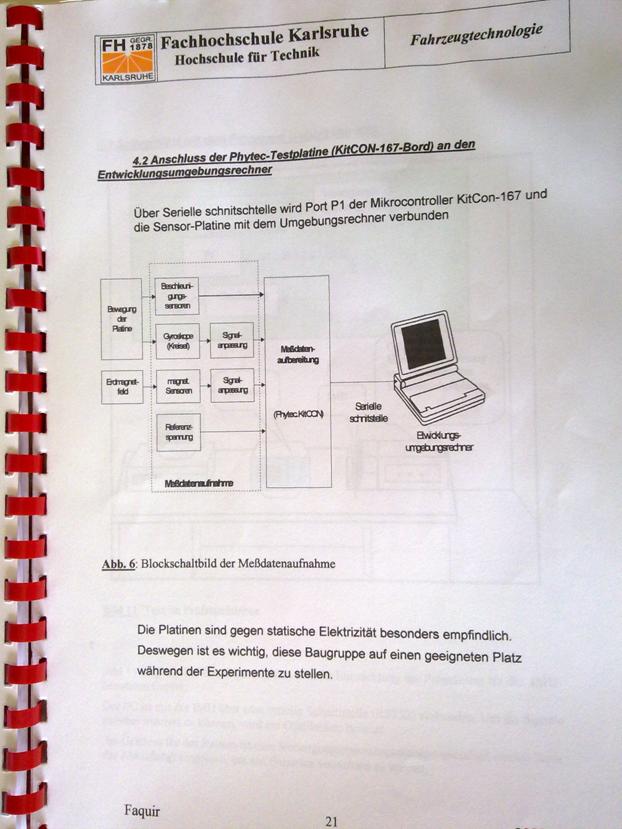

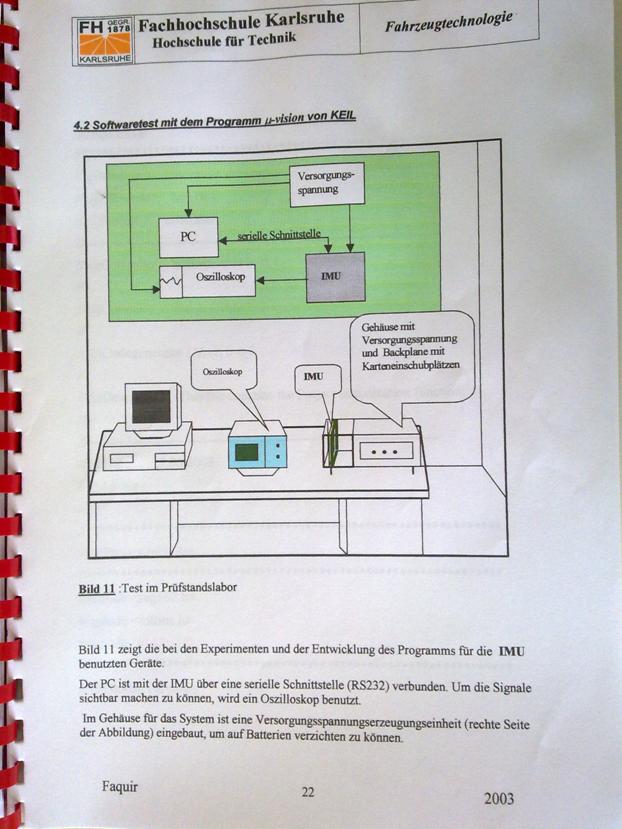

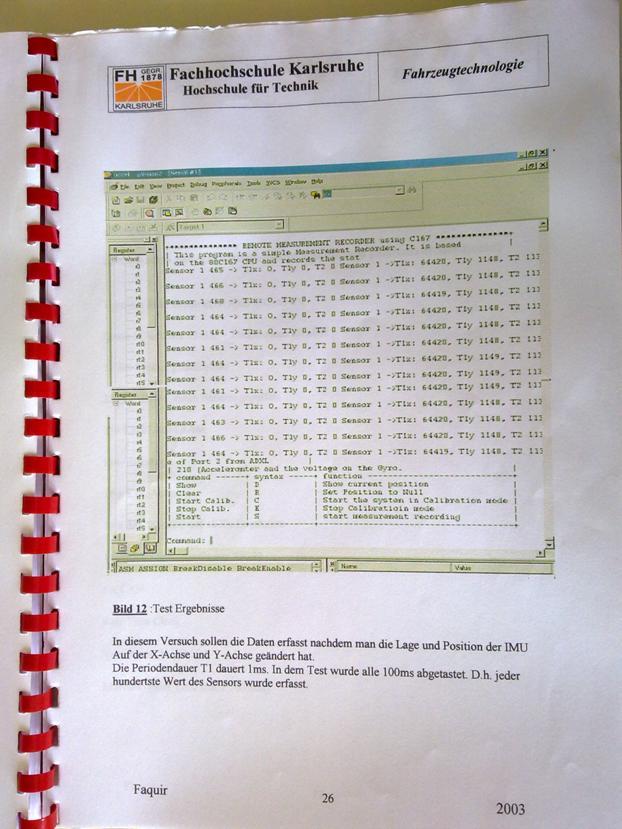

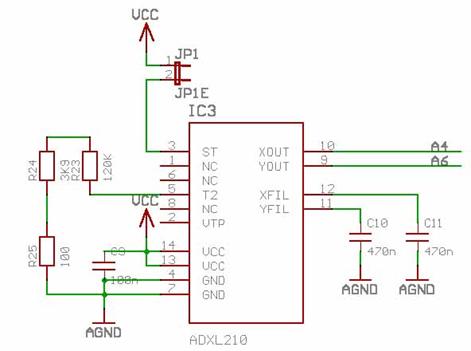

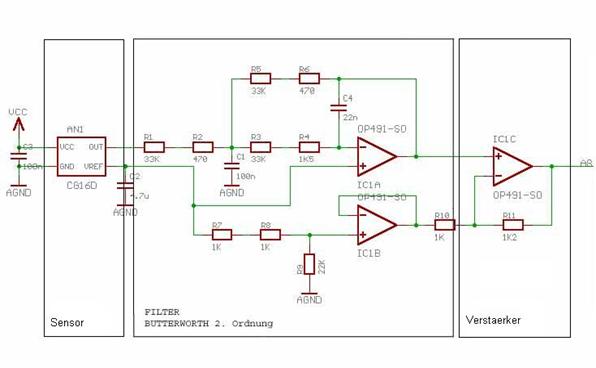

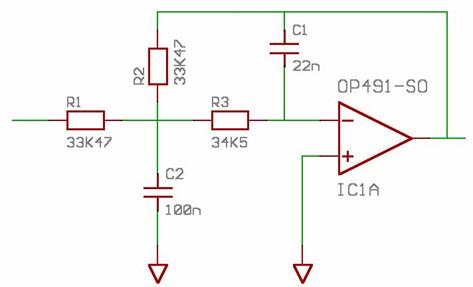

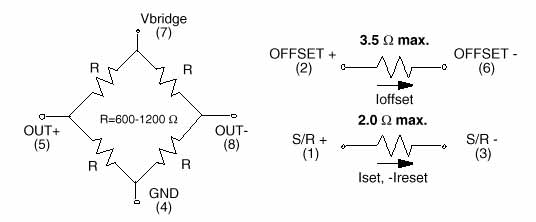

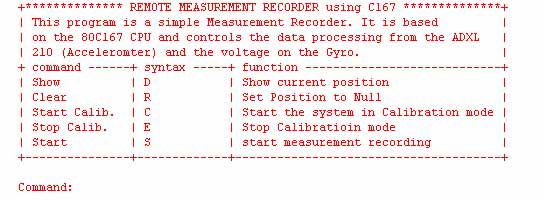

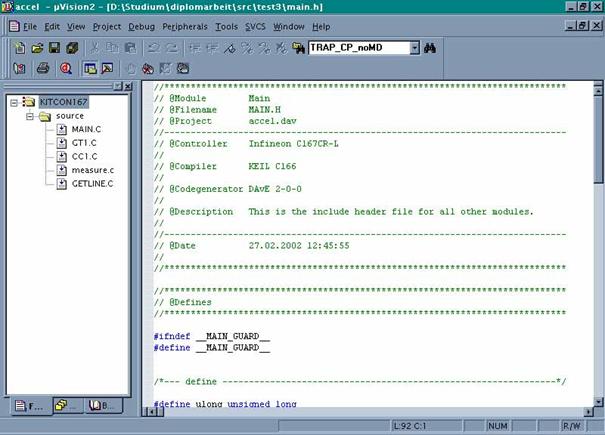

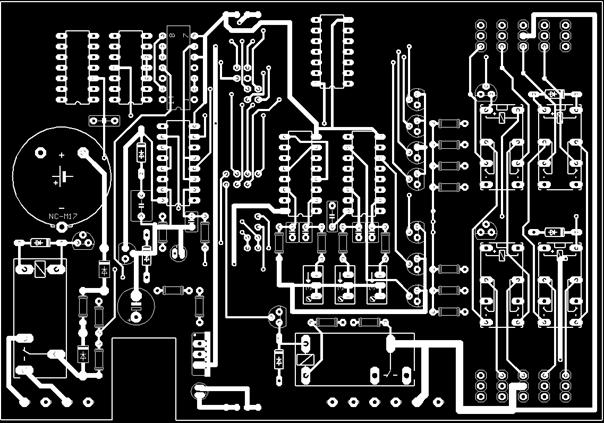

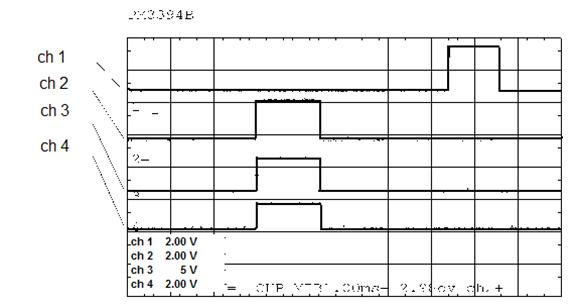

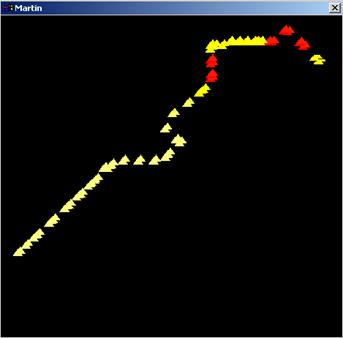

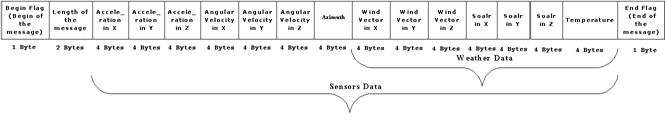

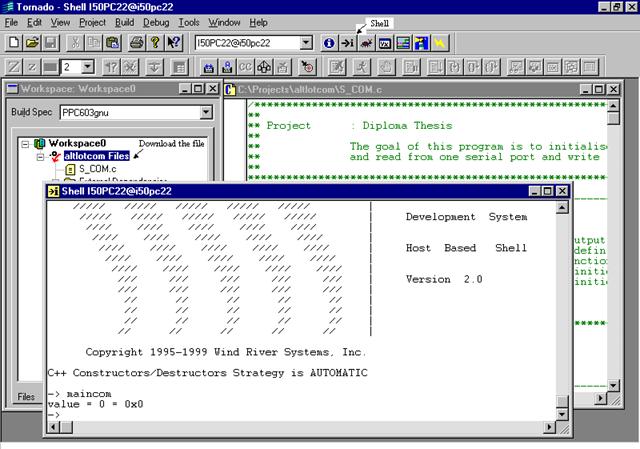

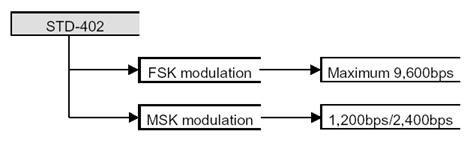

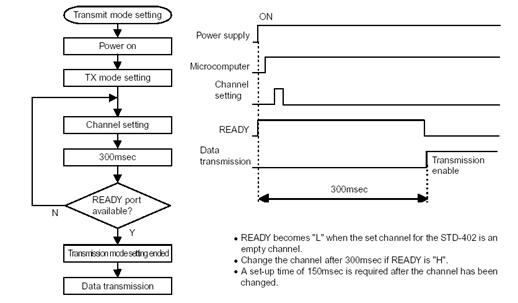

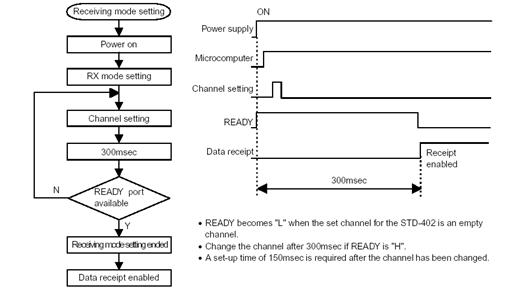

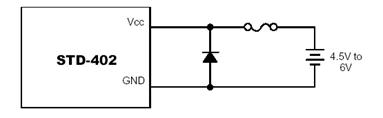

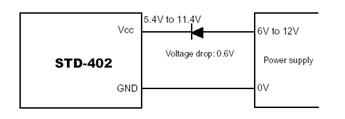

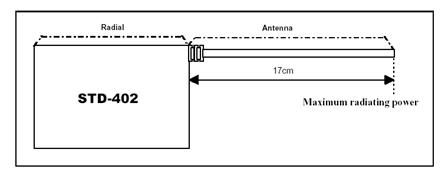

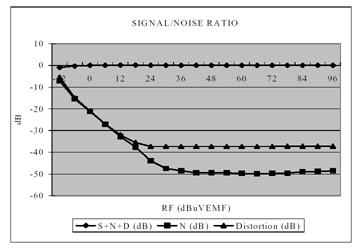

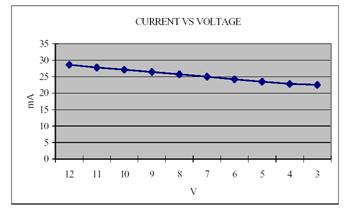

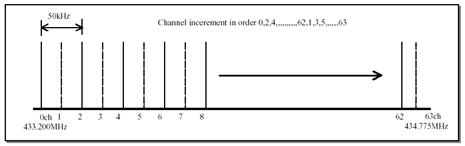

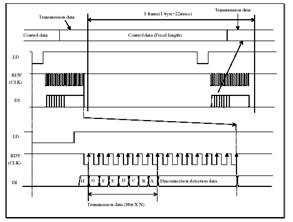

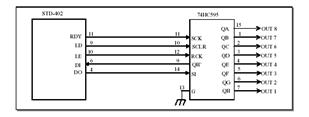

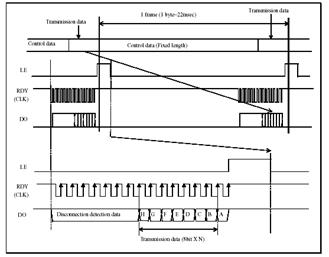

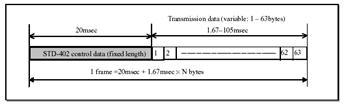

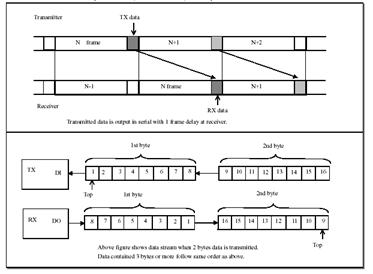

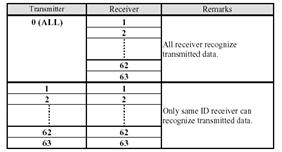

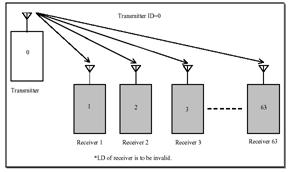

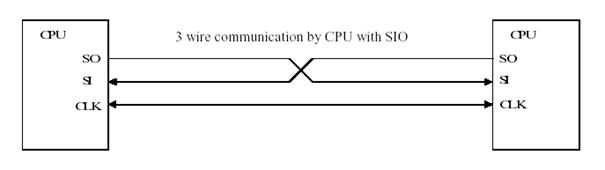

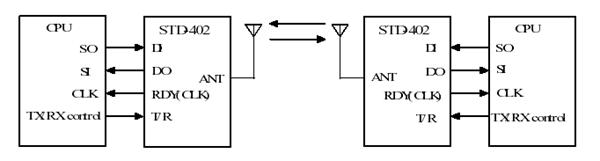

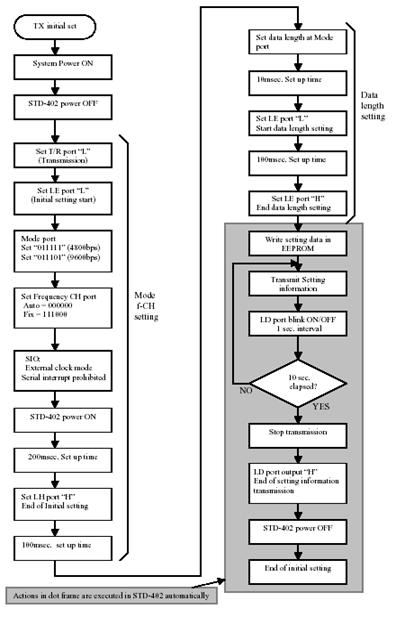

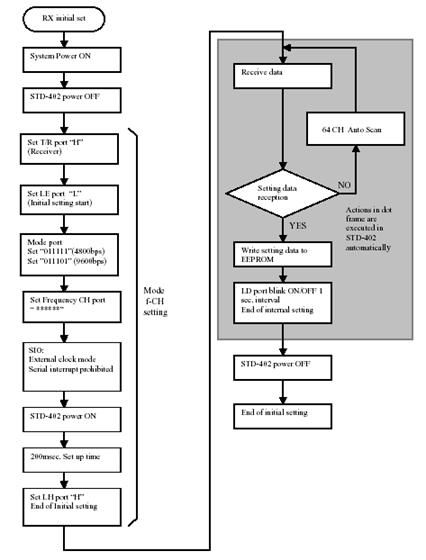

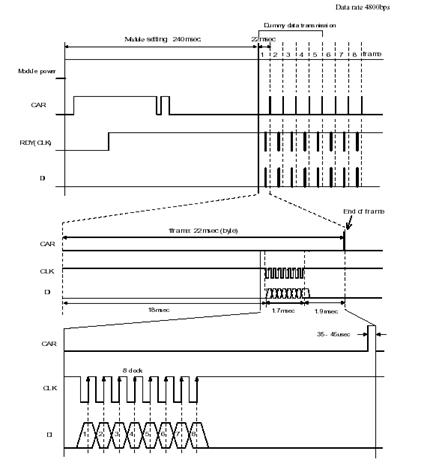

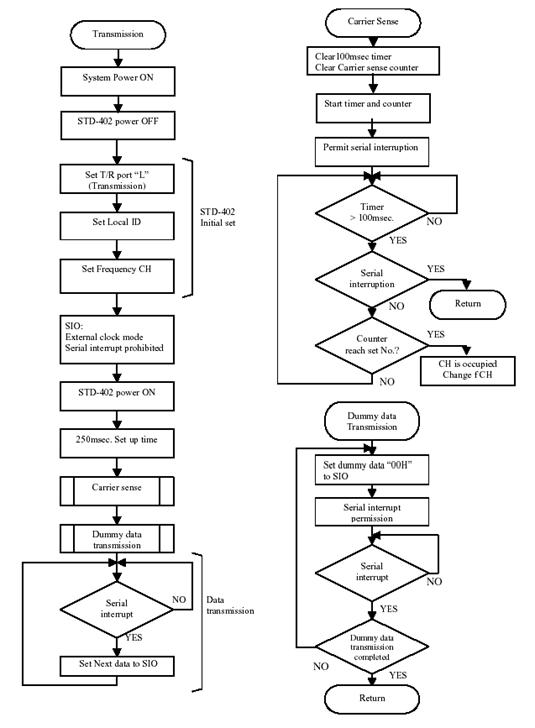

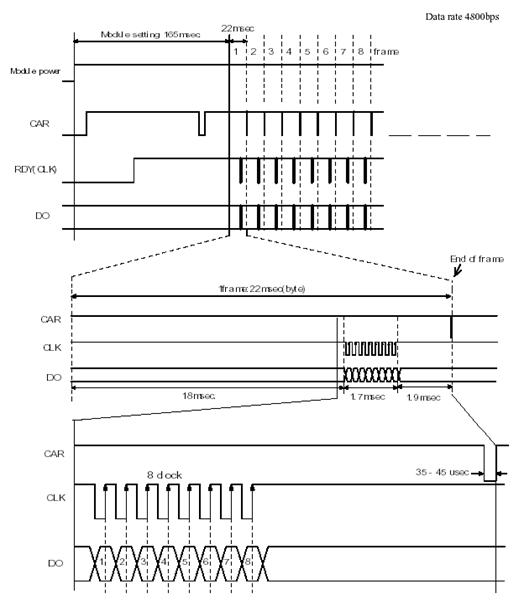

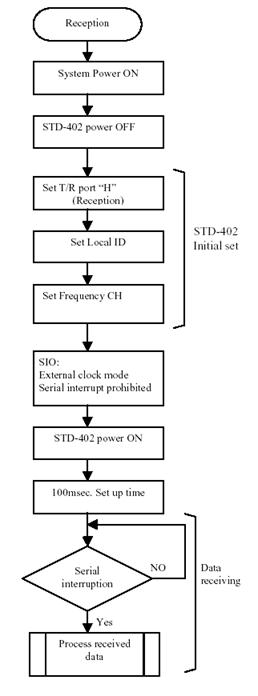

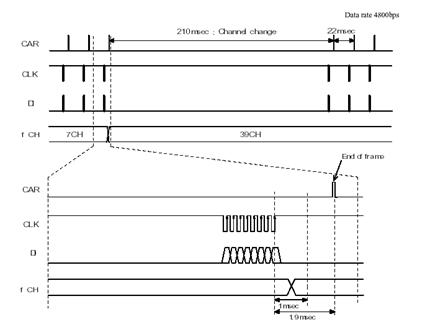

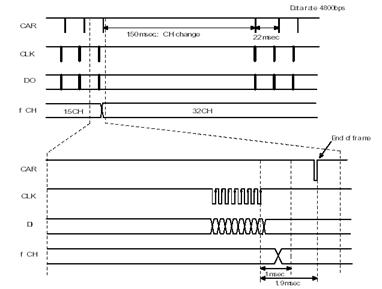

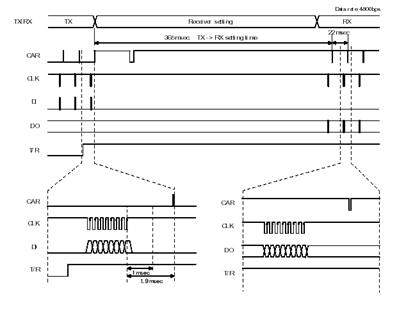

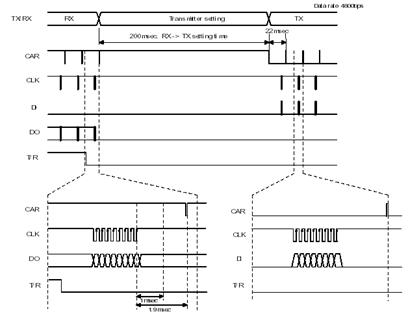

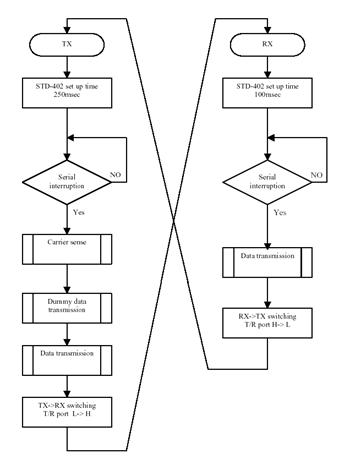

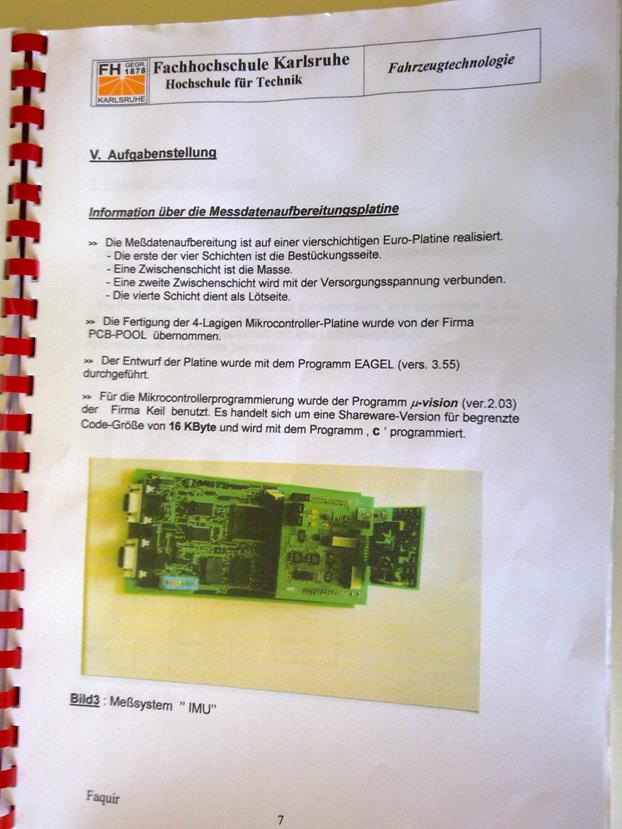

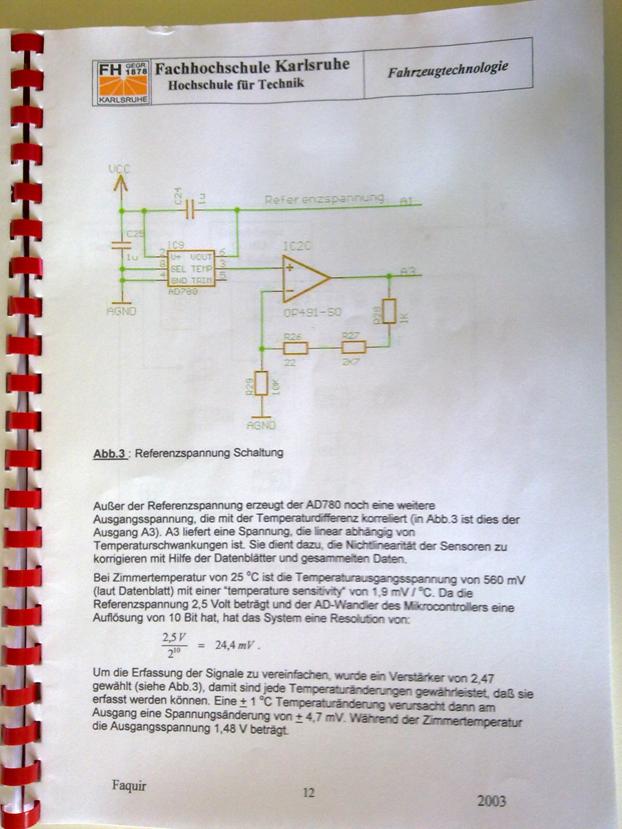

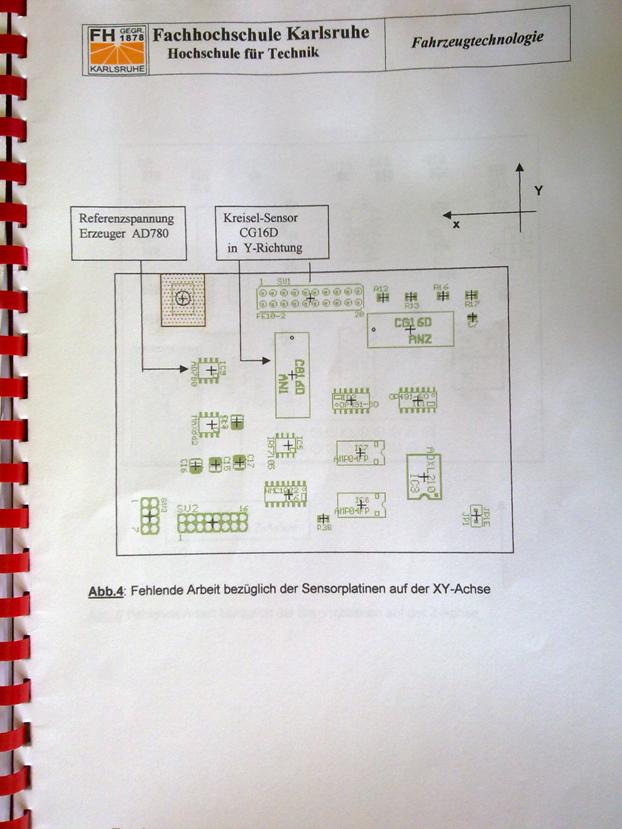

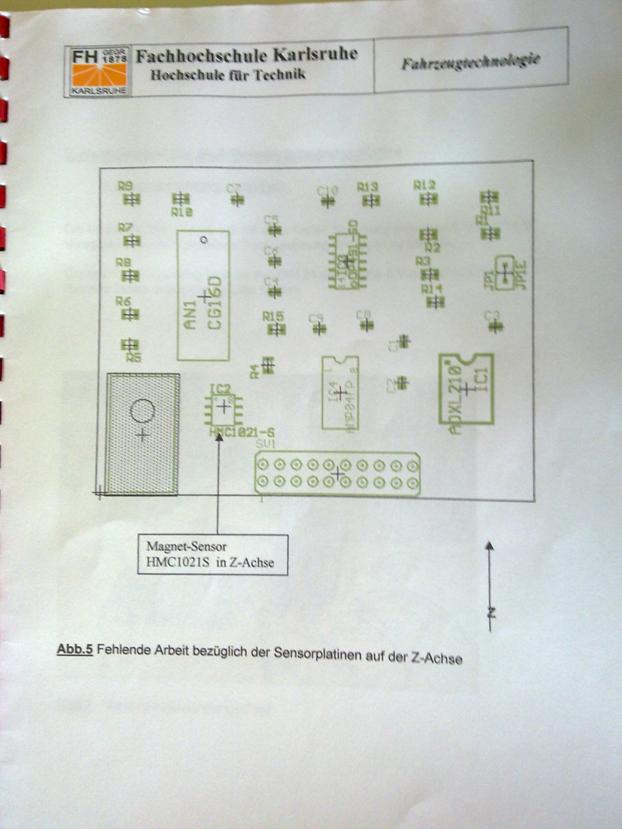

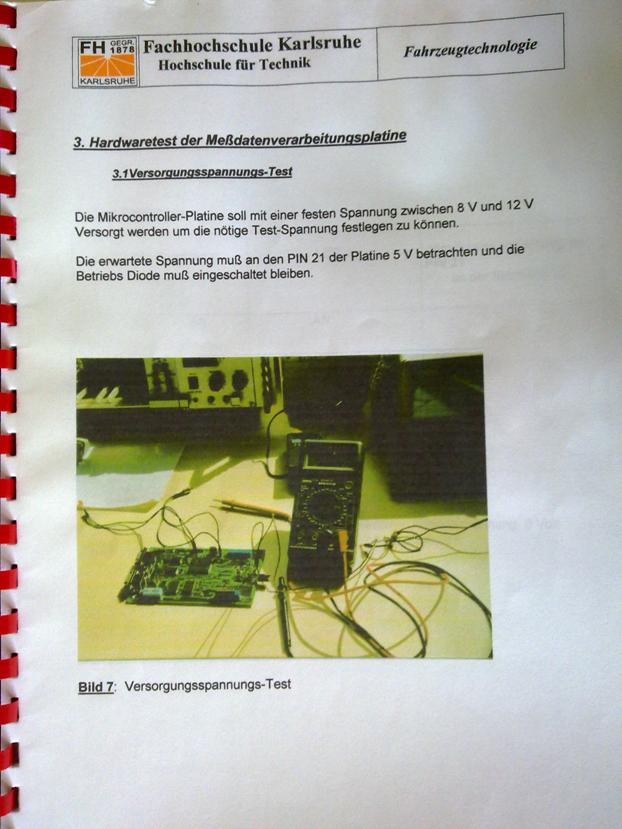

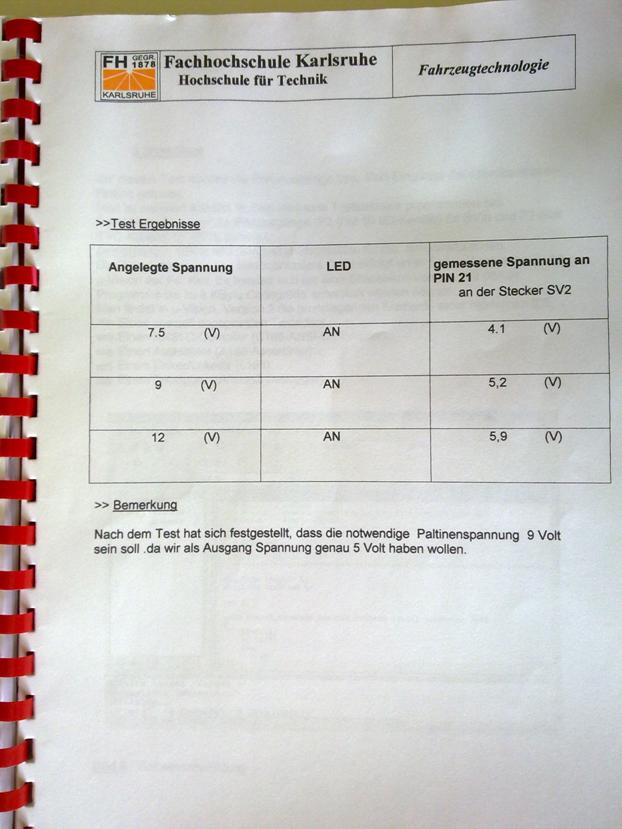

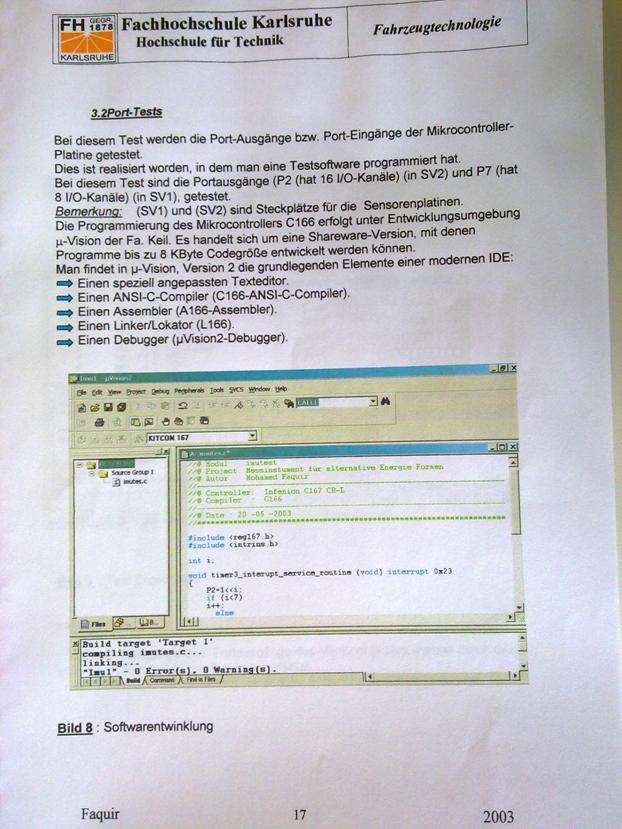

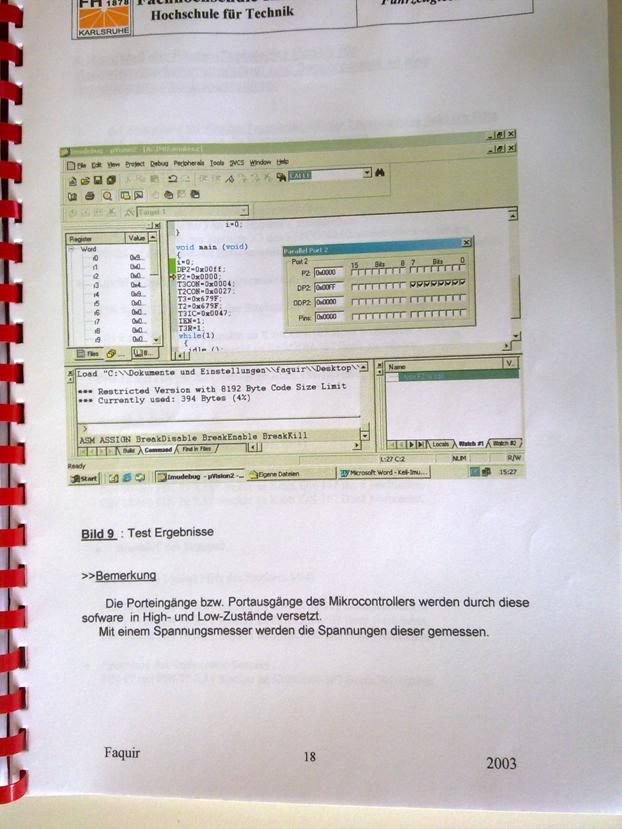

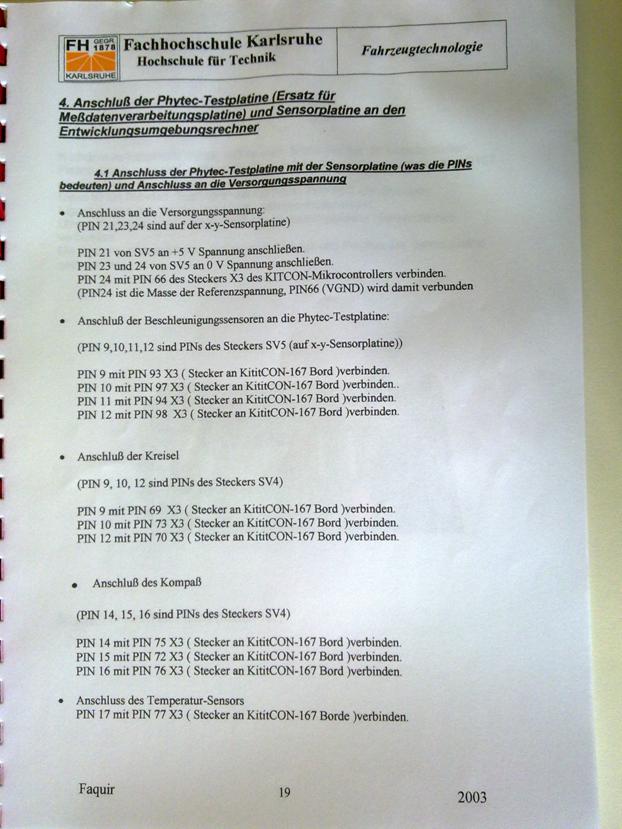

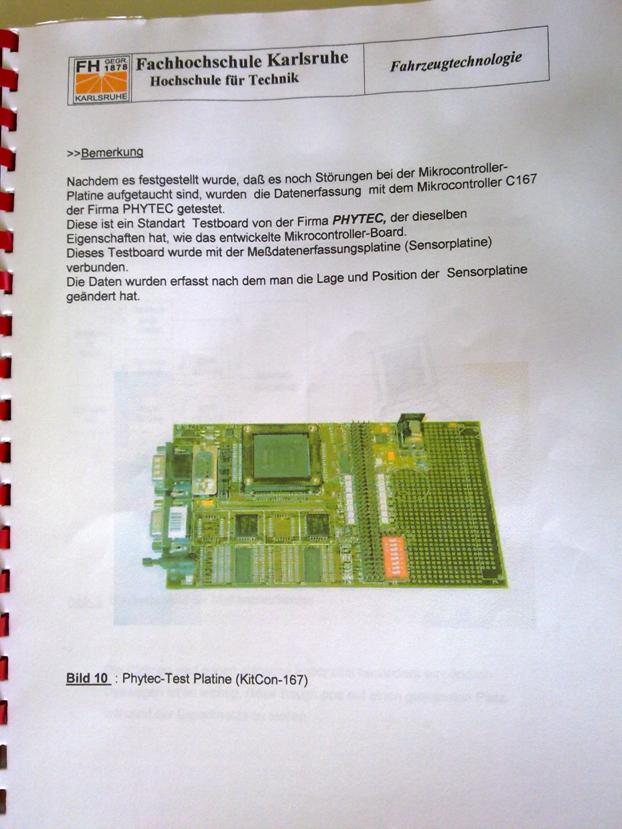

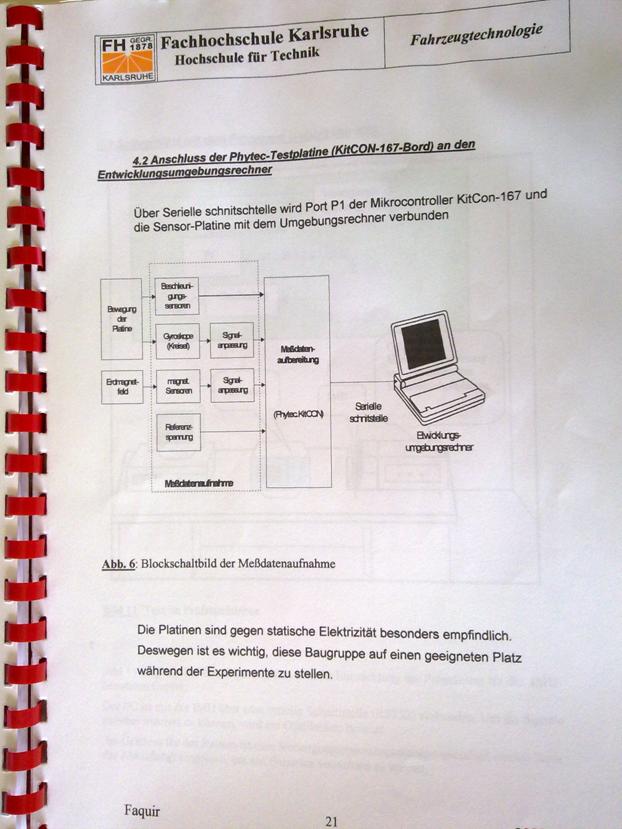

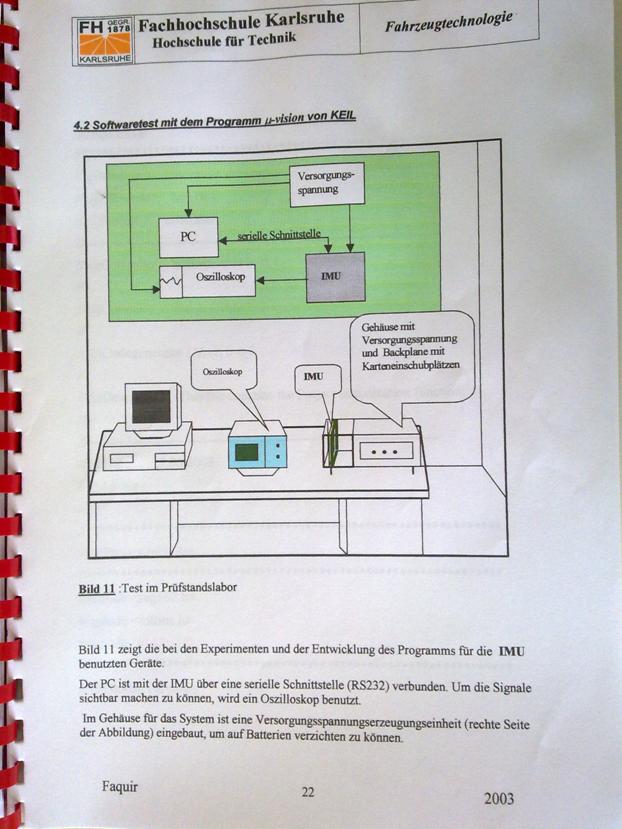

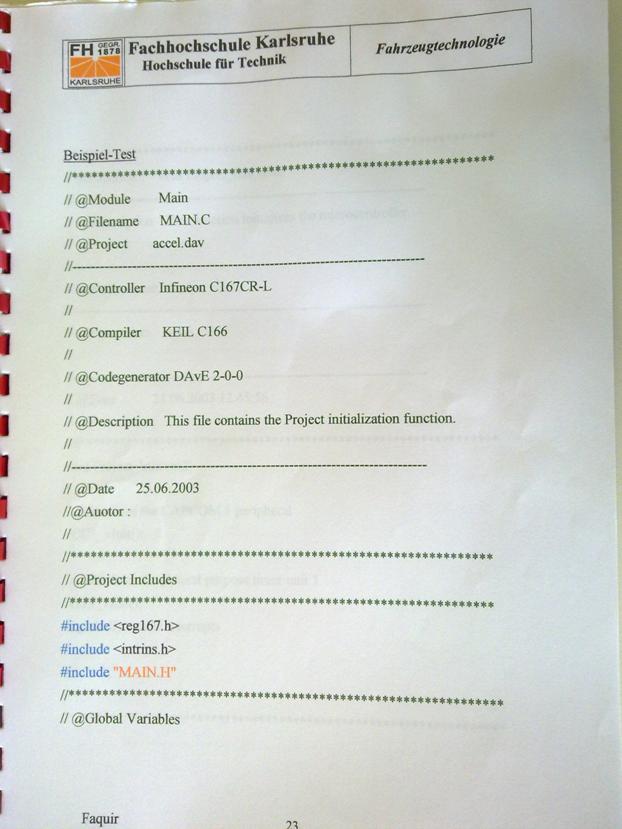

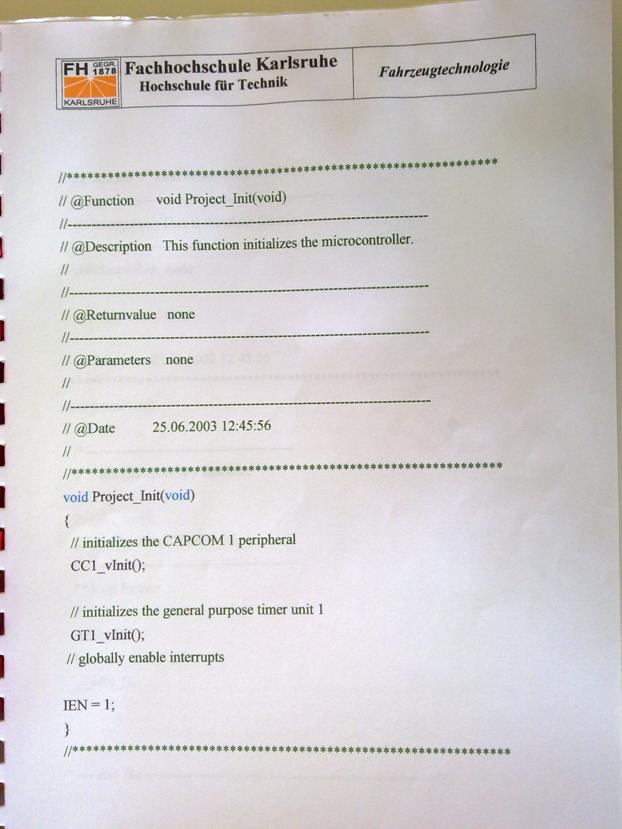

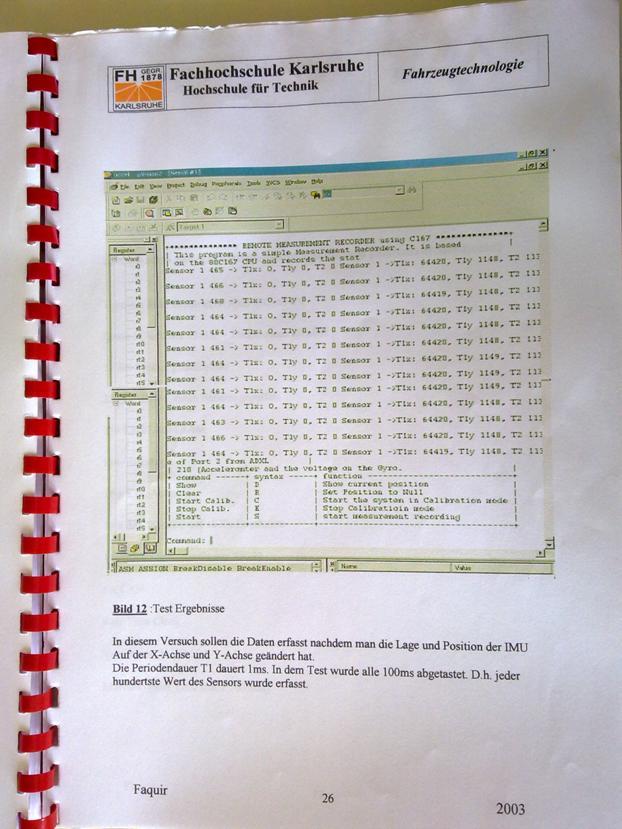

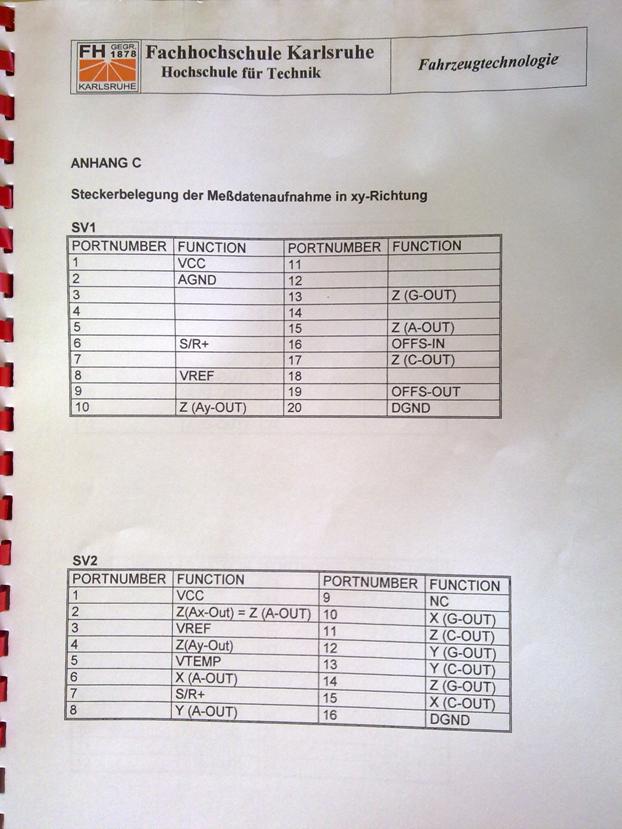

Set time